Chalcopyrite alkali-smelting pretreatment-low-temperature pressure leaching process

A technology of pressure leaching and pretreatment, applied in the direction of improving process efficiency, can solve the problem of high total pressure, and achieve the effect of solving the problem of leaching and passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

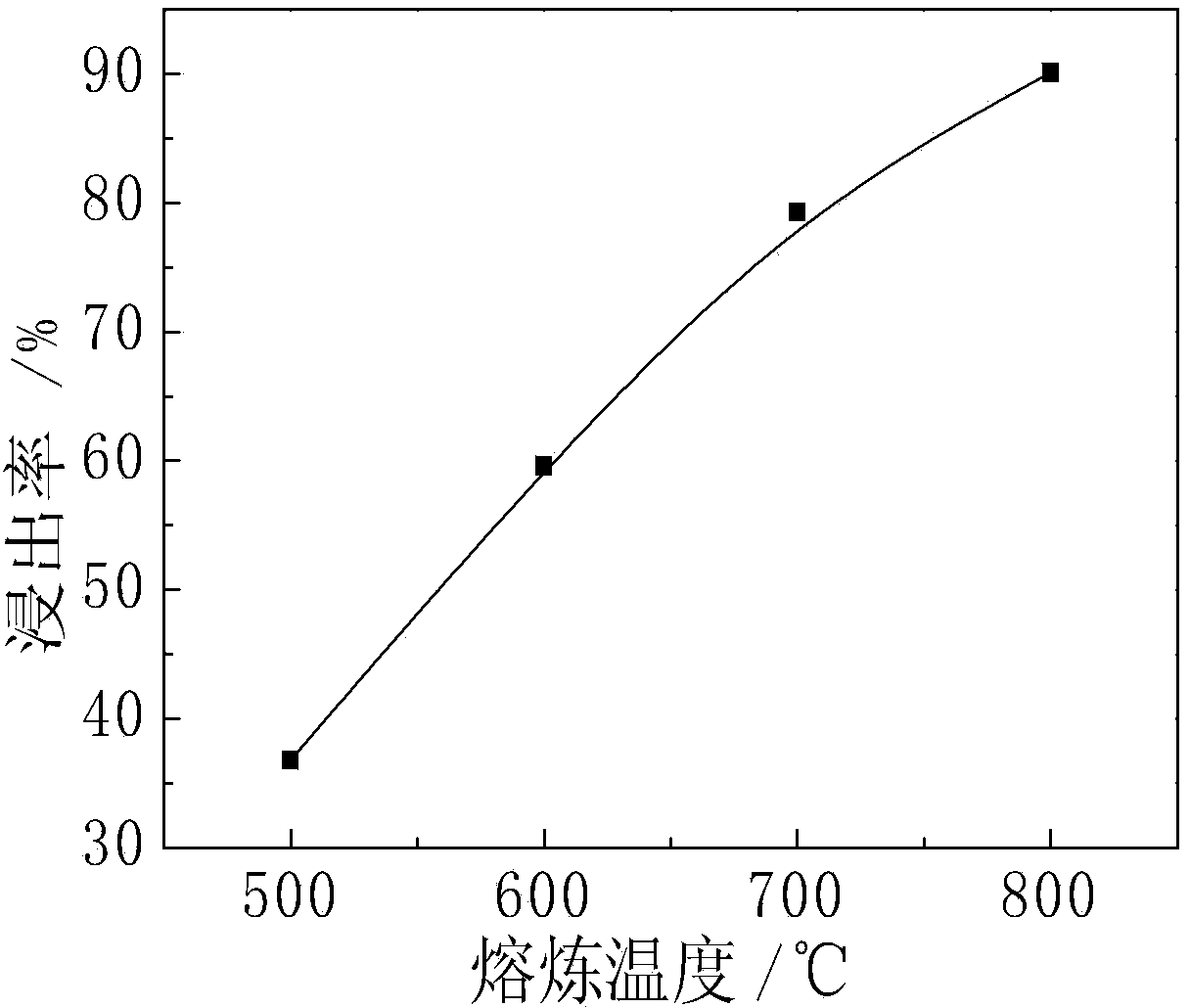

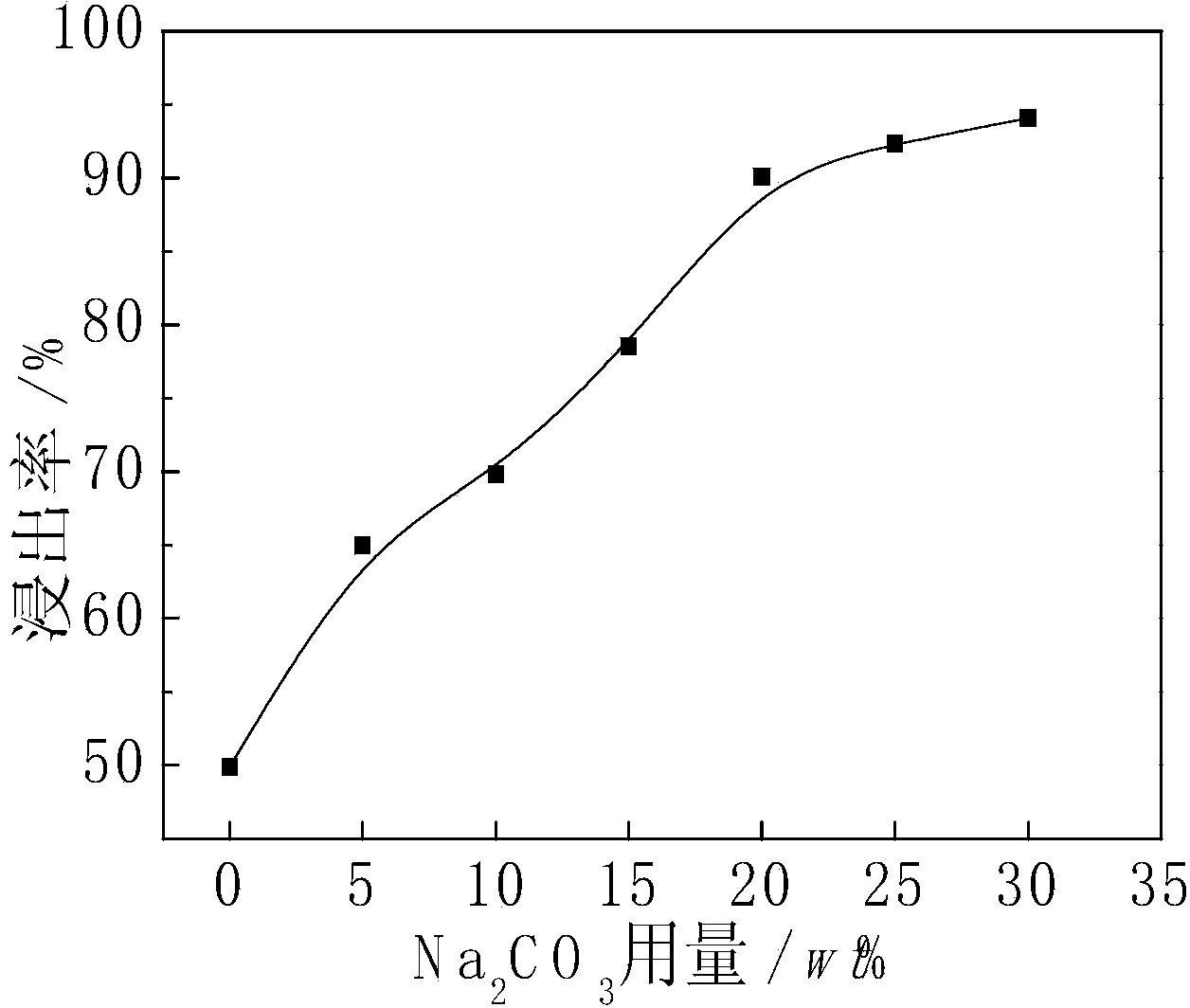

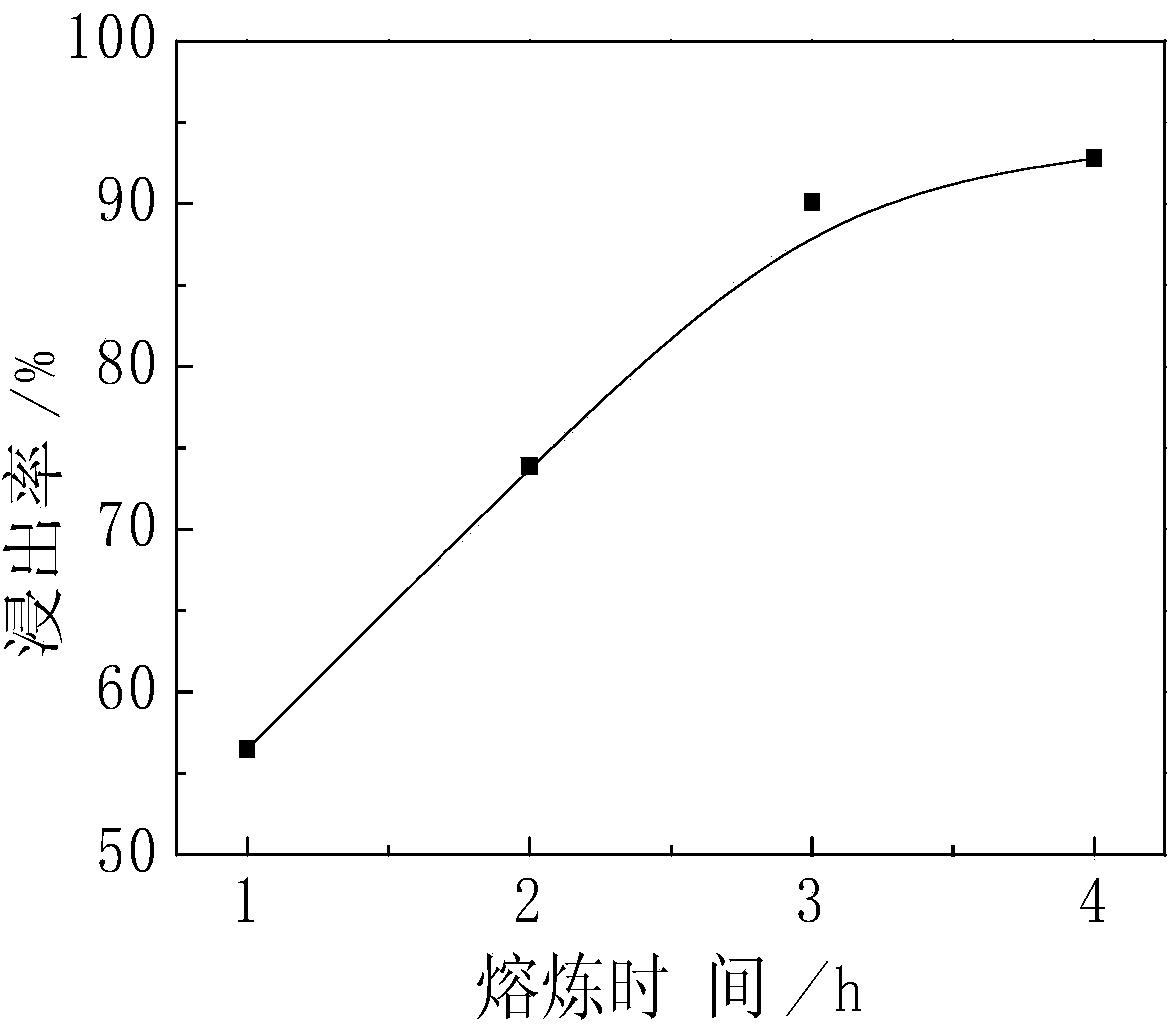

[0060] Chalcopyrite was exposed to Na under the protection of nitrogen 2 CO 3 Melting pretreatment, Na 2 CO 3 The dosage is 5% of the concentrate weight, the smelting temperature is 500°C, and the smelting time is 1.0h. In this process, no volatilization loss of sulfur is seen, and no SO is produced 2 and other harmful gases.

