Single-compression twin-supercharging double-expansion high-purity nitrogen preparing device

A double-expansion, high-purity nitrogen technology, used in refrigeration, liquefaction, liquefaction, solidification, etc., can solve the problems of high energy consumption of air separation equipment that cannot meet the needs of users, inflexible equipment adjustment and solidification, and waste of excess emptying. The effect of considerable benefits, maximizing economic benefits and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

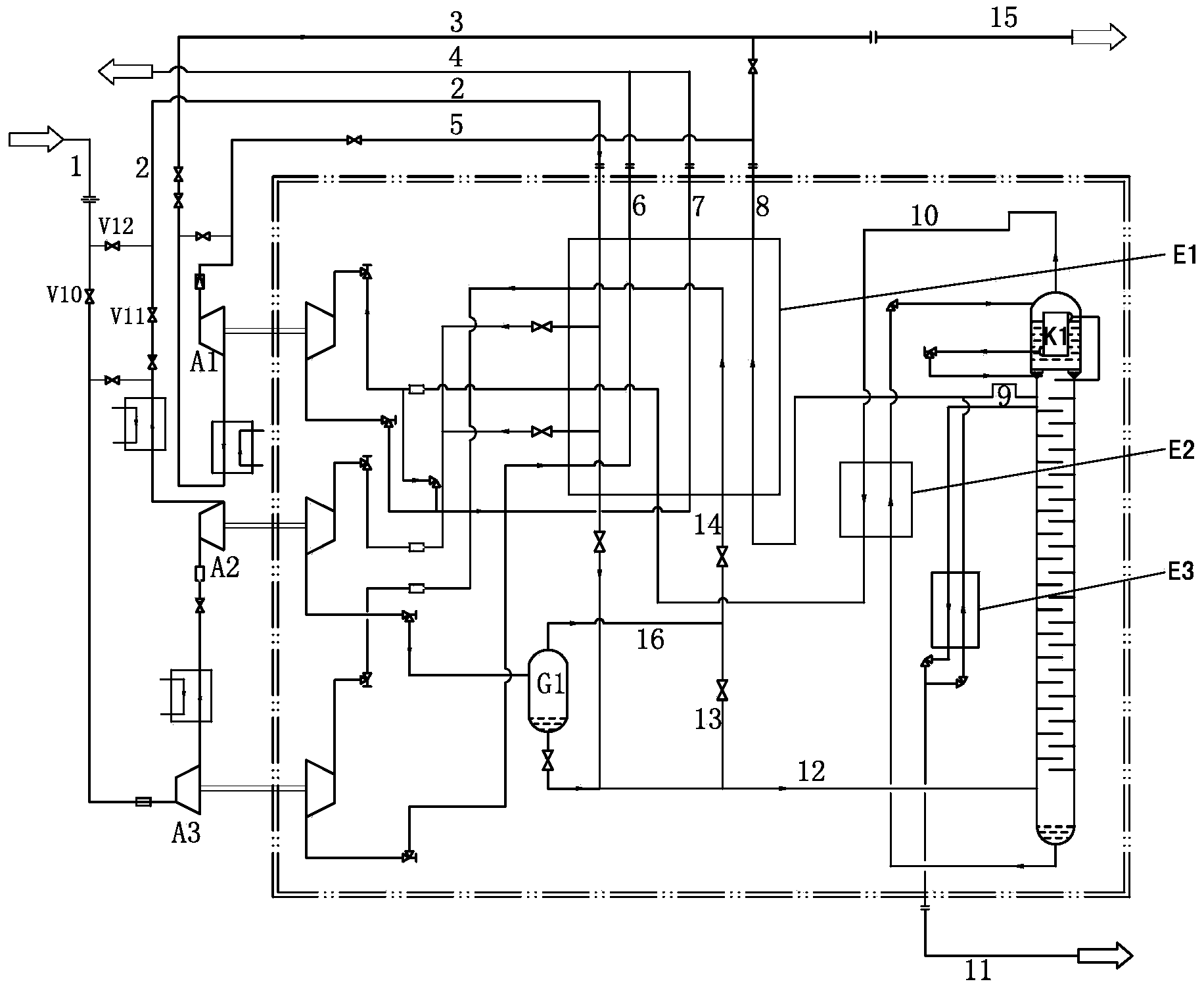

[0017] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 :

[0018] Single-compression double-pressurization double-expansion high-purity nitrogen production device, including rectification tower C1 connected by pipes, condensing evaporator K1, booster turbo expander, main heat exchanger E1, liquid-air subcooler E2, nitrogen Subcooler E3, inlet and outlet pipelines 5 and 2 of supercharger A1 are provided with inlet valve V1 and outlet valve V2, nitrogen and liquid nitrogen are provided with pressure regulating valve V3 on pipeline 8 of distillation column K1, and the booster The turbo-expander is coaxially connected supercharger and expander (A1 and ET1, A2 and ET2, A3 and ET3), part of the purified air is passed to the rectification column C1 through pipelines 1 and 2 or through the supercharger A2 and A3 pass to rectification tower C1, and another part of purified air is sent to expanders E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com