Denitrifying-based phosphorus and nitrogen removal process for sequencing batch type two-sludge system

A denitrification phosphorus removal and mud system technology, which is applied in the double mud system denitrification phosphorus removal process and the sequencing batch double mud system denitrification phosphorus removal and nitrogen removal technology field, can solve the problems of complexity and difficulty in wide application, and achieve the system Simple, solve the lack of carbon source, reduce the effect of aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

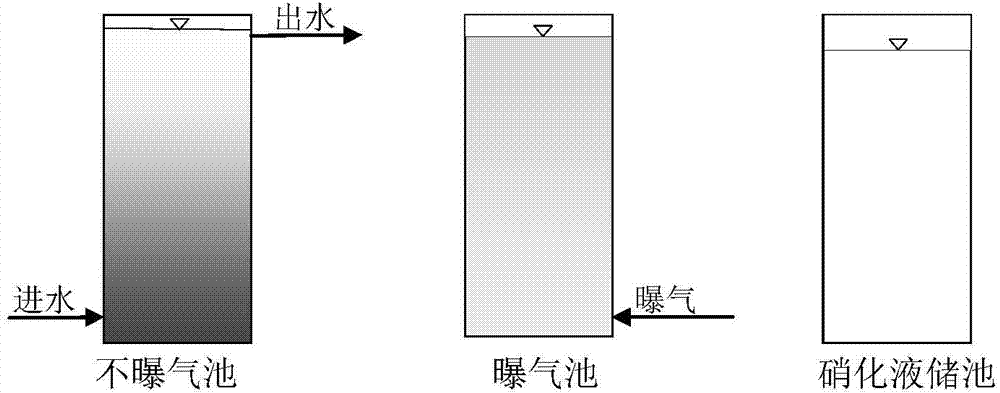

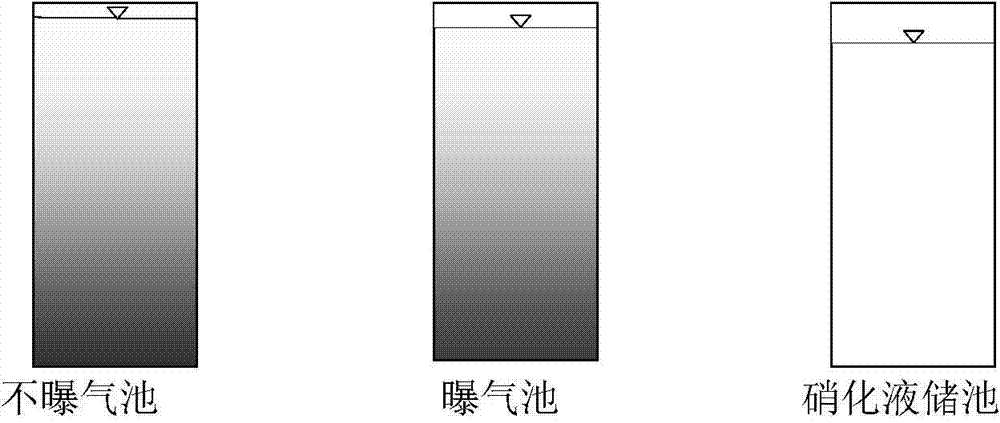

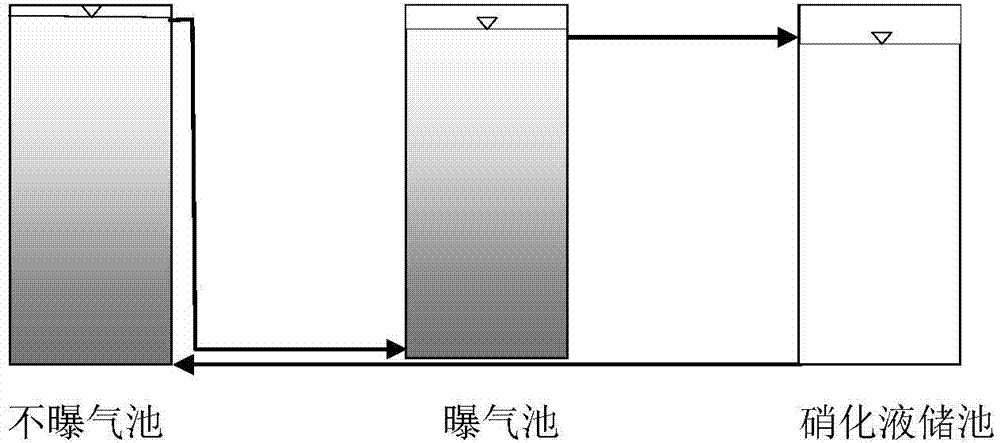

[0025] The denitrification dephosphorization and nitrogen removal process of the double-sludge system of the present invention includes setting a nitrification liquid storage tank, a non-aeration tank and an aeration tank, and any two of the tanks are connected, and the nitrification liquid storage tank, aeration tank Any two pools in the aeration pool and the non-aeration pool are built together or separately, and the nitrifying liquid storage tank, the aeration pool and the non-aeration pool are jointly built or the three pools are built separately; In the tank, the non-aeration tank and the aeration tank or in any one of the tanks, the filler that provides the attachment medium for the growth of the biofilm is added; the sludge is regularly discharged from the nitrifying liquid storage tank, the non-aeration tank, or the aeration tank ;Specific steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com