A cleaning method related to mechanical equipment oil circuit without disassembly and high-voltage static electricity

A high-voltage electrostatic and mechanical equipment technology, which is applied in the field of high-voltage electrostatic cleaning of the oil circuit of mechanical equipment without disassembly, can solve the problems of incomplete cleaning and complicated operation, and achieve the effects of avoiding equipment damage, simple operation, and light equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

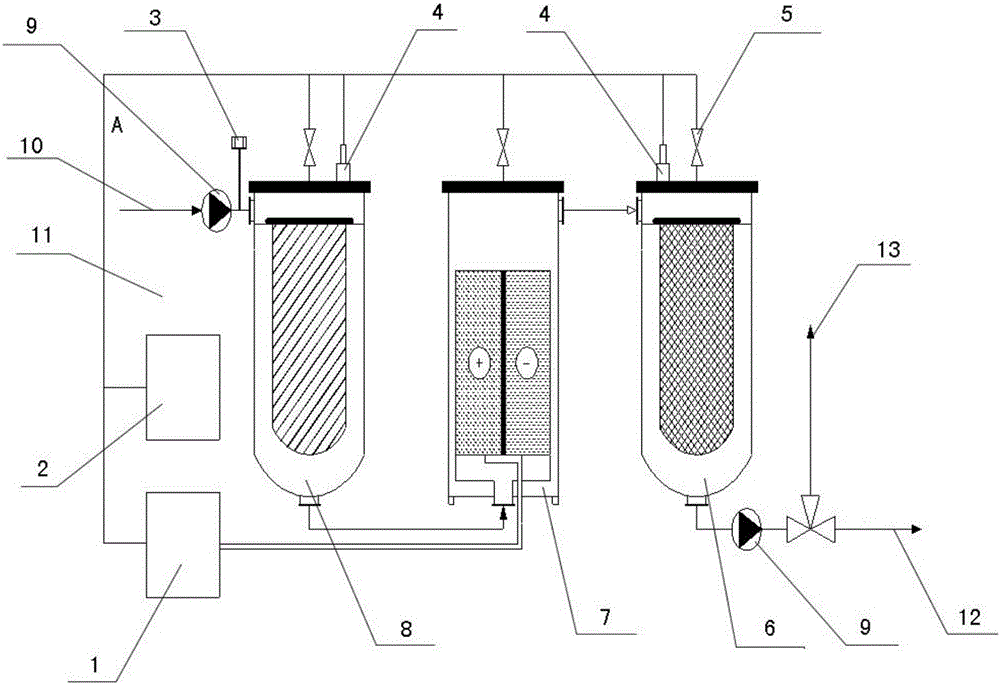

[0019] The invention relates to a disassembly-free high-voltage electrostatic cleaning device for the oil circuit of mechanical equipment, including a pressure sensor, a stop valve, a pollution degree detector, a control system, a high-voltage electrostatic generator, a coarse filter tank, a balanced electronic filter tank, a pump, a high-voltage The nozzle and the filter device are composed of a coarse filter tank and a balanced electronic filter tank. A pressure sensor is respectively installed on the upper part of the coarse filter tank and the balanced electronic filter tank. The signal line A is connected to the input signal line of the control system, and the output signal line of the control system is connected to the high-voltage electrostatic generator. The signal input terminal of the high-voltage electrostatic generator is connected to the signal input terminal of the balanced charge reverberation device. The inlet of the coarse filter tank is connected to the outlet ...

Embodiment 2

[0026] Shanghai Tunnel Company’s Jinmen shield machine needed oil change during the construction of the Nanjing River Crossing Tunnel in July 2013. After discarding the old oil, the device of the present invention was used to clean the oil circuit. After cleaning, new oil was added. The added oil was tested The pollution level of the new oil is NAS7. After one hour of operation, it is still NAS7. After one month of use, it is still NAS7. After five months of use, it is NAS8, which is still within the normal range. Others have not been oiled. After adding new oil to the cleaned equipment, it will be NAS8 after one hour of operation. After one month of use, it will be detected as NAS9. After three months of use, it will be detected as NAS10 or above. The oil needs to be changed again. Substantial improvement, maintenance rate is greatly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com