Internal combustion engine economizer

A technology of fuel economizer and internal combustion engine, which is applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc. It can solve the problems of energy saving and emission reduction of internal combustion engine, complex and uncompact structure, low ozone production rate, etc., and achieve high efficiency Superior, simplified device complexity, large ozone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

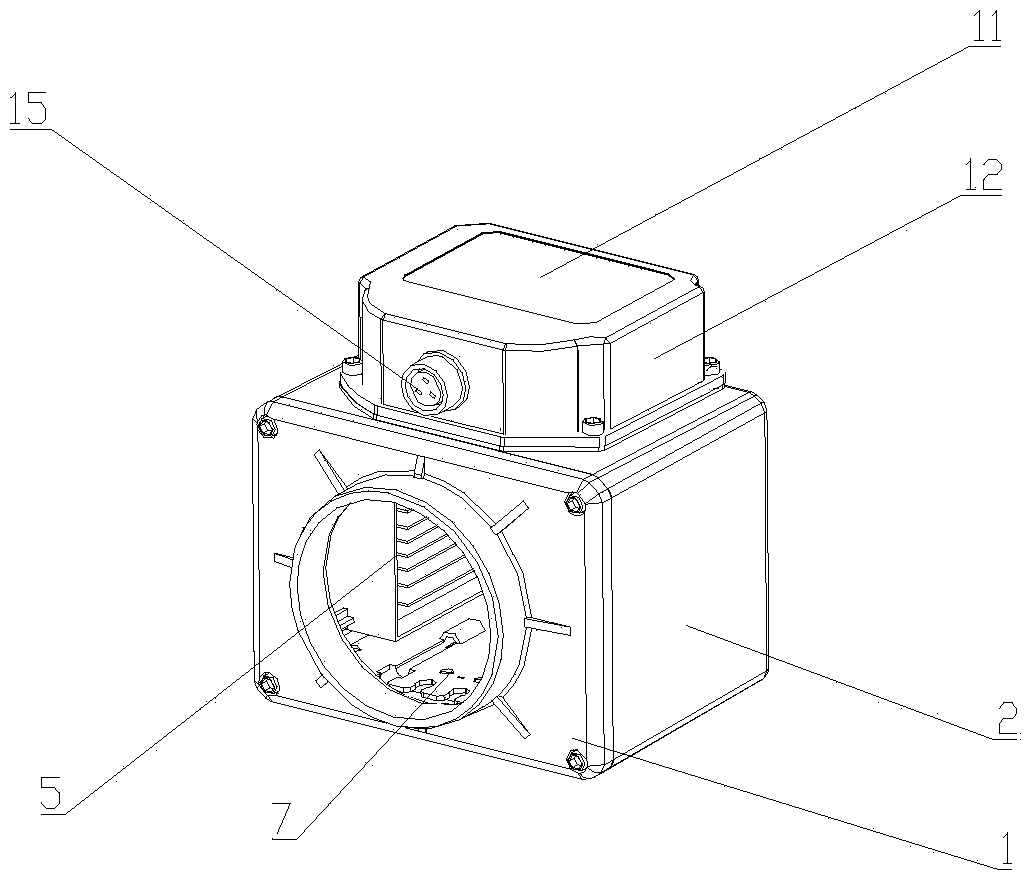

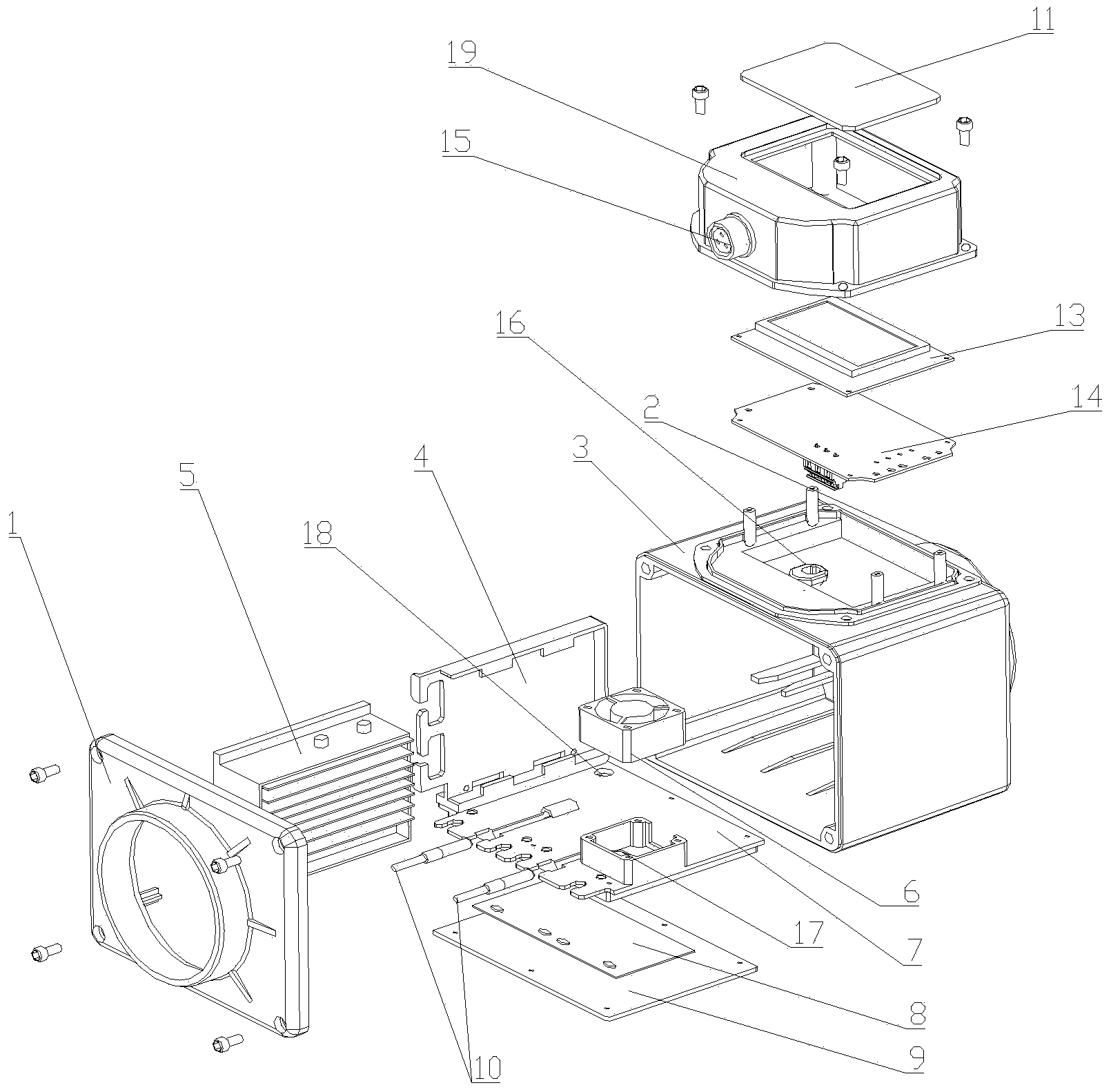

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] The internal combustion engine fuel economizer of the present invention comprises a casing 3, an ozone generating device, a power supply 5 and a control device 12, and the two ends of the casing 3 are provided with an air inlet casing cover 1 and an air outlet casing cover 2; Device 12 is arranged on the outer surface of casing 3, and it is electrically connected with ozone generator, power supply 5 respectively and controls ozone generator, power supply 4 work; The inside of casing 3 is provided with ozone generator, and described ozone generator includes Radiating fin 10, anion generating sheet 9 and wind-encapsulating cover 7 are provided with cooling fin 10 at a position close to casing 3, and described air-enclosing cover 7 is fixedly connected with cooling fin 10 to form a sealed space, and anion generating sheet 9 is arranged on Inside the sealed space, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com