Method and device for measuring heat conduction coefficient of natural gas hydrate in porous medium

A technology of thermal conductivity and porous media, which is applied in the field of measuring the thermal conductivity of natural gas hydrate in porous media, can solve problems such as difficult measurement, complicated measurement and research of thermal conductivity, and imperfect heat transfer mechanism of hydrate-containing porous media, etc., to achieve Improved uniformity, safe and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

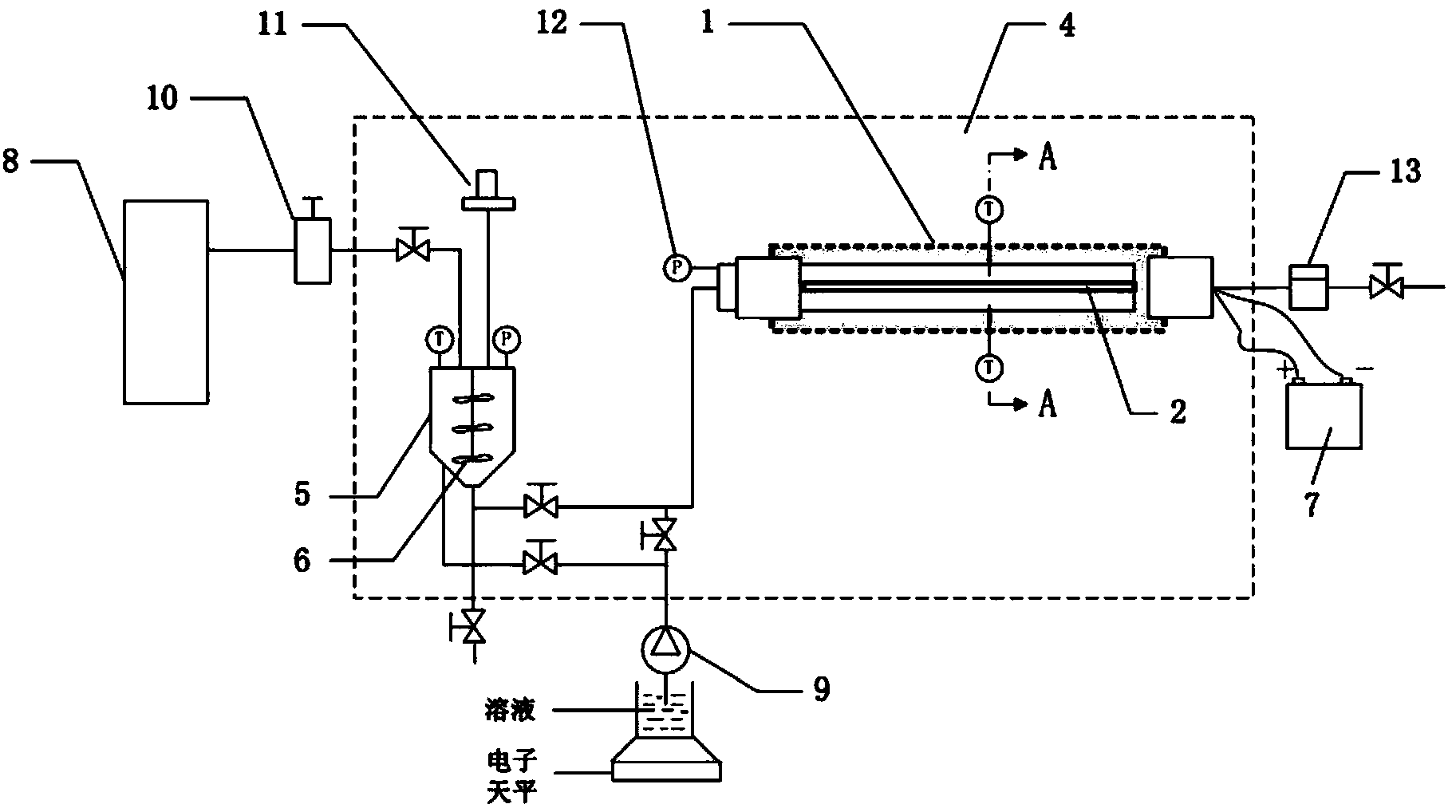

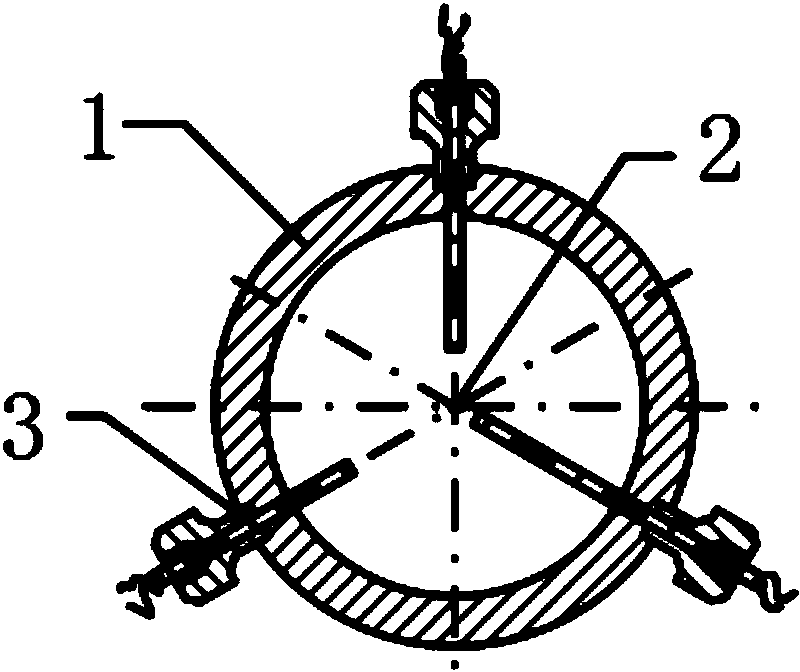

[0031] see figure 1 As shown, a device for measuring the thermal conductivity of natural gas hydrate in porous media, including a gas-liquid supply module for regulating and controlling the gas-liquid content in the high-pressure reactor 1, and generating any required uniform hydrate saturation system , a temperature control module used to provide a constant temperature for the device, the temperature control module is used to control the low temperature environment required for hydrate formation, the high-pressure reactor 1 is placed in a constant temperature water bath 4, and the high-pressure reactor 1 is arranged along the axis There is a resistance wire 2, and the resistance wire 2 is connected to an external stabilized power supply 7, and its core part is the high-pressure reactor 1 in the thermal conductivity measurement module, and the stabilized gas-liquid supply module includes a high-pressure gas source 8, a high-pressure liquid injection pump 9 and a Small gas-liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com