Gasoline engine

A technology of gasoline engine and scavenging channel, which is applied in the direction of mechanical equipment, combustion engine, machine/engine, etc., can solve the problem of large fuel loss, etc., and achieve the effect of reducing fuel loss, reducing fuel consumption and reducing escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

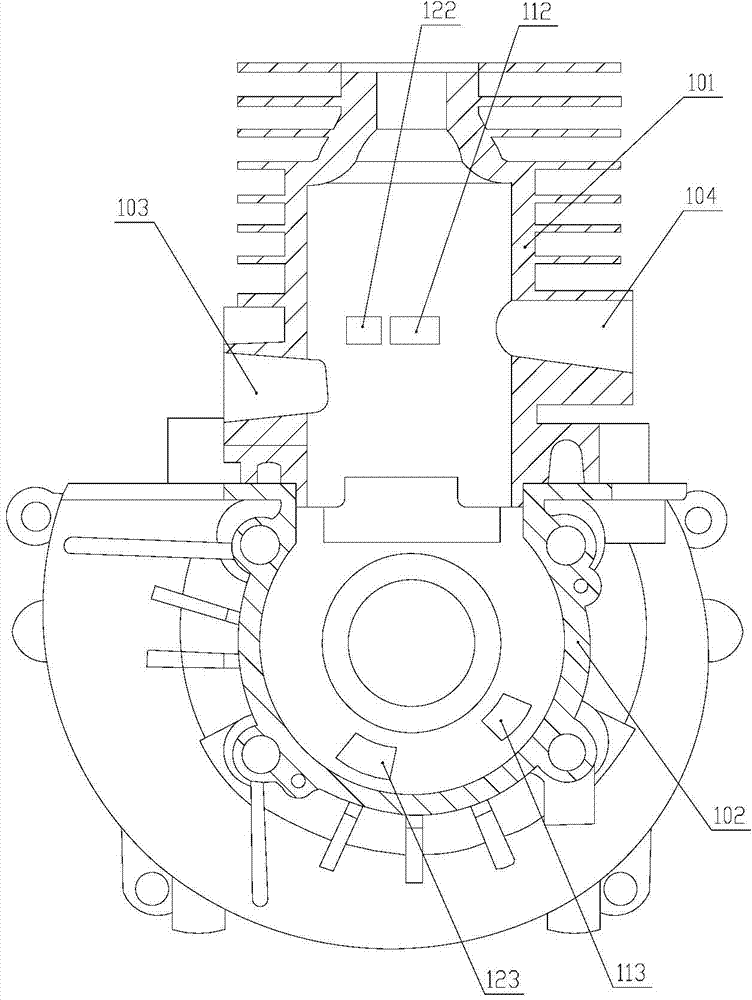

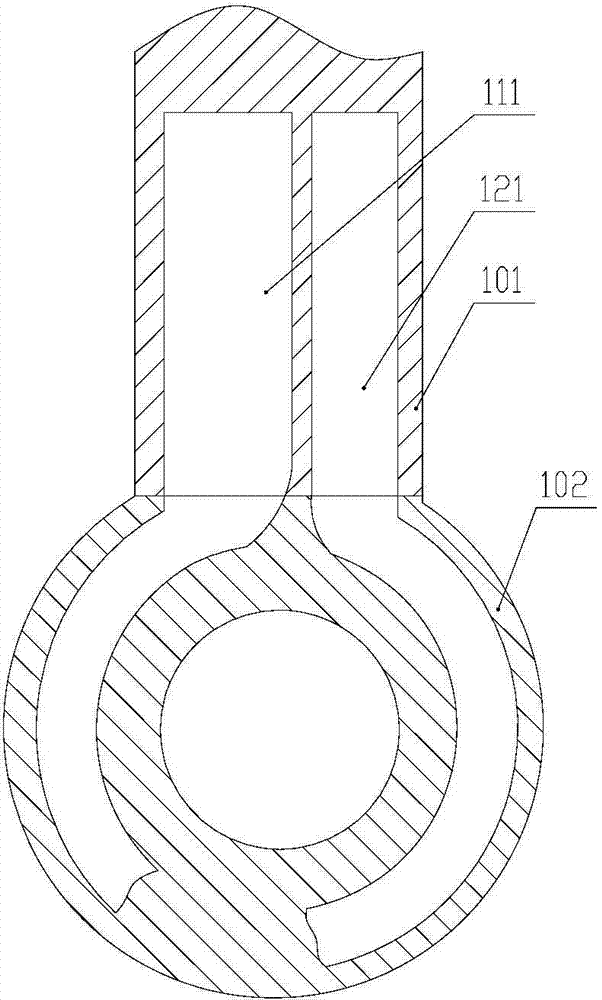

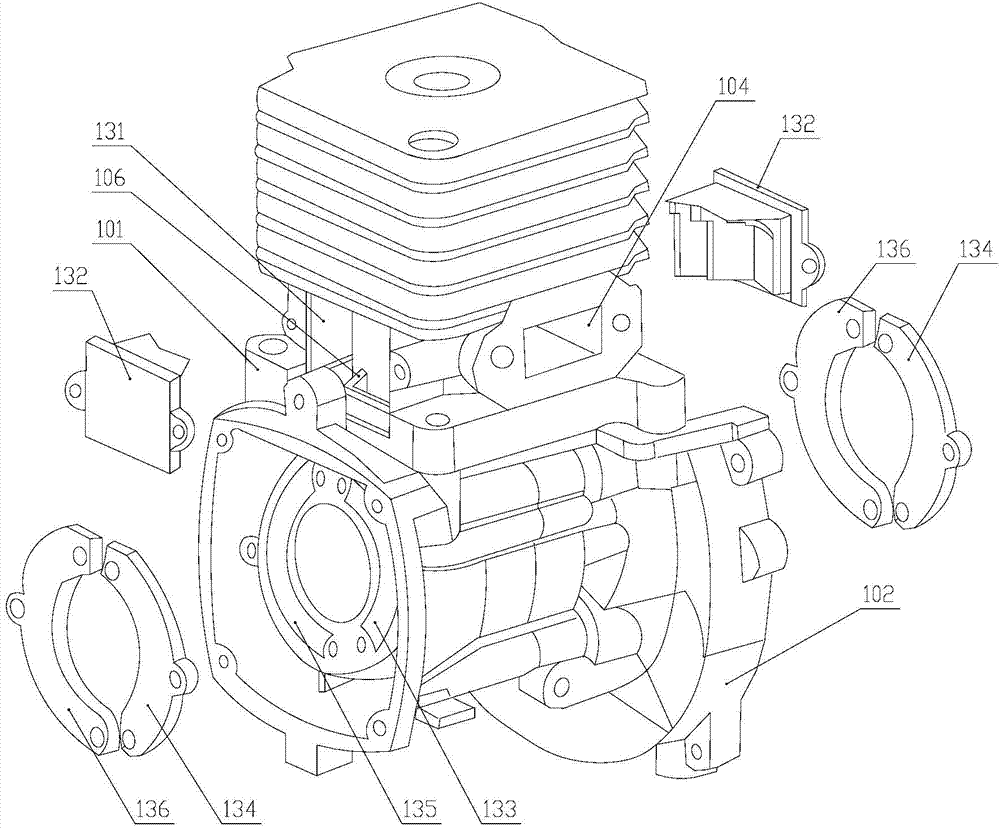

[0018] figure 1 , figure 2 It shows the gasoline engine provided by the first embodiment of the present invention, including a cylinder block 101 with a cylinder cavity and a crankcase 102 with a crank chamber, the cylinder block 101 is located above the crankcase 102, and the inner wall of the cylinder block 101 is provided with air intake holes 103. The exhaust hole 104 is also provided with a closed scavenging passage group. The scavenging passage group connects the cylinder cavity with the crank chamber. The scavenging passage group includes a first scavenging passage 111 and a second scavenging passage 121. A scavenging air passage 111 and a second scavenging air passage 121 respectively form a first scavenging air port 112 and a second scavenging air port 122 on the inner wall of the cylinder block 101. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com