Compound amylase preparation and its application in starch liquefaction and starch liquefaction method

A technology of compound starch and starch liquefaction, applied in biochemical equipment and methods, enzymes, fermentation, etc., can solve the problems of high viscosity of feed liquid, low benefit, incomplete liquefaction, etc., to increase the rate, increase the degree of liquefaction, Favorable Diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Configuration concentration is the fresh cornstarch feed liquid of 48% by weight, uses the HCl of 1mol / L to adjust pH to 5.6; Takes 20g above-mentioned feed liquids in reaction kettle, adds the compound amylase preparation (S type amylase) of 15U / gDS The enzymatic ratio of amylase and L-type amylase is 20:1), mix evenly, and then heat the oil bath to 115°C for spray liquefaction, and keep it for 8 minutes; 120min.

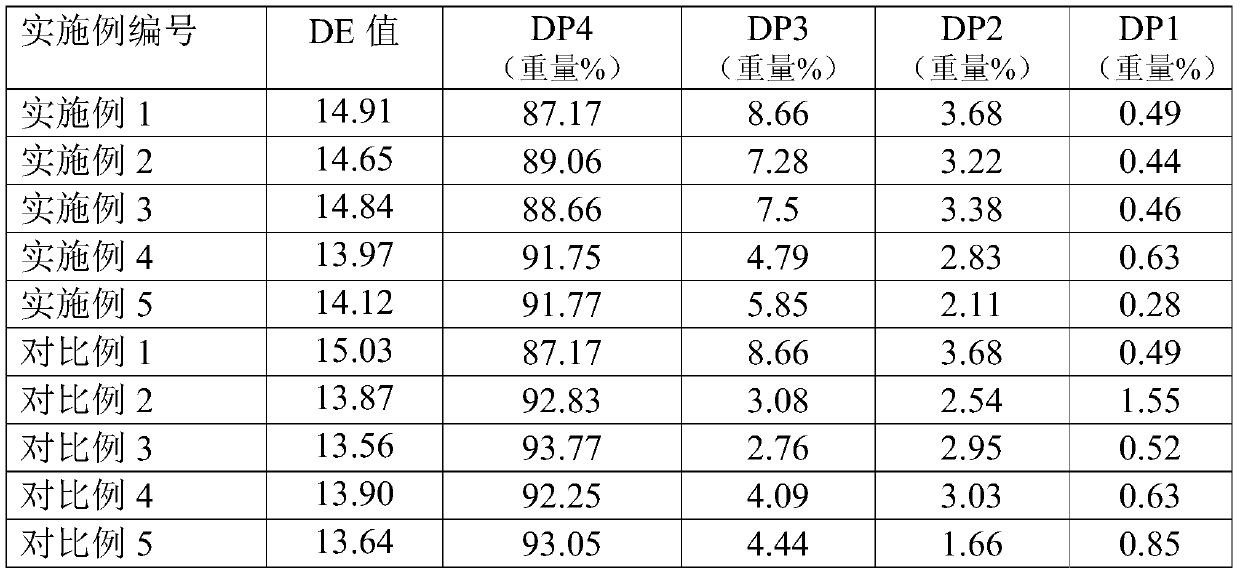

[0048] The DE value and sugar profile distribution (DP) of the reaction product were measured, and the results are shown in Table 2.

[0049] The measured pH value is 5.6, the peak value after mixing the fresh cornstarch feed liquid with a concentration of 48% by weight and the compound amylase preparation of 15U / gDS (the enzyme activity ratio of S-type amylase and L-type amylase is 20:1) Viscosity and final value viscosity, the results are shown in Table 3.

Embodiment 2

[0051] Configuration concentration is the fresh cornstarch feed liquid of 46% by weight, uses the HCl of 1mol / L to adjust pH to 4.5; Takes 20g above-mentioned feed liquids in reaction kettle, adds the compound amylase preparation (S type amylase) of 10U / gDS The enzymatic ratio of amylase and L-type amylase is 15:1), mix evenly, and then heat the oil bath to 110°C for spray liquefaction, and keep it for 5 minutes; 115min.

[0052] The DE value and sugar profile distribution (DP) of the reaction product were measured, and the results are shown in Table 2.

[0053] The measured pH value is 4.5, and the peak value after mixing the fresh corn starch feed liquid with a concentration of 46% by weight and the compound amylase preparation of 15U / gDS (the enzyme activity ratio of S-type amylase and L-type amylase is 15:1) Viscosity and final value viscosity, the results are shown in Table 3.

Embodiment 3

[0055] Configuration concentration is the fresh cornstarch feed liquid of 50% by weight, uses the HCl of 1mol / L to adjust pH to 6; Takes 20g above-mentioned feed liquids in the reactor, adds the compound amylase preparation (S type amylase) of 25U / gDS The enzymatic ratio of amylase and L-type amylase is 25:1), mix evenly, and then heat the oil bath to 120°C for spray liquefaction, and keep it for 10 minutes; 100min.

[0056] The DE value and sugar profile distribution (DP) of the reaction product were measured, and the results are shown in Table 2.

[0057] The measured pH value is 6, the peak value after mixing the fresh cornstarch feed liquid with a concentration of 50% by weight and the compound amylase preparation of 25U / gDS (the enzyme activity ratio of S-type amylase and L-type amylase is 25:1) Viscosity and final value viscosity, the results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com