Ammonia-flue gas uniformly mixing device

A flue gas and mixer technology, which is applied in the field of flue gas purification, can solve the problems of uneven flow field downstream of the mixer, large deviation of flue gas velocity, etc., and achieve high energy utilization efficiency, shorten distance, and reduce flow field disturbance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

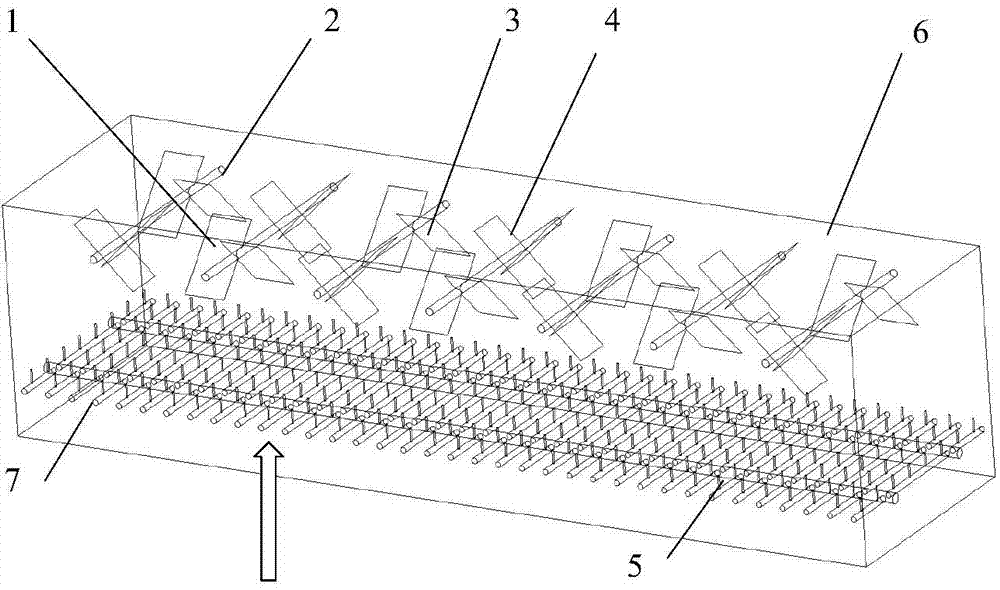

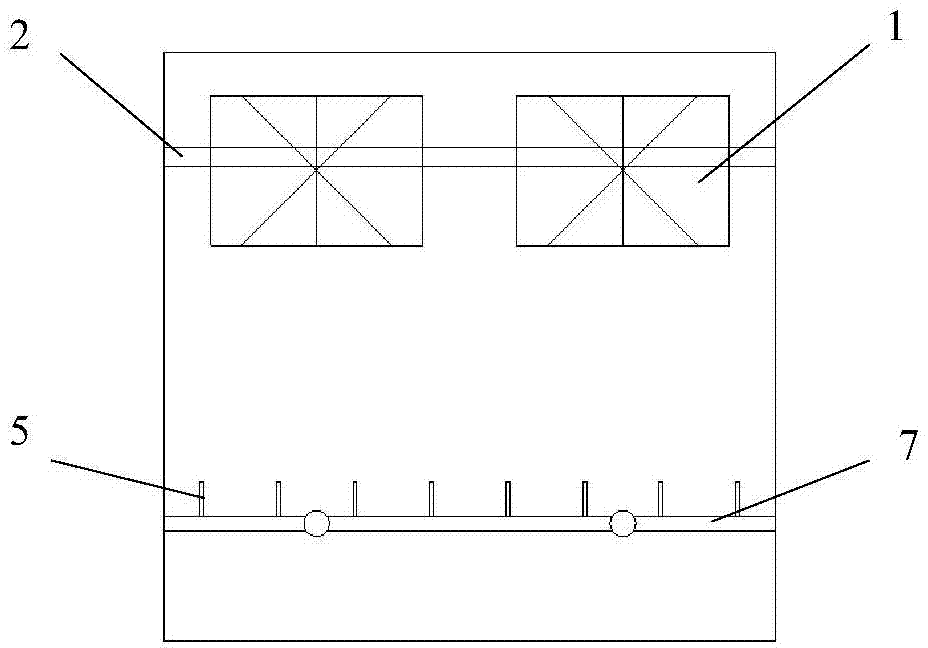

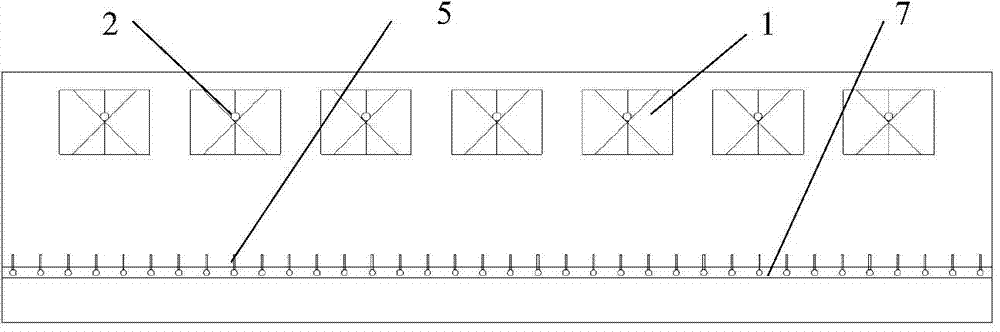

[0031] Such as figure 1 , figure 2 , image 3 As shown, the ammonia-flue gas homogenizing device (hereinafter referred to as the homogenizing device) used in the SCR flue gas denitrification system of a thermal power plant includes 3.5 sets of static mixers 1, each of which consists of 4 mixer units 3 Each mixer unit consists of two intersecting mixing plate blades 4. The mixing plate blade 4 of the mixer unit is fixed in the flue 6 through the support rod 2, the two ends of the support rod are fixed on the side wall of the flue, and two mixer units are fixed on each support rod. figure 1 In the figure, below the homogenizing device is the ammonia injection grid of the SCR flue gas denitrification system, and the ammonia injection grid is composed of the ammonia injection branch pipe 5 and the ammonia injection main pipe 7 connected with the ammonia injection branch pipe. The coverage rate of the static mixer 1 on the horizontal cross-section of the flue is 31.1%. The mixe...

Embodiment 2

