Cuprous oxide nanowire material and preparation method thereof

A technology of cuprous oxide and nanowires, which is applied in the field of nanomaterials and chemical materials, and can solve problems such as long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 500 ml of sodium hydroxide aqueous solution (concentration: 0.01 mol / liter) to the reaction bottle, then add 0.001 mol of cuprous thiocyanate powder (0.123 g), apply ultrasonic waves for 1 hour, filter, wash, and dry to obtain the oxidized Cuprous nanowire material. The crude yield is greater than 80%.

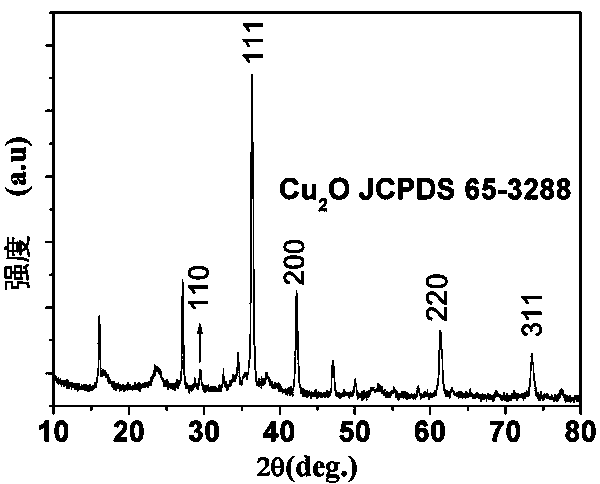

[0020] figure 1 It is the result of XRD analysis, which proves that the main component of the product is cuprous oxide, but also contains a small amount of unreacted cuprous thiocyanate in the product.

[0021] figure 2 is a typical SEM image of cuprous oxide nanowire material, showing random packing of cuprous oxide nanowires. The width of cuprous oxide nanowires is less than 50 nanometers, and the length can reach several micrometers or even longer.

[0022] image 3 The SEM image of the cuprous oxide nanowire material at a higher resolution shows that the width of the nanowire is less than 50 nanometers, and the length has exceeded the imaging range.

Embodiment 2

[0024] Add 500 ml of sodium hydroxide aqueous solution (concentration: 0.02 mol / liter) to the reaction bottle, then add 0.001 mol of cuprous thiocyanate powder (0.123 g), apply ultrasonic waves for 1 hour, filter, wash, and dry to obtain the oxidized Cuprous nanowire material. The crude yield is greater than 75%.

[0025] Figure 4 It is the result of XRD analysis, which proves that the product is cuprous oxide.

[0026] The SEM image of the cuprous oxide nanowire material is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com