Liquid-phase detection method for casein phosphopeptides in milk

A technology of casein phosphopeptide and phosphopeptide solution, which is applied in the field of liquid phase detection of casein phosphopeptide (CPP), which can solve the problem of inability to meet the needs of convenient, fast, and high-sensitivity detection methods, and the inability to detect trace amounts of casein phosphopeptide in milk and other issues to achieve the effect of removing magazine interference, improving sensitivity and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

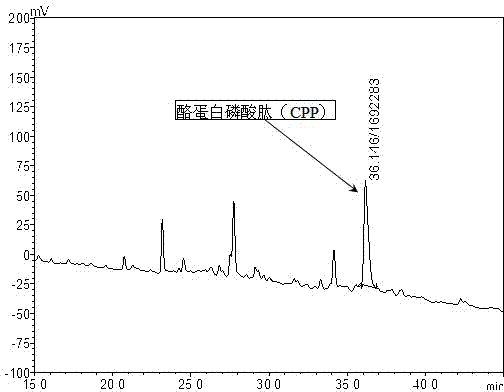

[0040] Embodiment 1: The method for determining the content of casein phosphopeptide (CPP) added in milk provided by the present invention comprises the following steps:

[0041] (1) Put the milk to be tested in a beaker, add a casein phosphopeptide (CPP) standard solution with a concentration of 5 mg / mL, mix well, and add the standard solution to form a 100ppm casein phosphopeptide dispersion solution;

[0042] (2) Deproteinization. The method is to take 5g of pre-prepared casein phosphopeptide dispersion solution in a 50mL plastic centrifuge tube, add 5g of water, mix well, then add 5g of 5‰ trichloroacetic acid, vortex and ultrasonic for 5min, then centrifuge at 4800rpm for 10min, centrifuge Finally, put the centrifuge tube into a water bath at 70°C for 10 minutes, and then centrifuge at 4800 rpm for 10 minutes. Take the supernatant and filter it with filter paper for later use;

[0043] (3) Decalcify through 001×7(732) strongly acidic styrene-based cation exchange resin ...

Embodiment 2

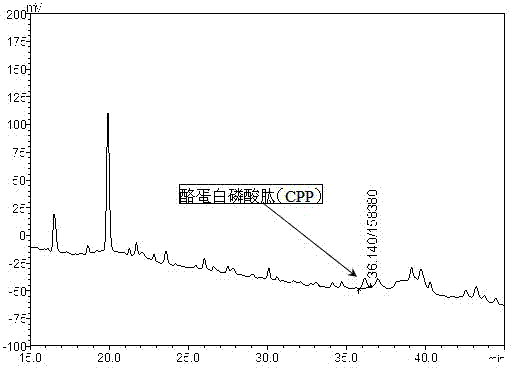

[0048] Embodiment 2: The method for determining the content of casein phosphopeptide (CPP) added in milk provided by the present invention comprises the following steps:

[0049] (1) Put the milk to be tested in a beaker, add a casein phosphopeptide (CPP) standard solution with a concentration of 5 mg / mL, mix well, and add the standard solution to form a 10ppm casein phosphopeptide dispersion solution;

[0050] (2) Deproteinization. The method is to take 10g of the pre-prepared casein phosphopeptide dispersion solution sample in a 50mL plastic centrifuge tube, add 10g of water, mix well, then add 10g of 1‰ trichloroacetic acid, vortex, mix and ultrasonic for 10min, and then centrifuge at 4000rpm for 15min. After centrifugation, put the centrifuge tube into a water bath at 75°C for 15 minutes, and then centrifuge at 4000 rpm for 15 minutes. Take the supernatant and filter it with filter paper for later use;

[0051] (3) Decalcification by Mitsubishi WK60L cation exchange resi...

Embodiment 3

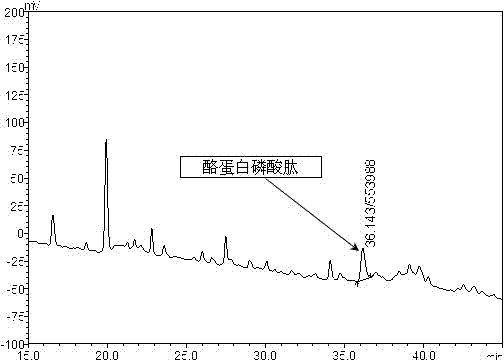

[0056] Embodiment 3: The method for determining the content of casein phosphopeptide (CPP) added in milk provided by the present invention comprises the following steps:

[0057] (1) Put the milk to be tested in a beaker, add casein phosphopeptide (CPP) standard solution with a concentration of 5 mg / mL, mix well, and add the standard solution to form a 50ppm casein phosphopeptide dispersion solution;

[0058] (2) Deproteinization. The method is to take 5g of the pre-prepared sample in a 50mL plastic centrifuge tube, add 5g of water, mix well, then add 2.5mL of chloroform:n-butanol solution (pre-prepared to a volume ratio of 4:1 mixture), vortex and mix well. Sonicate for 15 minutes, then centrifuge at 4800 rpm for 5 minutes, take out the supernatant and repeat the above operation for 3 times. Take the supernatant and filter it with filter paper for later use;

[0059] (3) Decalcification by passing through a Rohm and Haas AMBERJET UP6040 cation exchange resin column. Put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com