[0043] Apply the homogenizing device in the present invention to another thermal power plant SCR flue gas denitrification system, including 3 groups of static mixers, each group of static mixers includes 4 static mixer units, and each static mixer unit includes 2 Composition of mixing plate blades. The fixing method of the blade of the mixing plate is the same as that of Example 1. Due to the short mixing distance between ammonia and flue gas in this SCR system, the static mixer used has a high coverage rate of 59.6% on the horizontal cross-section of the flue, and the mixer unit has an aspect ratio of 1.5:1 The rectangular mixing plate blades are arranged crosswise, and the mixing plate blades form an angle of 60° with the flue gas flow direction. The homogenizing device is arranged 3.0 m above the ammonia injection grid of the SCR flue gas denitrification system.

[0044] Through modeling and numerical simulation calculations, the relative velocity deviation Cv=7.3% at the ...

Embodiment 3

[0047] This homogenizing device is used in the SCR flue gas denitrification system of another thermal power plant, including 2.5 groups of static mixers, each group of static mixers is also composed of 4 static mixing units, and each static mixer unit consists of two length and width Mixing plate blades with a ratio of 2.4:1 are arranged crosswise, and the mixing plate blades form an included angle of 30° with the flue gas flow direction. The installation method is similar to that of Embodiment 1 and Embodiment 2 and fixed in the flue. The coverage rate of the static mixer on the horizontal cross-section of the flue is 21.2%, and the mixer is located 2.0m above the ammonia injection grid of the SCR flue gas denitrification system.

[0048] Through the modeling of the SCR flue gas denitrification system and the simulation calculation results, it can be seen that although the coverage of the static mixer is low and the blade size is relatively small, the relative concentration de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com