Device and method for clean production of hot air by organic matters

A technology for clean production and organic matter, applied in combustion methods, lighting and heating equipment, gasification processes, etc., can solve the problems of large amount of flue gas, large heat loss of exhaust gas, loss of incomplete combustion of solids, etc., and achieve low production volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

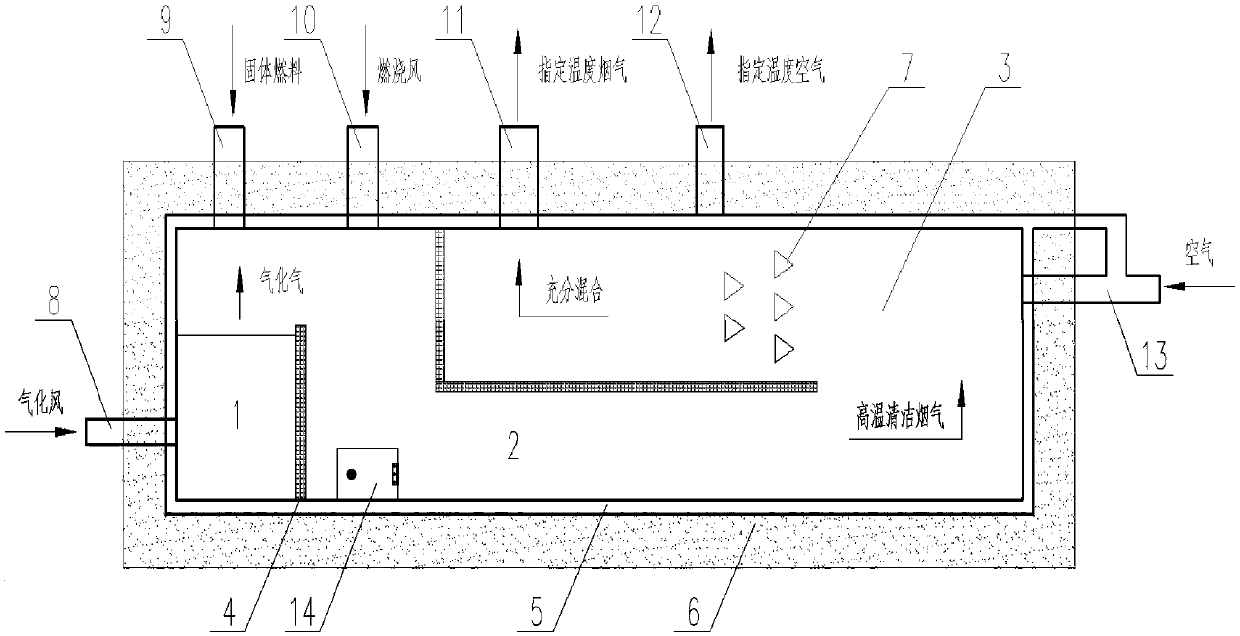

[0028] Such as figure 1 As shown, the organic matter is sent into the low-temperature vaporization chamber 1 through the closed feed inlet 9, and the gasification reaction occurs after contacting the gasification air from the gasification air inlet 8, and the gasification reaction maintains the reaction temperature between 400-900°C. The gasification reaction produces gasification gas and ash, and the gasification gas is sent to the superadiabatic combustion dust removal chamber 2, and is fully mixed with the combustion air from the combustion air inlet 10 in the superadiabatic combustion dust removal chamber 2, and a low-oxygen superadiabatic combustion reaction occurs , the reaction temperature is maintained between 1000-1500°C, the dust and tar contained in the gasification gas are removed during this process, and the generated high-temperature clean flue gas is sent to the mixing reforming chamber 3, and the high-temperature clean flue gas is mixed with the air inlet The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com