Tea garden frost-proof method and frost-proof smoke generator

A smoke generator and anti-frost technology, applied in botany equipment and methods, horticulture, applications, etc., can solve the problems of poor anti-freeze effect, air pollution, and anti-freeze smoke generators that have not been reported yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

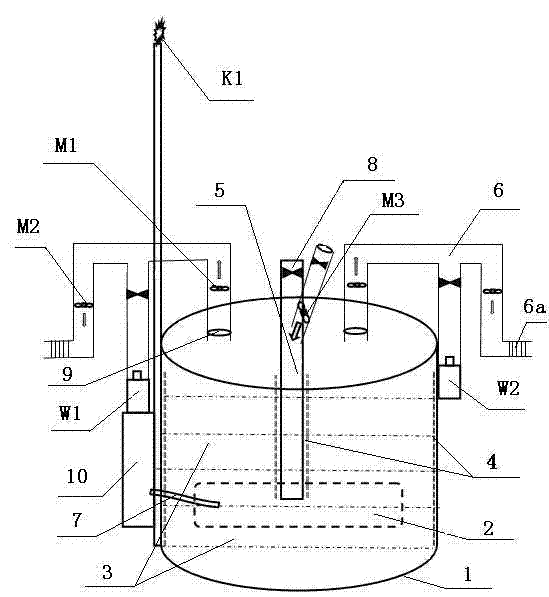

[0020] Example 1: The smoke generator provided by the present invention mainly includes a smoke generating system and an automatic temperature control ignition system, wherein: the smoke generating system includes a barrel body 1 with a barrel cover, the size of the barrel body 1 can be prepared according to different needs, and the inner side of the barrel body 1 There is a smoke guide net 4, a combustion-supporting agent placement area 2, a flame-retardant placement area 3 and a conduit 7 with a lead inside; the smoke-guiding net 4 is located between the flame-retardant placement area and the barrel 1, in order to be more conducive to smoke discharge, guide A smoke guide groove is preferably arranged on the smoke net 4; the combustion-supporting agent placement area 2 and the combustion-resistant agent placement area 3 are filled with combustion-supporting agent and flame-retardant respectively. The combustion-supporting agent placement area 2 is located in the middle and l...

Embodiment 2

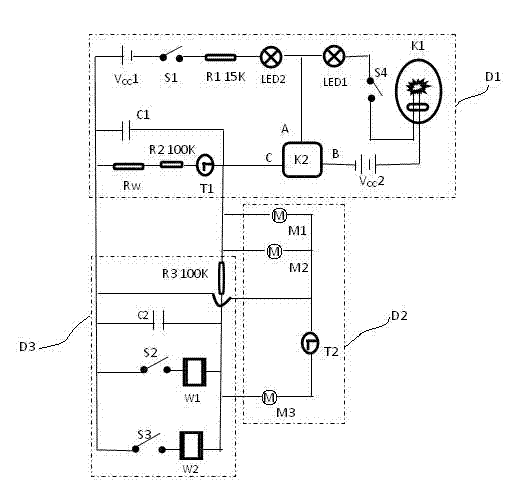

[0027] Example 2: The control circuit of the smoke generator: at least includes an automatic temperature control ignition unit D1 and a combustion-supporting smoke exhaust unit D2. When equipped with an atomization system, it also has an atomization unit D3, wherein: the automatic temperature control ignition unit D1 is mainly composed of a temperature sensor, an upper The bias current resistance R1, the relay K2 and the ignition heating wire Rw are connected by lines; the control circuit of the smoke generating system is a combustion-supporting smoke exhaust unit D2, which mainly consists of a smoke intake and exhaust fan M1 and a smoke exhaust fan M2 connected in parallel with it, and a combustion-supporting fan M3 and a timer T2 connected in series with it; the control circuit of the atomization system is an atomization unit D1, which is mainly composed of a voltage-stabilizing capacitor C2 and an atomizer W1 and / or an atomizer W2. Among them: the power supply Vcc1 is 12V ...

Embodiment 3

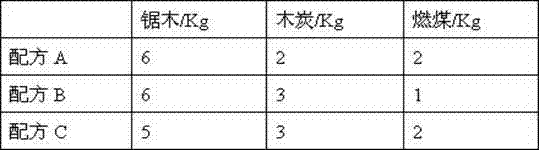

[0030] Example 3: For the filling of smoke generators for frost protection in tea gardens, for example, when the radius of the bottom surface of the barrel 1 is 30cm and the height is 60cm, when placing the fuel, first spread a flame retardant with a thickness of about 10cm within the scope of the smoke guide net 4 at the bottom of the barrel, and then Then, take the center of the barrel as the origin, and spread about 5cm of combustion accelerant (about 500g) in a circle with a diameter of 15cm. Spread 5cm of flame retardant around and on the combustion accelerant, and cover with the lid, so that the combustion ventilation pipe 5 and the smoke guide net 4 just touch the flame retardant. Then, the flame retardant is filled between the smoke guide nets 4 in the barrel 1 through the two smoke outlet pipes. The oxidant placement area is connected to a conduit 7 with a lead wire inside for placing the lead wire for ignition. The lead wire is placed on the side of the oxidant clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com