Two-stage drying and gasification integrated device and method of organic matter

A technology of a gasification device and a drying device, which is applied in the direction of drying gas arrangement, selection of absorbent solid gas purification, gas dust removal, etc., can solve problems such as large energy consumption, save energy, reduce tar composition, and tar removal rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

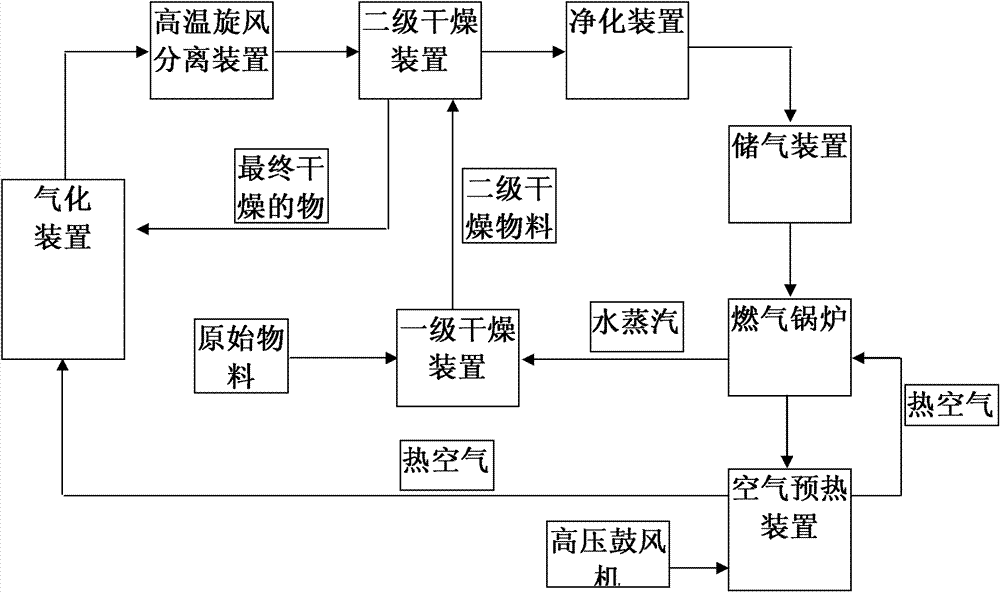

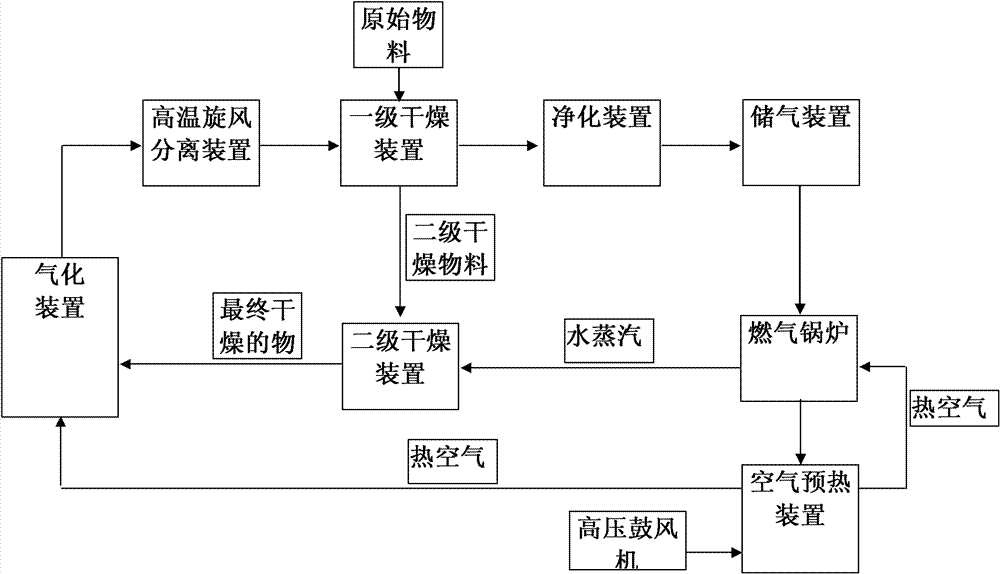

[0017] figure 1 Shown is the basic system arrangement of a treatment device for implementing an integrated method of two-stage drying and gasification of organic matter according to the present invention. Such as figure 1 As shown, high-humidity organic matter with a moisture content of 80% or higher, such as sludge produced by a sewage treatment plant, is sent to a primary drying device for drying. The drying medium is saturated water vapor. After drying, the moisture content of the organic matter decreases. 60-65%, and then these organic matter are sent to the secondary drying device for drying, the drying medium is the high-temperature combustible gas produced by the gasification device, and after drying, the final dry organic matter is formed, and its moisture content is 20-25%; The final treated organic matter is solid fuel, which undergoes gasificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com