Air-lift rapid circulating type cloth media filter chamber, and filtering method thereof

A filter cloth filter tank, rapid circulation technology, applied in the direction of fixed filter element filter, filtration separation, separation method, etc., can solve the problem that the electric valve is not easy to control and is easily damaged, the sediment cannot be discharged from the tank body, and the installation accuracy is high. problems, to achieve the effect of increased scouring strength, long recoil cycle and less power equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

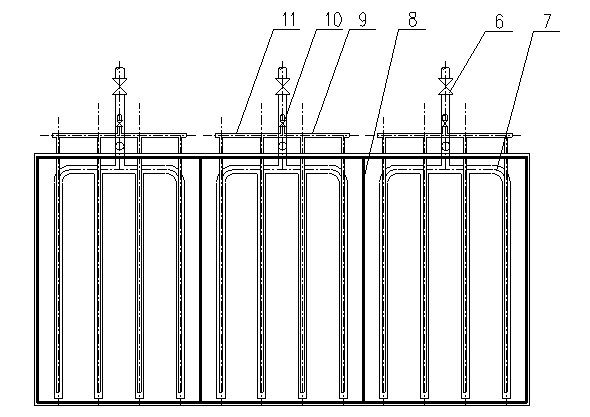

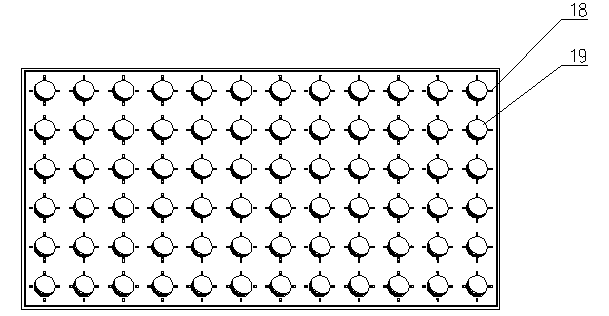

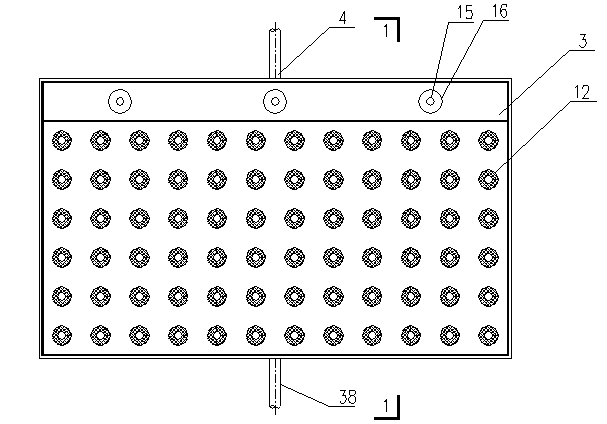

[0021] The marks in the drawings are as follows: water distribution area 1, clear water area 2, water inlet area 3, water inlet main pipe 4, water inlet branch pipe 5, sewage valve 6, drainage main pipe 7, intermediate plate 8, air intake main pipe 9, air intake valve 10. Intake branch pipe 11, filter element 12, air lift accessories 13, stainless steel plate 14, water inlet diversion pipe 15, water inlet distribution pipe 16, floating ball 17, clamp hole 18, accessory hole 19, suspension packing 20, center Tube 21, filter screen 22, rubber gasket 23, filter screen center hole 24, center tube support 25, filter cloth support 26, suspension ring 27, socket baffle tube 28, water stop ring 29, clamp 30, gas collection tube 31, central air intake pipe 32, fixed rib 33, circular plate 34, perforated hole water distribution pipe 35, perforated air distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com