One-step method for preparing grafted polyolefin wax emulsion

A technology for grafting polyolefin and polyolefin wax, applied in the field of modified polyolefin, can solve the problems of side reactions, difficult separation of products, and inability of PP wax to turn yellow and black.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Step 1, solid phase grafting reaction

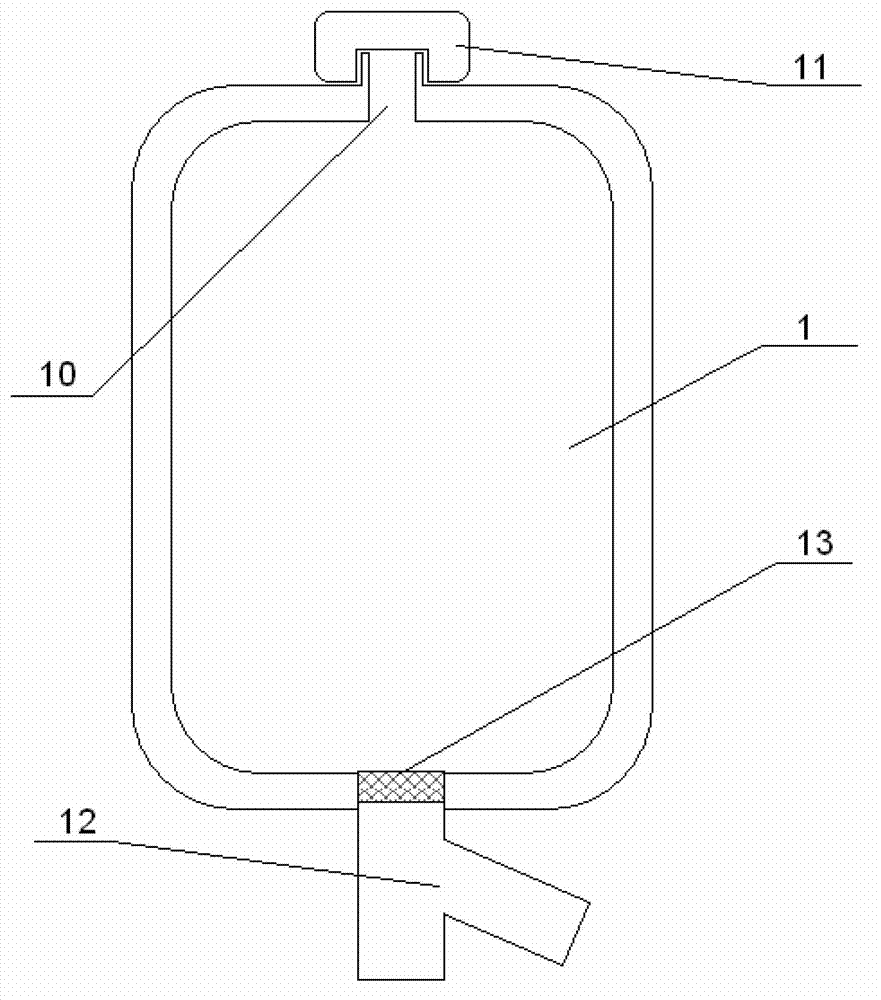

[0064] The reaction kettle used is as figure 1 shown.

[0065] In the autoclave 1 with a high-speed stirrer, 1 kg of polypropylene wax (provided by Klein), 30 g of maleic anhydride, and 15 g of xylene were sequentially added, and the temperature was raised while stirring evenly for 10 minutes to fully mix the raw materials. After adding 20g of the initiator dibenzoyl peroxide (BPO), in order to prevent the sublimation and volatilization of maleic anhydride, the reaction kettle was strictly sealed with a sealing cover 11, and the temperature was continued to rise to 100-130°C, and the reaction was performed at a constant temperature for 1-2 hours.

[0066] Step 2, removal of grafted comonomer and xylene

[0067] After the reaction is finished, cool down to below 40°C, add acetone from the feed port 10 of the reactor, and then fully stir to dissolve free maleic anhydride and a small amount of xylene (playing the role of purify...

Embodiment 2

[0079] Step 1, solid phase grafting reaction

[0080] In an autoclave with a high-speed stirrer, add 1.5kg polypropylene wax (provided by Klein), 50g glycidyl acrylate and 25g xylene in sequence, and stir evenly for 10 minutes while raising the temperature to fully mix the raw materials . After adding 15g of initiator dicumyl peroxide (DCP), continue to heat up to the range of 100-130°C, and react at constant temperature for 1-2 hours.

[0081] Step 2, removal of grafted comonomer and xylene

[0082] After the reaction, cool to below 40°C, add acetone and stir fully to dissolve free glycidyl acrylic acid and a small amount of xylene, and discharge acetone and acrylic acid through the 200-400 mesh filter device installed at the outlet of the reactor. The glycidyl ether grafted polypropylene wax remains in the reactor 1.

[0083] Step 3, emulsification

[0084] After the acetone is fully volatilized, add 300g of emulsifier, 3g of water, 100g of NaOH, and 35g of sodium ...

Embodiment 3

[0087] Step 1, solid phase grafting reaction

[0088] In an autoclave with a high-speed stirrer, add 1.2kg of polypropylene wax (provided by Klein), 43g of methyl methacrylate and 18g of xylene in sequence, and stir evenly for 10 minutes while raising the temperature, so that each raw material is fully mix. After adding 30g initiator dibenzoyl peroxide in batches, continue to heat up to within the range of 100-130°C, and react at constant temperature for 1-2 hours.

[0089] Step 2, removal of grafted comonomer and xylene

[0090] After the reaction is finished, cool to below 40°C, add acetone and stir fully to dissolve free methyl methacrylate and a small amount of xylene, and discharge acetone through the 200-400 mesh filter device added at the outlet of the reactor. The methyl methacrylate grafted polypropylene wax remains in the reactor 1.

[0091] Step 3, emulsification

[0092]After the acetone is fully volatilized, add 330g of emulsifier, 3g of water, 160g of N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com