Spray condensation, high temperature water source heat pump combined with flue gas waste heat recovery device

A water source heat pump and recovery device technology, applied in heat recovery systems, air heaters, fluid heaters, etc., can solve the problem of low heat exchange efficiency and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

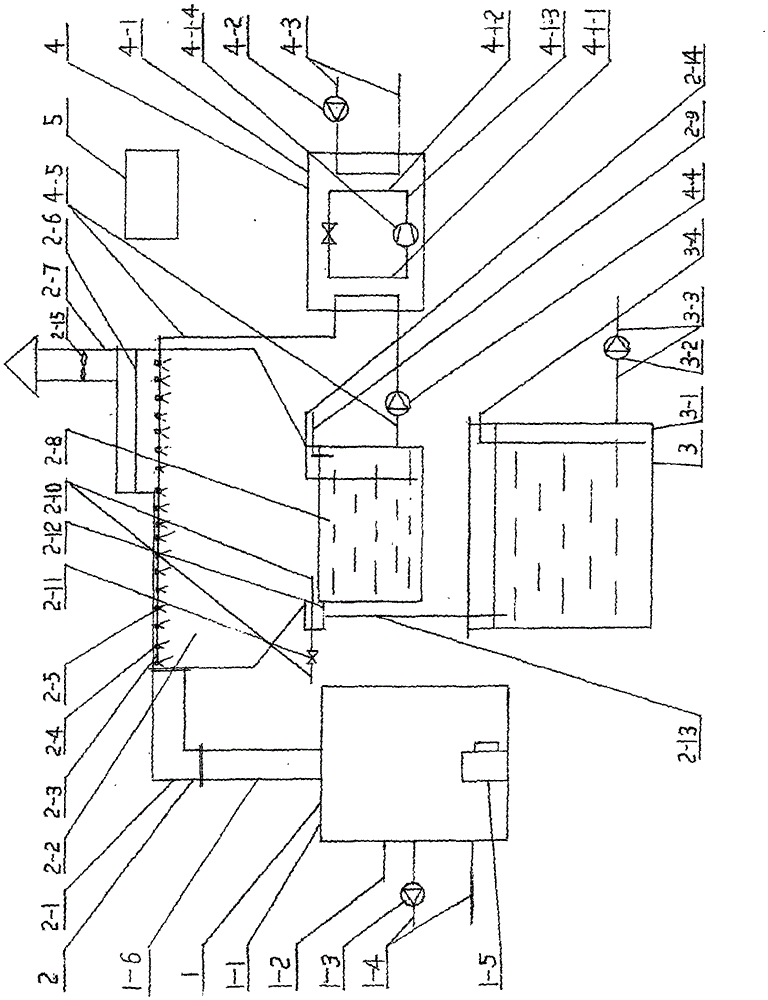

[0018] from figure 1 It can be seen from the figure that this spray condensation, high temperature water source heat pump combined flue gas waste heat recovery device includes five parts: gas boiler system 1, flue gas condensation system 2, water storage system 3, high temperature water source heat pump system 4, and electric control cabinet 5. The gas boiler system 1 is connected with the flue gas inlet pipe 2-1 in the flue gas condensing system 2 . The flue gas condensation system 2 is connected with the water storage system 3 through the overflow pipe 2-13. The flue gas condensation system 2 is connected with the high-temperature water source heat pump system 4 through the water collection tank 2-8 and the internal circulation pipe 4-5. Electric control cabinet 5 is connected with external network water supply pump 1-3, high temperature water sourc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap