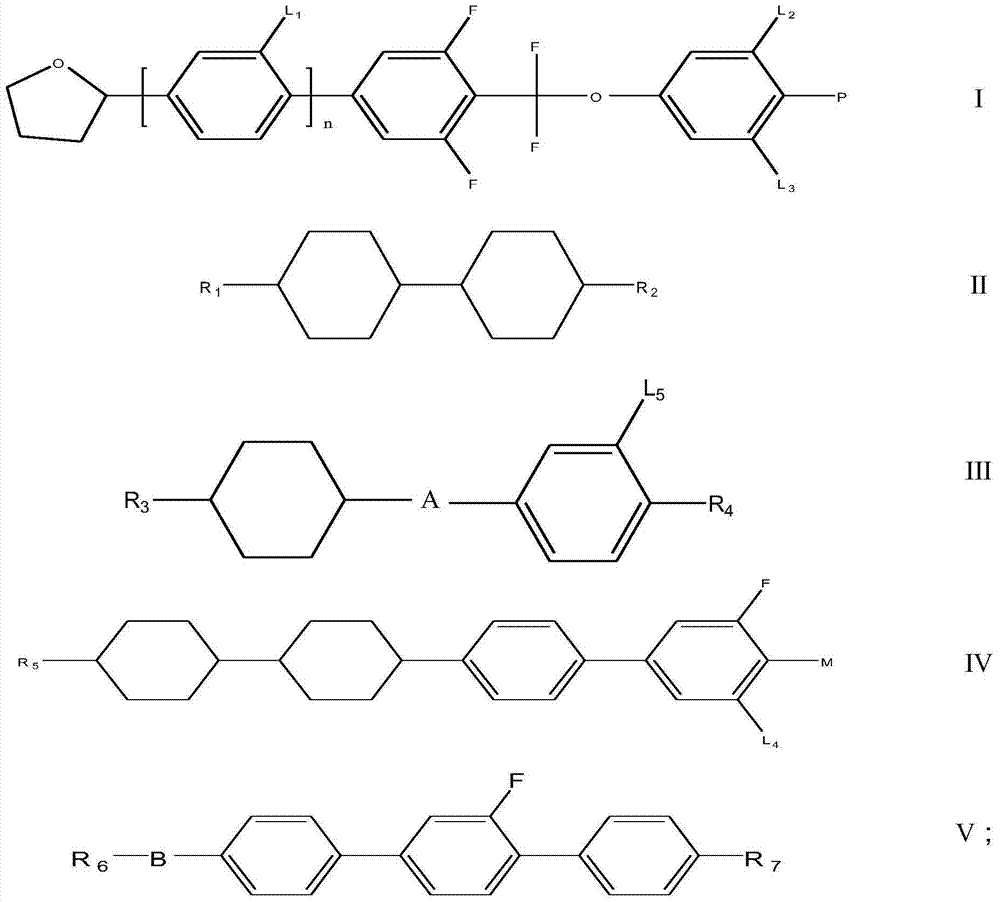

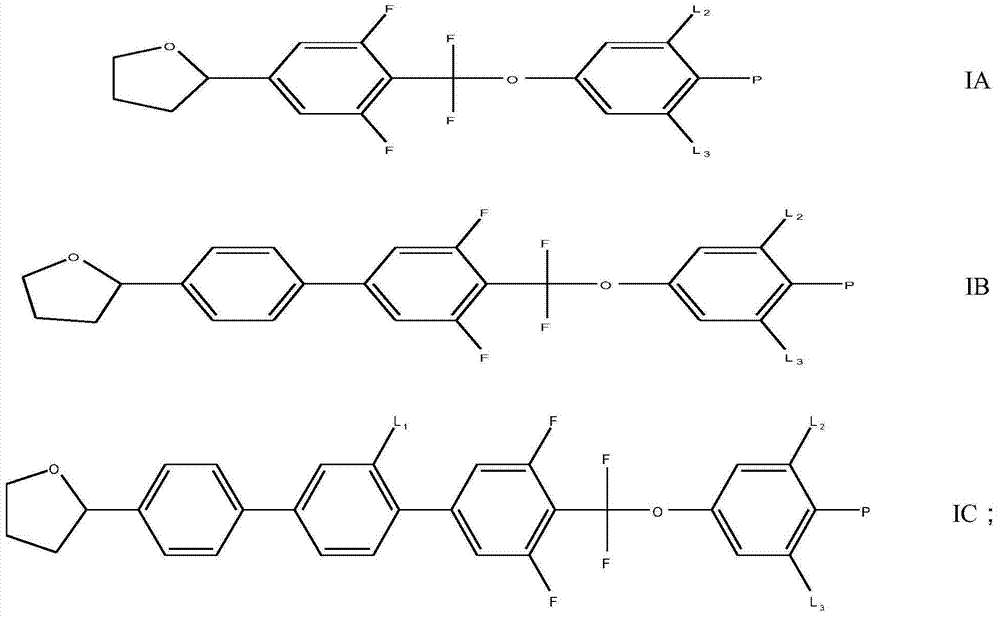

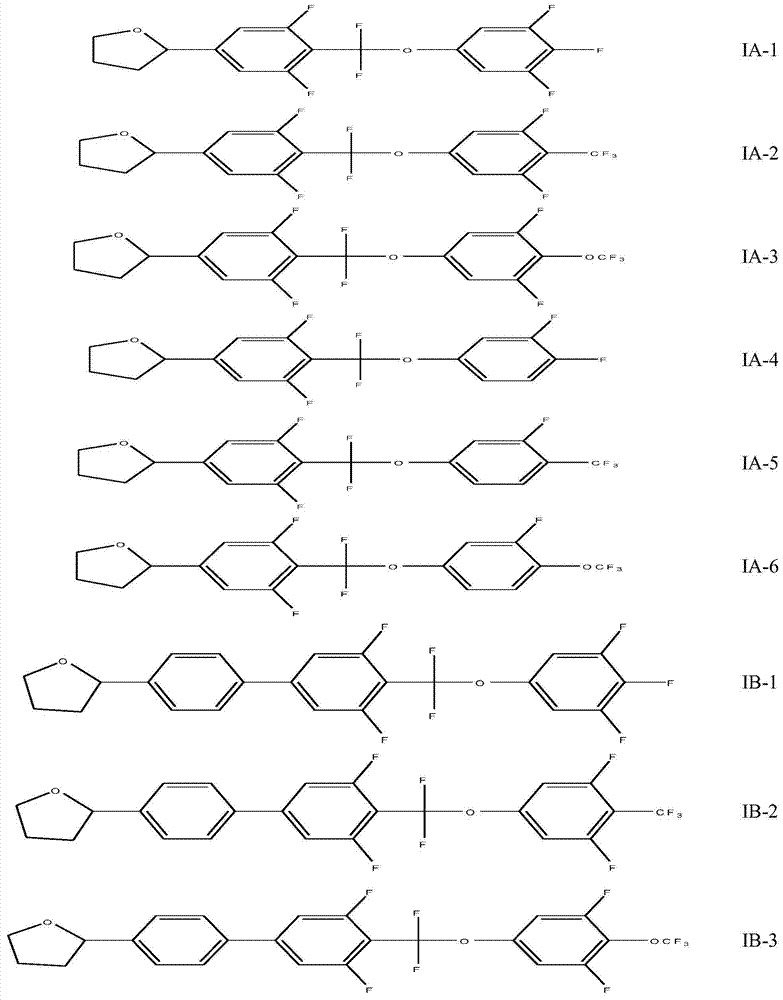

Liquid crystal composition containing tetrahydrofuran compounds and application thereof

A technology of liquid crystal composition and tetrahydrofuran, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve problems such as high viscosity, low resistivity, poor light stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0116] The preparation of liquid crystal composition in the embodiment of the present invention all adopts following method:

[0117] The preparation of uniform liquid crystal adopts the thermal dissolution method commonly used in the industry. First, the liquid crystal compound is weighed by weight percentage with a balance. There is no specific requirement for the order of weighing and adding. Usually, the liquid crystal compound is weighed and mixed in order of melting point from high to low. Heat and stir at 60-100°C to make each component melt evenly, then filter, rotary evaporate, and finally package to obtain the target sample.

[0118] Unless otherwise stated, percentages in this context are by weight and all temperatures are given in degrees Celsius. Also, the following abbreviations are used: Δn is optical anisotropy (20°C), Δε is dielectric constant anisotropy (25°C, 1000Hz); V 10 is the threshold voltage, which is the characteristic voltage when the relative trans...

Embodiment 1

[0132] Take the liquid crystal compound in the following weight percentages, and prepare the liquid crystal composition by the above-mentioned preparation method. The specific proportion and the performance parameters of the obtained liquid crystal composition (not the individual components) are shown in Table 1:

[0133] Table 1: The weight percent of each component in the liquid crystal composition of Example 1 and the performance parameters of the overall composition

[0134] the code

Embodiment 2

[0136] Take the liquid crystal compound in the following weight percentages, and prepare the liquid crystal composition by the above-mentioned preparation method. The specific proportion and the performance parameters of the obtained liquid crystal composition (not the individual components) are shown in Table 2:

[0137] Table 2: The weight percent of each component in the liquid crystal composition of Example 2 and the performance parameters of the overall composition

[0138] the code

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com