Medium-consistency beating device and method using medium-consistency pump for feeding

A thick stock pump and feeding technology, which is applied in the direction of pulp beating method, etc., can solve the problems of expanding pulp flow and pressure pulsation, unstable concentration of medium thick stock, pulp flow and pressure fluctuations, etc., to reduce pulp flow and pressure Pressure pulsation, stable beating quality and effect, stable pressure and flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

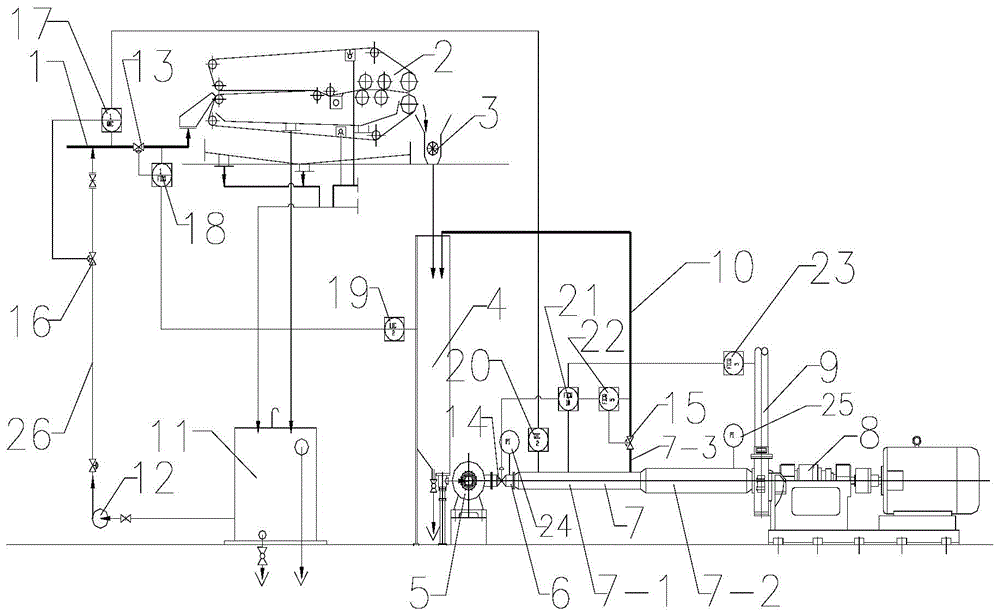

[0024] Such as figure 1As shown, the medium-consistency beating device that adopts medium-consistency pump feeding includes flow control system, medium-consistency double-screen dehydrator 2, crushing screw conveyor 3, standpipe 4, medium-consistency pump 5, buffer pipe 7, medium-consistency Thick disc mill 8, water seal tank 11 and white water pump 12; the feed port of the medium-concentration double-network dehydrator 2 is connected to the slurry feed pipe 1, and its discharge port is connected to the feed port of the crushing screw conveyor 3 The discharge port of the crushing screw conveyor 3 is connected with the feed port of the standpipe 4, and the discharge port of the standpipe 4 is connected with the feed port of the medium-concentrated slurry pump 5; the feed end of the buffer pipe 7 The outlet pipe 6 of the medium-consistency pump is connected to the discharge port of the medium-consistency pump 5, and the discharge end of the buffer pipe 7 is connected to the feed...

Embodiment 2

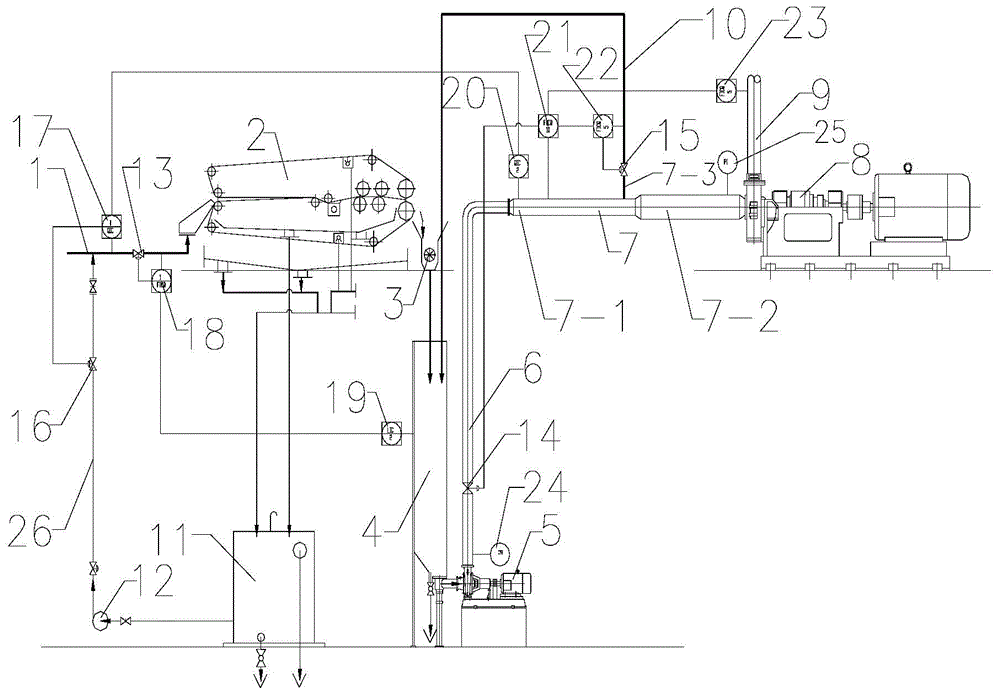

[0041] figure 2 It is a schematic diagram of a medium-consistency beating device using a medium-consistency pump for feeding in this embodiment. Such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that the medium-concentration disc mill 8 of embodiment 2 is installed on the second floor of the workshop, while the medium-concentration disc mill 8 in embodiment 1 is installed on the first floor of the workshop . The medium-consistency slurry pump 5 and the water seal tank 11 are installed on the same plane, while the medium-consistency disc refiner 8 is installed on another higher plane.

[0042] Ben adopts figure 2 The medium-consistency beating method of the medium-consistency pump feed of the device includes the following process:

[0043] 1) Set the beating strength value R0=70kWh / t pulp required for the beating process of the medium-consistency disc refiner, and then calculate and set a passing process based on the rated power W0 accord...

Embodiment 3

[0053] Ben adopts figure 2 The medium-consistency beating method of the medium-consistency pump feeding material of the device includes the following process:

[0054] 1) Set the beating strength value R0=45kWh / t pulp required for the beating process of the medium-consistency disc refiner, and then calculate and set a passing process based on the rated power W0 according to the rated power W0=132kW of the medium-consistency disc refiner. The pulp flow value Q0 of the thickening disc refiner is 2.93t pulp / hour, so that R0=W0 / Q0;

[0055] 2) Through the pulp inlet pipe 1, the pulp slurry with a mass concentration of 4-5% is transported to the medium-concentration double-screen dehydrator 2, and the slurry is dehydrated and concentrated to a set value of 9% mass concentration; The white water regulating valve 16 adds white water to the pulp inlet pipe 1, so that the pulp concentration entering the medium-consistency double-network dehydrator reaches the set value mass concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com