Large-area friction generator and preparation method thereof

A generator and large-area technology, applied in the direction of friction generators, etc., can solve the problems of complex manufacturing process, low practicability, and high cost, and achieve the effects of large area, improved surface roughness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

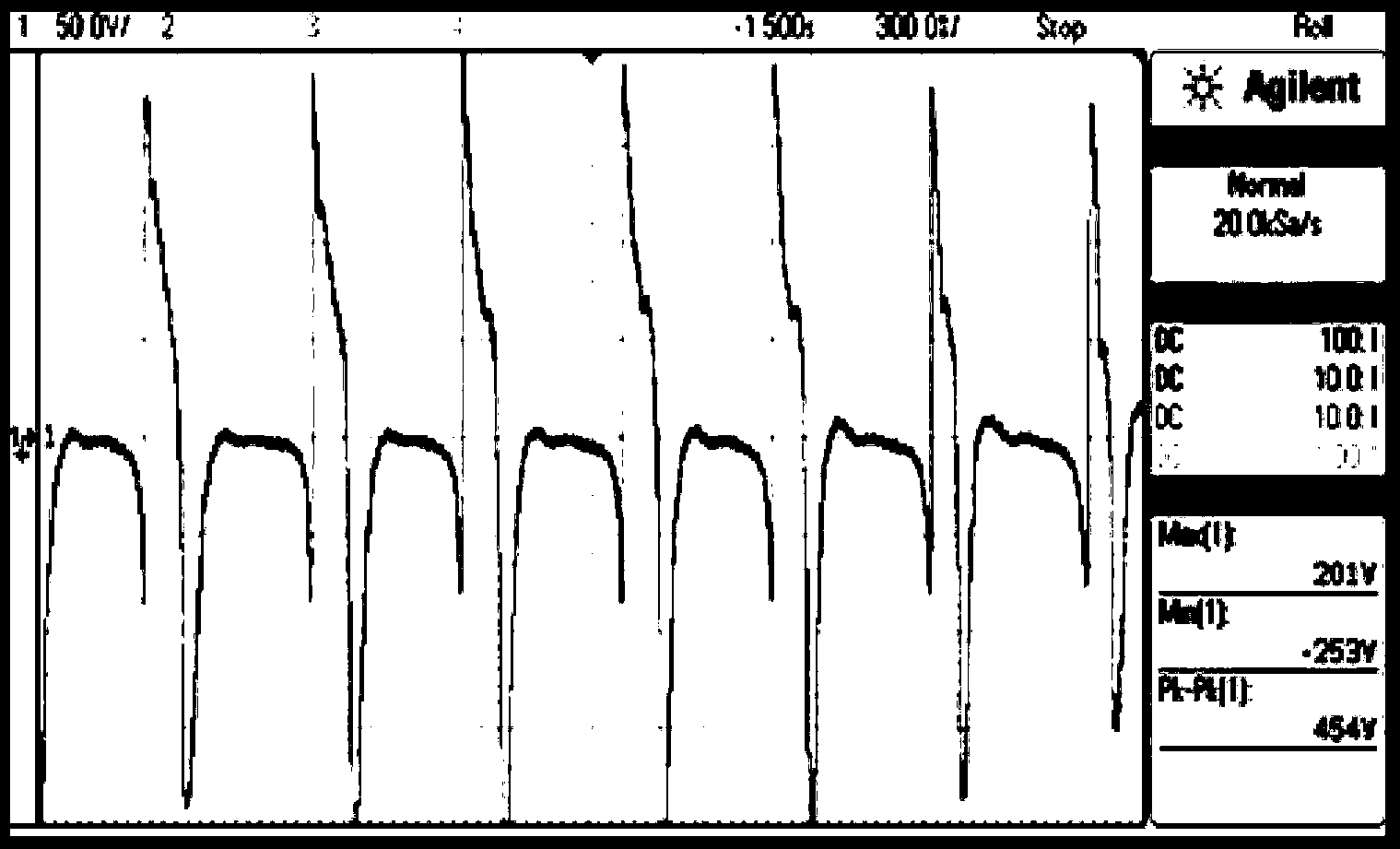

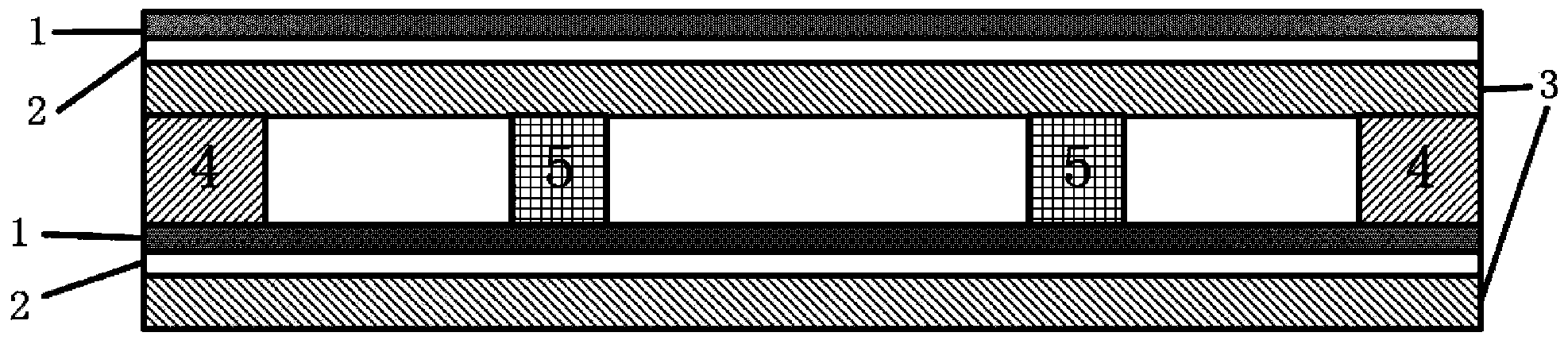

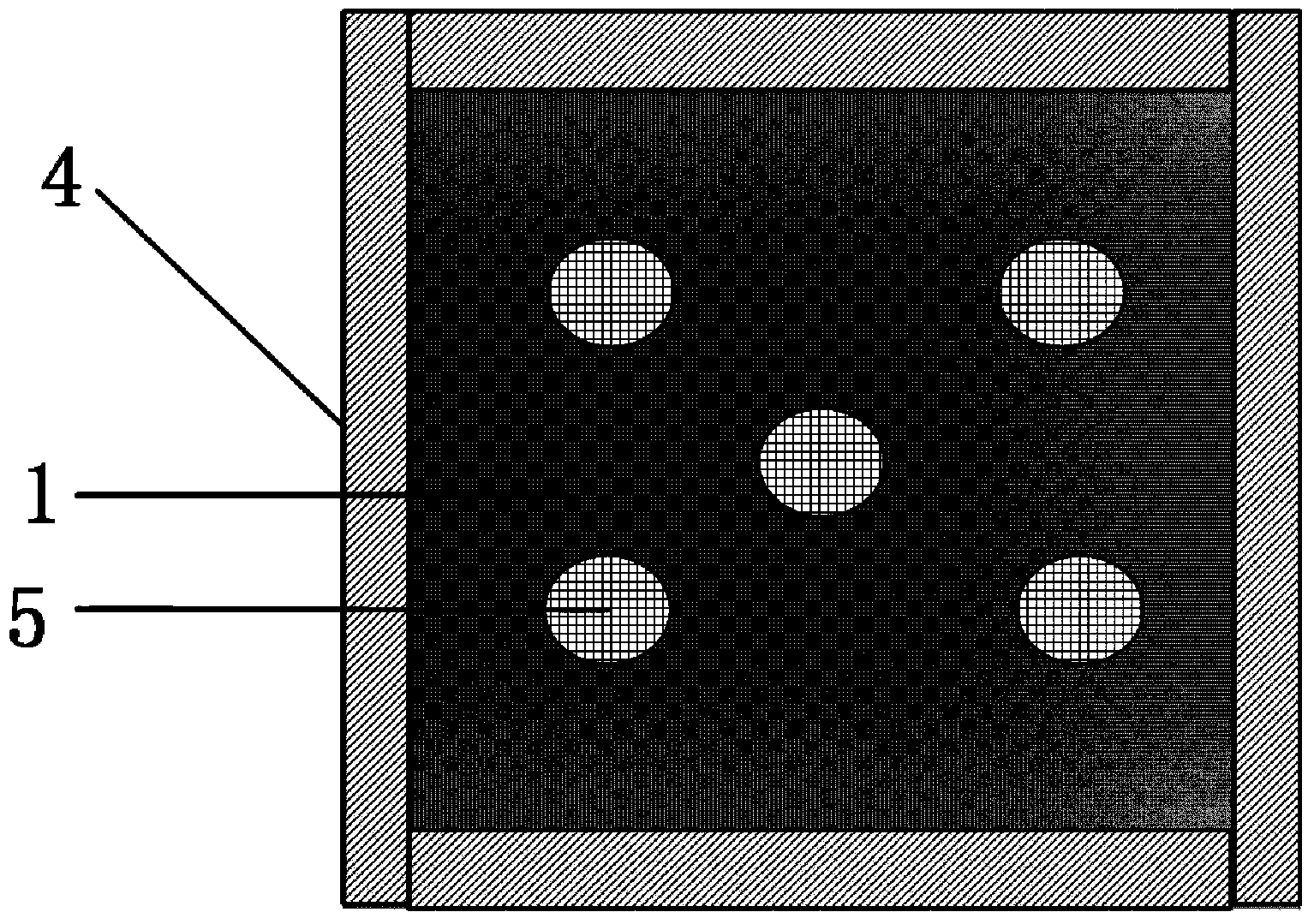

[0039] Attached below Figure 1-4 Example 1 of the specific steps of the frictional power generation floor provided by the present invention and its preparation method is described.

[0040] refer to figure 1 , figure 1 It is a schematic diagram of the structure of the large-area flexible power generation floor in this example. Its structure includes: PE film with frosted structure, conductive electrodes, PET film for support, PVC plastic support frame at the edge, and EVA foam. refer to figure 2 , figure 2 It is a schematic cross-sectional top view structure diagram of this example. refer to image 3 , image 3 It is an array type power generation floor composed of multiple power generation floors. On the one hand, this structure can realize the purpose of large-area power generation floor. On the other hand, through reasonable circuit design, it can be used in the field of security to realize large-area monitoring of human movement without dead ends. And it is used ...

Embodiment 2

[0046] Attached below Figure 4-5 Example 2 of the specific steps of the frictional power generation floor provided by the present invention and its preparation method is described.

[0047] refer to Figure 4 , Figure 4 It is a schematic diagram of the structure of the large-area flexible power generation floor in this example, and its structure includes: PE film with frosted structure, conductive electrodes, PET film for support, smooth PVC film, and EVA foam. refer to Figure 5 , Figure 5 It is a schematic cross-sectional top view structure diagram of this example. This example can also constitute Figure 4The array-type power generation floor composed of multiple power generation floors shown above, on the one hand, this structure can realize the purpose of large-area power generation floor, on the other hand, based on the fully flexible structure, it can be laid under carpets, etc., and through reasonable circuit design, it can be used In the field of security, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com