Control method for oil purifier integrated with automatic detection and purification, and intelligent controller thereof

An intelligent controller and automatic detection technology, applied in computer control, program control, general control system, etc., can solve the problems of untimely purification, oil deterioration, and failure to achieve intelligent operation, so as to reduce the failure of oil-using equipment, The effect of prolonging the service life of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

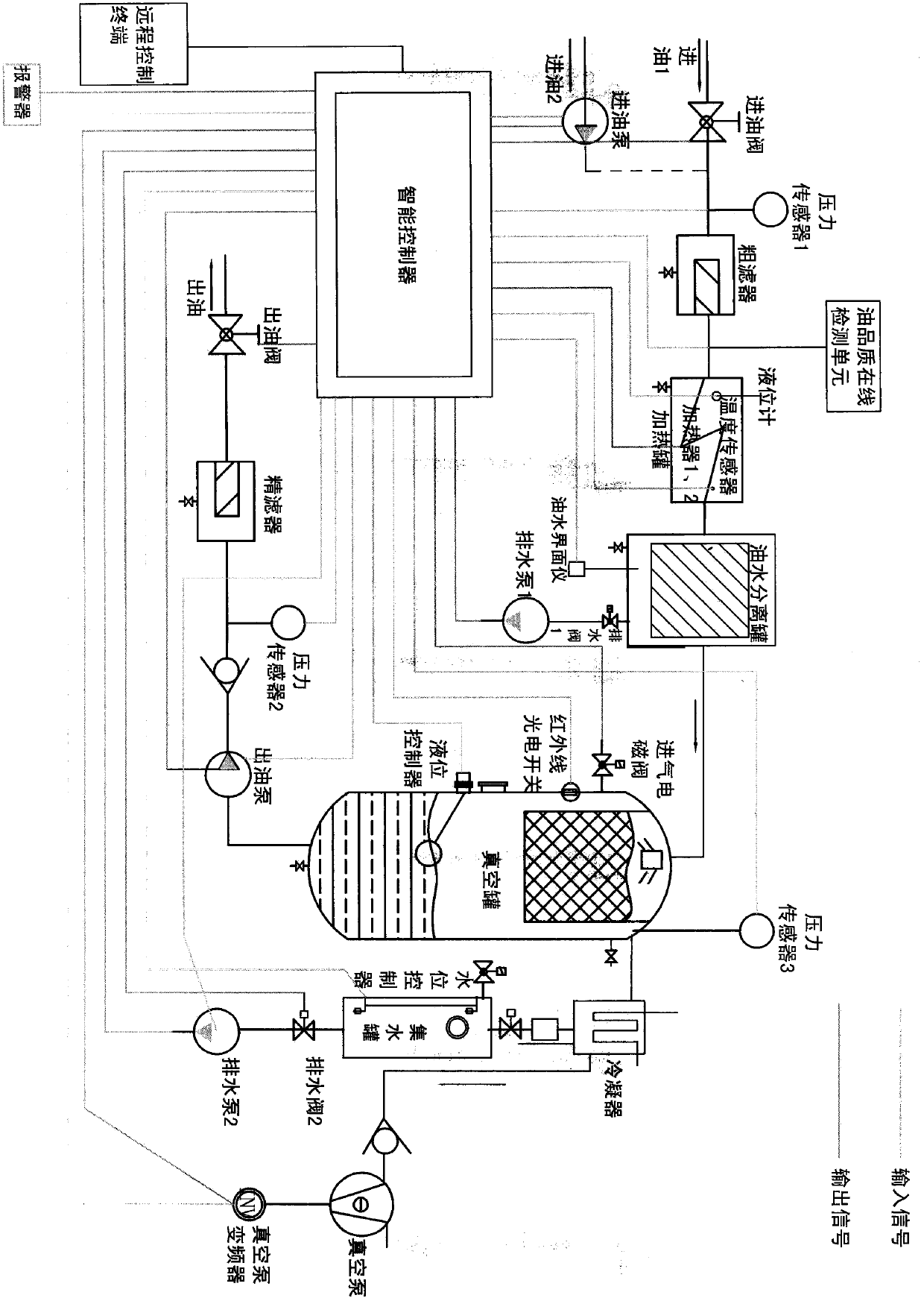

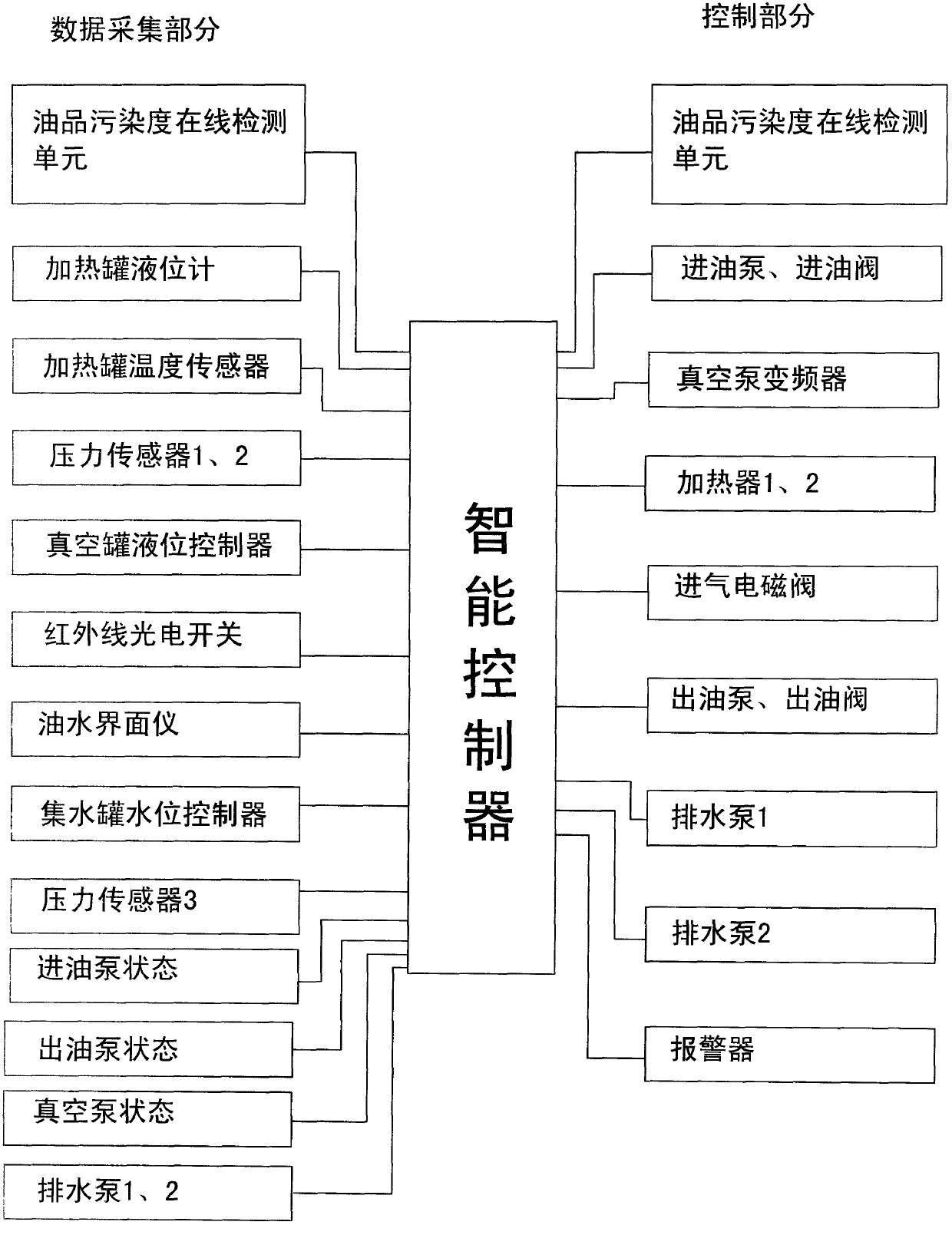

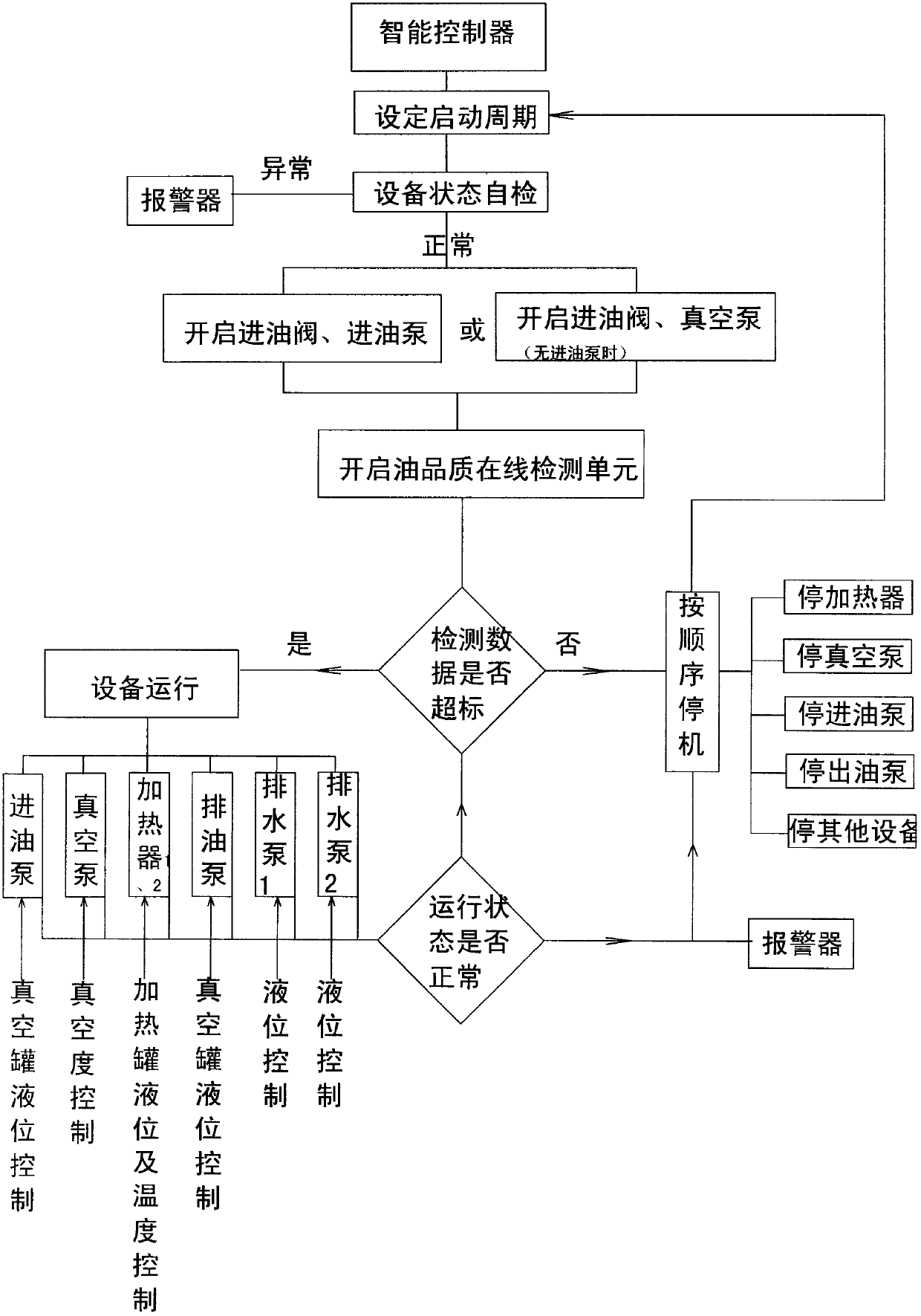

[0017] like figure 1 , figure 2 As shown, this embodiment is aimed at realizing intelligent control of an automatic detection and purification integrated oil purifier. The composition of the equipment mainly includes: oil inlet valve, oil inlet pump (when used for low-viscosity oil purification, no oil inlet pump is provided, and the oil is sucked by a vacuum pump), pressure sensor 1 on the oil inlet pipeline, coarse filter, oil quality online detection unit (mainly detects Moisture in oil and particle pollution, but not limited to these two parameters), heating tank (with two-stage heaters 1 and 2, liquid level gauge, temperature sensor), oil-water separation tank (with oil-water interface instrument, drain valve 1 and drain pump 1), vacuum tank (with pressure sensor 3, infrared photoelectric switch, intake solenoid valve, liquid level con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com