MnO2 nanometer composite material and preparation method thereof

A nano-composite material and nano-material technology, applied in the field of MnO2 nano-composite materials and its preparation, can solve problems such as complex structures, achieve high energy density, stable electrochemical cycle performance, and promote the effect of increasing specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention discloses a kind of MnO 2 The preparation method of nanocomposite material, comprises the following steps:

[0030] Disperse manganese-containing nanomaterials in potassium permanganate solution and perform hydrothermal reaction to obtain MnO 2 nanocomposites;

[0031] The manganese-containing nanomaterials are MnOOH nanowires, α-MnO 2 , β-MnO 2 or Mn 3 o 4 .

[0032] According to the invention, the manganese-containing nanometer material is dispersed in the potassium permanganate solution, and hydrothermal reaction occurs with the potassium permanganate solution according to the difference of the manganese-containing material. The manganese-containing material is a MnOOH nanowire, and the MnOOH nanowire reacts with potassium permanganate, and the MnOOH is converted into β-MnO 2 , Potassium permanganate self-decomposes to obtain parallel or staggered sheet-like δ-MnO 2 layer wrapped in the β-MnO 2 peripheral. The mangane...

Embodiment 1

[0040] Disperse 15 mg of MnOOH nanowire template in 40 mL of 0.01 mol / L, pH 3 potassium permanganate solution, and ultrasonically disperse for 10 minutes to obtain a mixed system.

[0041] The mixed system was moved to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and a hydrothermal reaction was carried out at a temperature of 140° C. for 8 hours. The reacted product was washed with water and ethanol, and dried at 60°C to obtain MnO 2 nanocomposites.

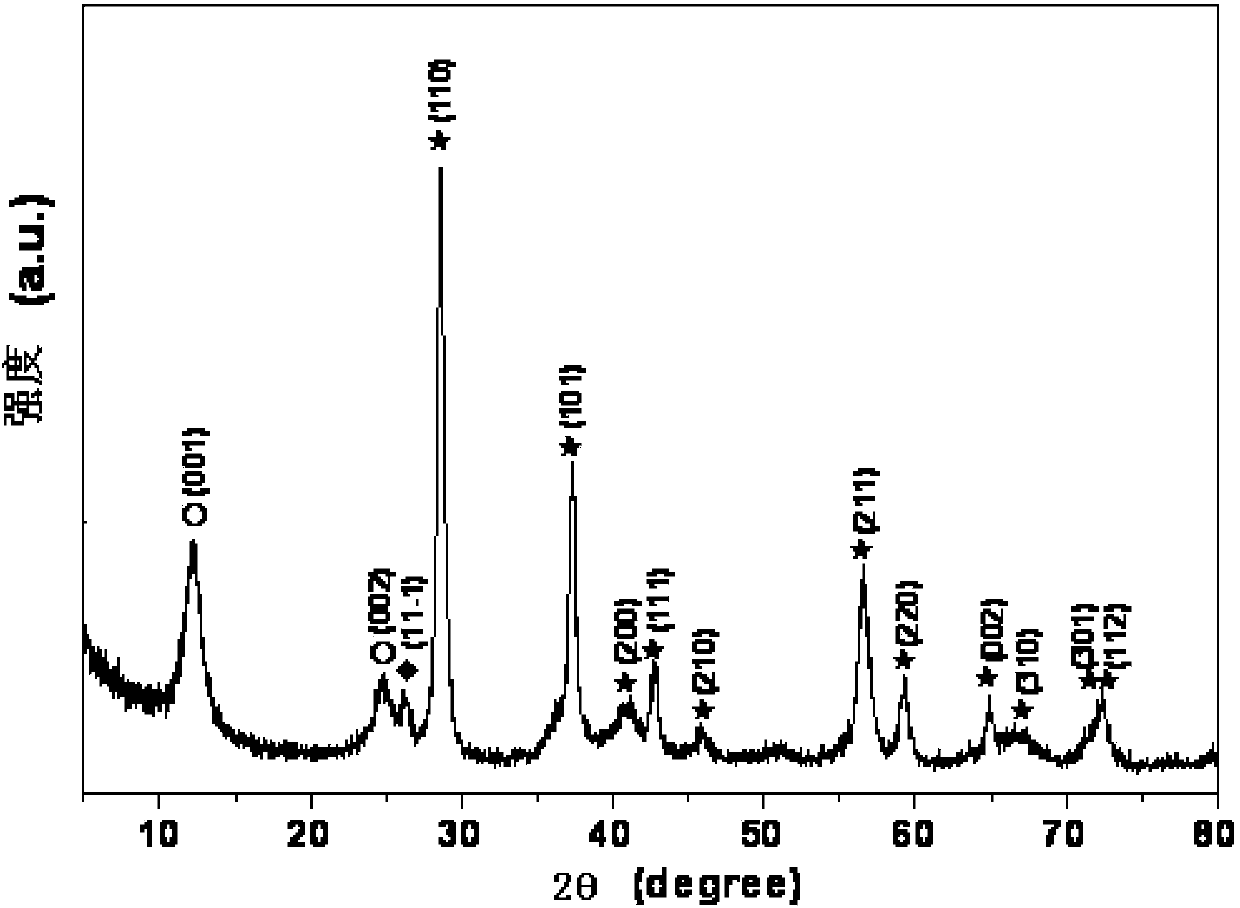

[0042] figure 1 MnO prepared for Example 1 2 XRD patterns of nanocomposites. figure 1 In, O is δ-MnO 2 (JCPDS80-1098), ★ is β-MnO 2 (JCPDS81-2261), ◆ is MnOOH (JCPDS41-1379).

