An integrated device and method for gasification and incineration of organic solid waste

An organic solid, incineration device technology, applied in combustion methods, steam generators, incinerators, etc., can solve the problems of difficult to control secondary pollution, poor gasification gas quality, etc., to inhibit the resynthesis reaction and increase the flue gas temperature. , the effect of reducing the excess air coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further

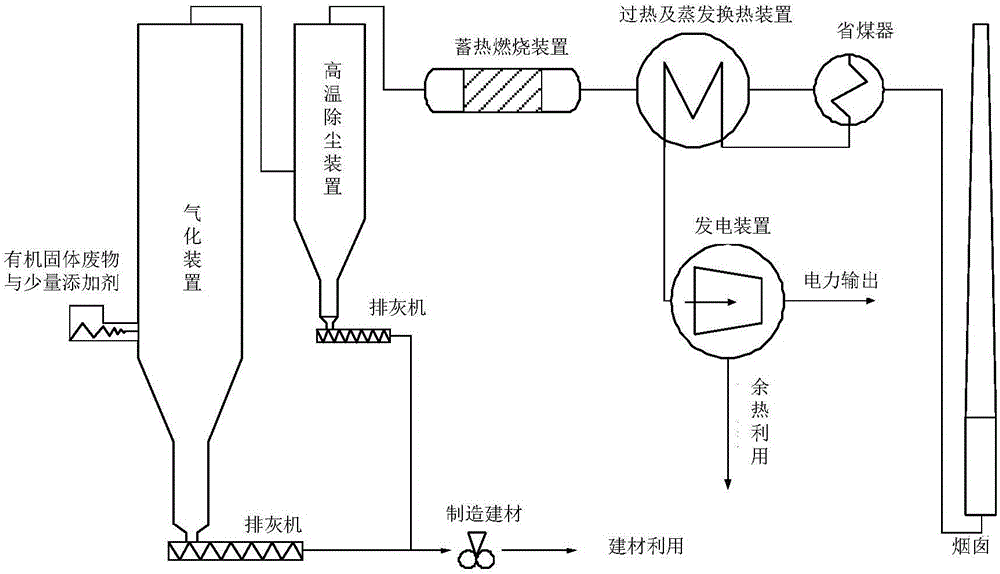

[0032]The accompanying drawing is a system diagram of a treatment device for implementing an integrated method of gasification and incineration of organic solid waste according to the present invention. As shown in the figure, organic solid waste such as household garbage and a small amount of additives are sent to the gasification device for gasification treatment at a temperature of 500-900°C; gasification gas and ash are produced during the gasification process. The generated gasification gas enters the high-temperature dust removal device for purification treatment, and the ash contained in the gasification gas is removed and separated. The temperature of the high temperature dust removal device is kept at 400-700°C. The gasification gas purified by the high-temperature dedusting device enters the regenerative incineration device for incineration, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com