Change method of externally-installed and bottom-blown air brick of steel ladle

A replacement method and a technology of breathable bricks, which are applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve problems such as increased loss of breathable bricks, difficulty in centering, uneven application of fire mud, etc., to improve work efficiency, Ease of removal and improvement of work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. The working principle of bottom blowing on the outside of the ladle

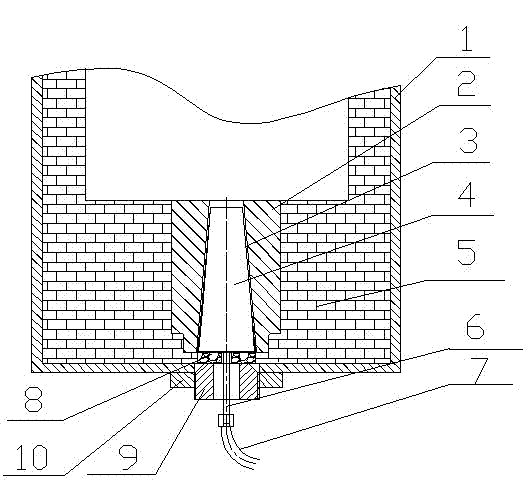

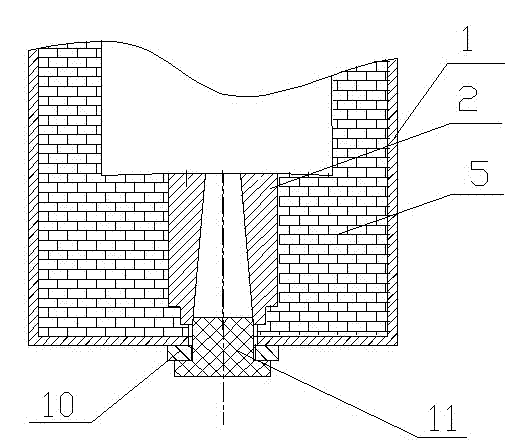

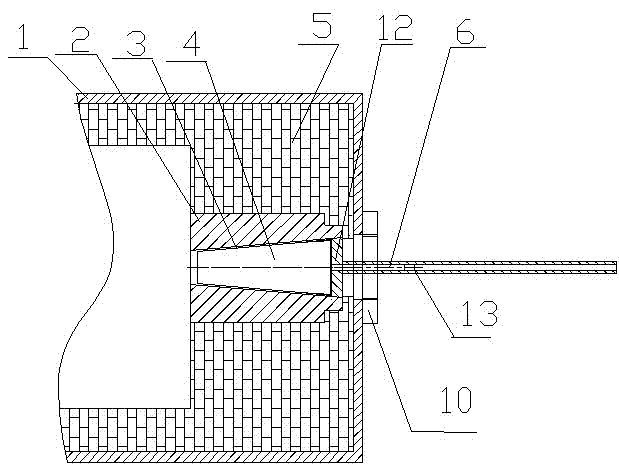

[0029] figure 1 It is a schematic diagram of the working principle of the bottom blowing on the outside of the ladle. The bottom blowing block 2 is installed in the middle of the refractory lining 5 of the ladle, the breathable brick 4 is installed in the seat brick through fire mud, and the adjusting washer 8 is used to adjust the distance between the screw compression mechanism 9 and the breathable brick 4. distance. The screw pressing mechanism 9 is used for pressing and positioning the bottom blowing brick. The pressing mechanism base plate 10 is welded and fixed on the ladle shell 1 , the pressing mechanism base plate 10 is a hollow ring disc, and the inner ring is an internal thread, which cooperates with the screw pressing mechanism 9 . The lower side of the pressing mechanism substrate 10 is required to undergo surface machining, as a reference plane for positioning other devices. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com