[0061] In the pressure leaching process, the leaching temperature is 110°C, the leaching time is 3.0h, the oxygen partial pressure is 0.6MPa, the initial sulfuric acid concentration is 1.6mol / L, the liquid-solid ratio mL / g is 5 / 1, and the stirring speed is 550r / min. Under the above leaching conditions, the copper leaching rate was 47.58%.

Embodiment 2

[0063] Chalcopyrite was exposed to Na under the protection of nitrogen 2 CO 3 Melting pretreatment, Na 2 CO 3 The dosage is 30% of the concentrate weight, the smelting temperature is 800°C, and the smelting time is 3.0h. In this process, no volatilization loss of sulfur is seen, and no SO is produced 2 and other harmful gases.

[0064] In the pressure leaching process, the leaching temperature is 110°C, the leaching time is 3.0h, the oxygen partial pressure is 0.6MPa, the initial sulfuric acid concentration is 1.6mol / L, the liquid-solid ratio mL / g is 5 / 1, and the stirring speed is 550r / min. Under the above leaching conditions, the copper leaching rate was 94.09%.

Embodiment 3

[0066] Chalcopyrite was exposed to Na under the protection of nitrogen 2 CO 3 Melting pretreatment, Na 2 CO 3The dosage is 20% of the concentrate weight, the smelting temperature is 800°C, and the smelting time is 3.0h. In this process, no volatilization loss of sulfur is seen, and no SO is produced 2 and other harmful gases.

[0067] In the pressure leaching process, the leaching temperature is 80°C, the leaching time is 1.0h, the oxygen partial pressure is 0.2MPa, the initial sulfuric acid concentration is 1.0mol / L, the liquid-solid ratio mL / g is 5 / 1, and the stirring speed is 550r / min. Under the above leaching conditions, the copper leaching rate was 42.34%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com