A detection device for the easy-cleaning performance of ceramics

A detection device and performance technology, applied in the field of ceramic easy-to-clean performance detection devices, can solve the problems of simple structure, complicated test process, low degree of automation, etc., to ensure the comparability and accuracy of detection, reduce environmental test errors, and low detection cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

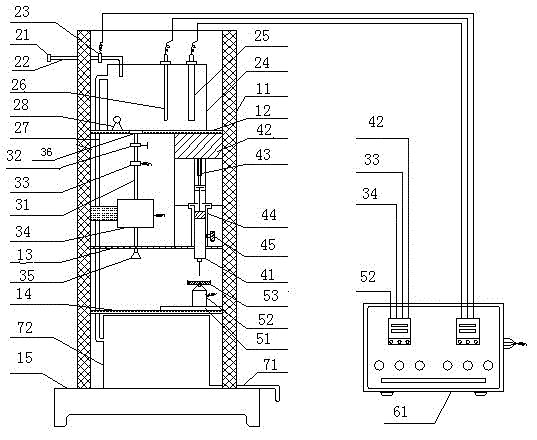

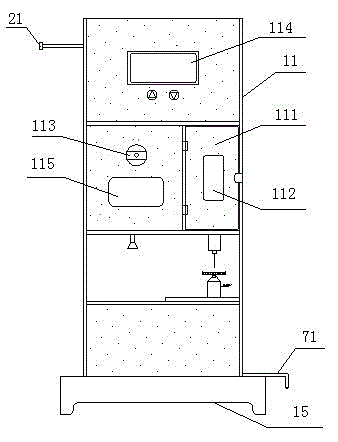

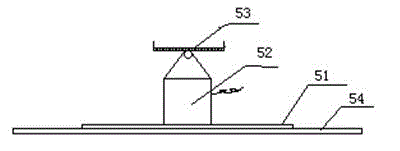

[0035] A specific embodiment of the device of the present invention is given below. The specific embodiment is only a further detailed description and explanation of the ceramic easy-to-clean performance detection device of the present invention, and does not limit the scope of protection of the claims of the present invention.

[0036] The size of the outer box of the embodiment is 300×210×1100 mm, the distance between the upper panel 12 and the top of the outer box 11 is 250 mm, the distance between the upper panel 12 and the middle panel 13 is 300 mm, the distance between the middle panel 13 and the lower panel 14 is 300 mm, and the distance between the lower panel 13 and the lower panel 14 is 300 mm. The distance between the panel and the base is 200mm, and the size of the base is 400×210×50mm.

[0037] The size of the water supply tank is 250×200×200mm.

[0038] The height of the water storage scale line engraved on the upper left side of the upper water tank 24 is 3 / 4 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com