[0043] figure 2 MnO prepared for Example 1 2 SEM images of nanocomposites;

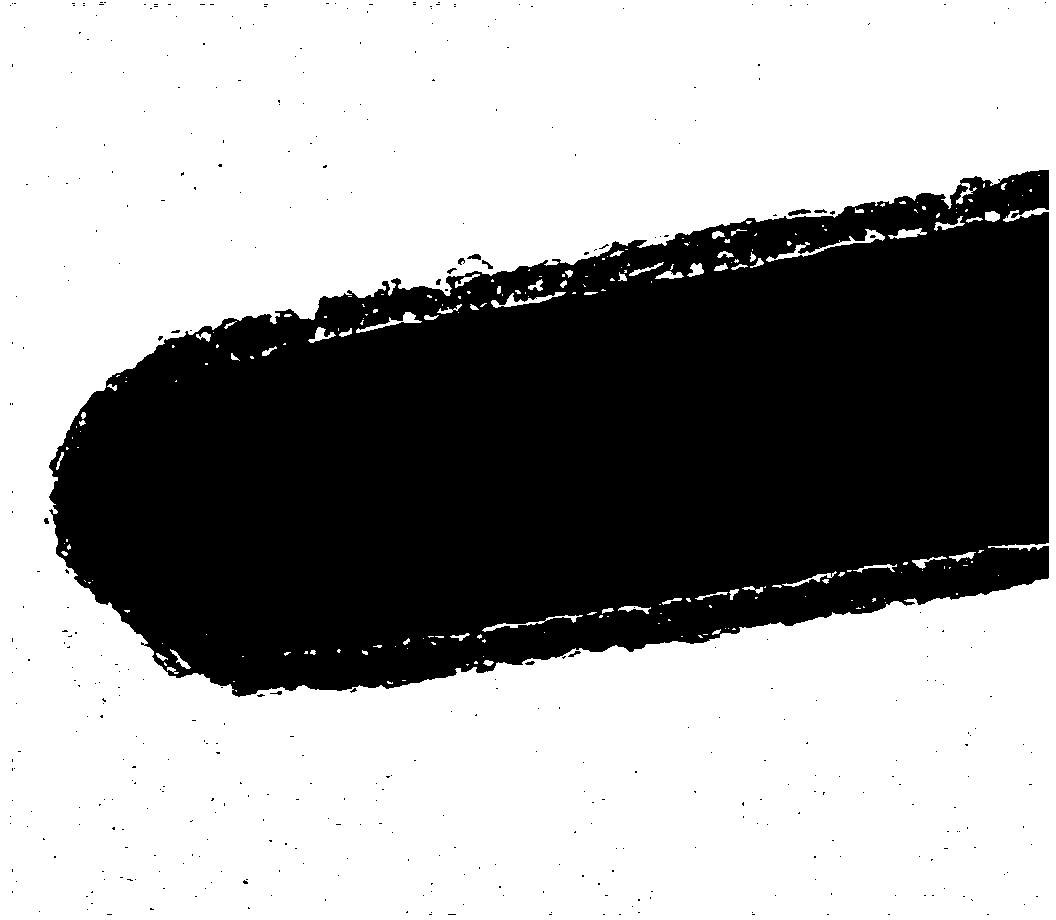

[0044] image 3 MnO prepared for Example 1 2 TEM image of the nanocomposite.

[0045] Depend on Figure 1 ~ Figure 3 It can be seen that the embodiment has prepared MnO 2 nanocomposites.

[0046] Figure 4 MnO prepared for Example 1 2 EBT curves ...

Embodiment 2

[0053] Disperse 20 mg of MnOOH nanowire template in 40 mL of 0.02 mol / L, pH 3 potassium permanganate solution, and ultrasonically disperse for 10 minutes to obtain a mixed system.

[0054] The mixed system was moved to a polytetrafluoroethylene-lined hydrothermal reaction kettle, and a hydrothermal reaction was carried out at a temperature of 140° C. for 8 hours. The reacted product was washed with water and ethanol, and dried at 60°C to obtain MnO 2 nanocomposites.

[0055] Figure 9 MnO prepared for Example 2 2 SEM image of the nanocomposite.

[0056] MnO of the present invention 2 The specific capacitance of the nanocomposite material is 280.6F / g, and after 1000 cycles, it can still maintain 91% of the original capacitance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com