Submarine pipeline trenching machine and trenching method thereof

A technology for submarine pipelines and trenchers, which is applied in the direction of earth movers/shovels, construction, etc., can solve the problems of ineffective soil transportation, reduce the service life of the liquefaction device, increase the wear of the liquefaction device, etc. The speed of silting and firming, reducing wear and improving the degree of liquefaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

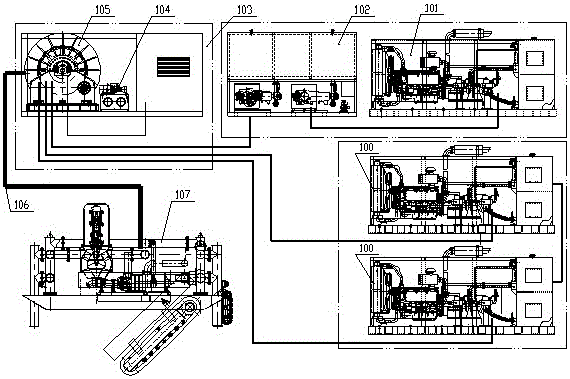

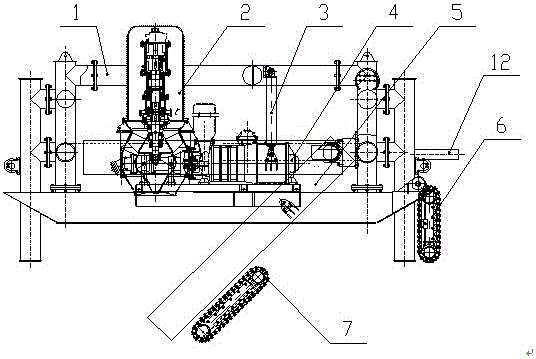

[0034] Refer to attached figure 1 And attached Figure 2-6 , the composition of the submarine pipeline trenching machine of the present invention: pump power unit 100, high-pressure water power unit 101, high-pressure water generating unit 102, control unit 103, umbilical cord winch hydraulic station 104, umbilical cord winch 105, umbilical cord 107, trenching machine body 107. Frame 1, axial flow pump 2, lifting hydraulic cylinder 3, centrifugal pump 4, soil breaking plow 5, upper cutting chain 6, lower cutting chain 7, sliding shoe 8, rear tube protector 9, front tube protector 10, culvert Road cover 11, high-pressure water jet 12.

[0035] Among them, many of the above-mentioned components include two left and right parts, which are as follows: left and right sliding boots, left soil breaking plow, right soil breaking plow, left centrifugal pump, right centrifugal pump, left axial flow pump, right axial flow pump, left high pressure water jet device, right high pressure ...

Embodiment 2

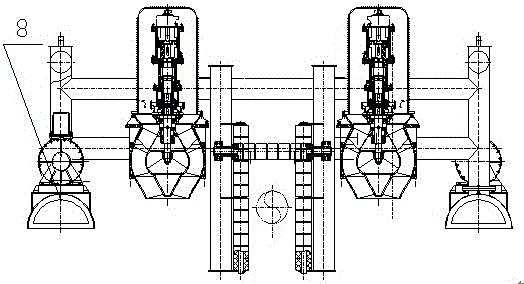

[0040] Refer to attached figure 1 And attached Figure 8-10 , Another kind of scheme of the present invention form is: on the basis of embodiment 1, remove lifting hydraulic cylinder 3, break ground plow 5, upper floor cutting chain 6, lower floor cutting chain 7. Increase the dredging pump 13, and lengthen the front tube protector 10 and the rear tube protector 9 downwards, connect the outlets of the two centrifugal pumps 4 to the left and right conduits of the front tube protector 10, and the left and right conduits of the front tube protector 10 become Nozzle mounting wall. In addition, the suction port of the dredging pump is connected to the left and right conduits of the rear pipe protector 9, and it is used as the suction pipe of the dredging pump 13. In this form, the soil below the pipeline is cut under the action of the pressure water generated by the centrifugal pump 4, and the large flow of water generated by the axial flow pump 2 further sprays it to promote its...

Embodiment 3

[0042] Refer to attached figure 1 And attached Figure 11-13 Another solution of the present invention is: on the basis of embodiment 2, a longer cutting chain 14 is installed on the vertical standpipe of the front tube protector 10, and at the same time, the high-pressure water jet 12 in the inward vertical direction, the The injector nozzles 12 are evenly distributed between themselves and the outlet of the centrifugal pump 4 . At this moment, the dredging pump 13 can be removed.

[0043] The present invention is preparing 4 tool kits for the trencher, namely the axial flow pump 2, the centrifugal pump 4, the high-pressure water ejector 12, the dredging pump 13, and the cutting chain 14. According to different soil strengths, different combinations can be used, so that trenching operations can be effectively implemented, and at the same time, it has better economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com