Machine tool for the production of profiles

一种机床、轮廓的技术,应用在机床领域,能够解决昂贵等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

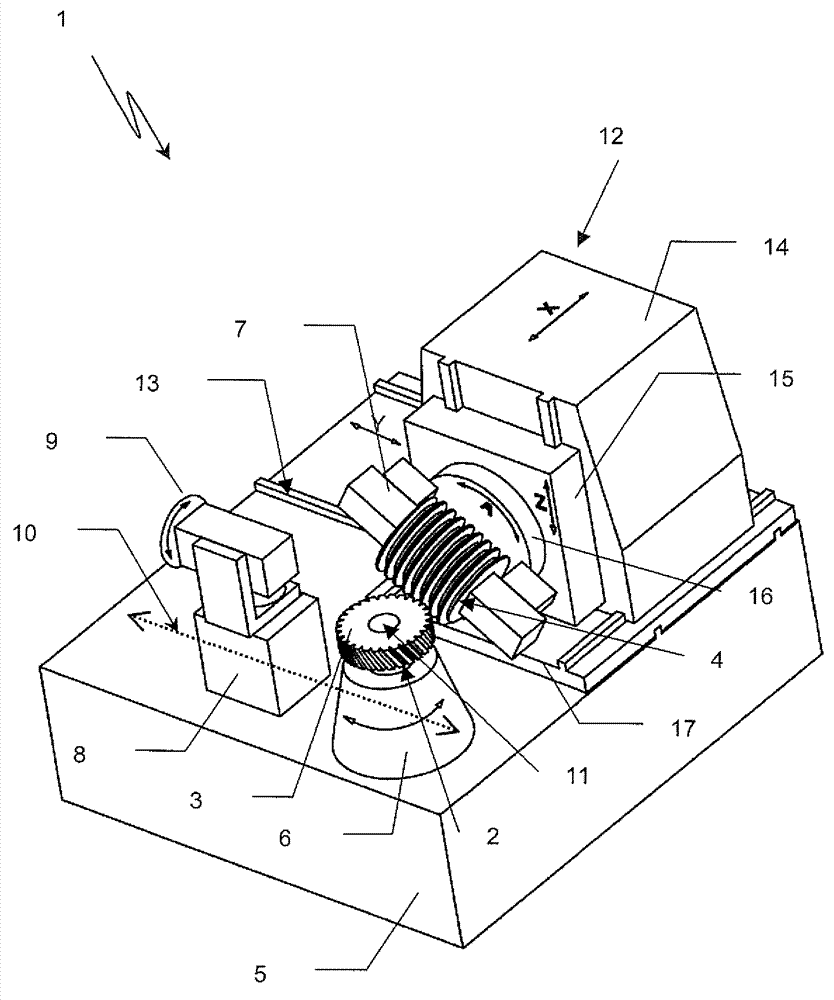

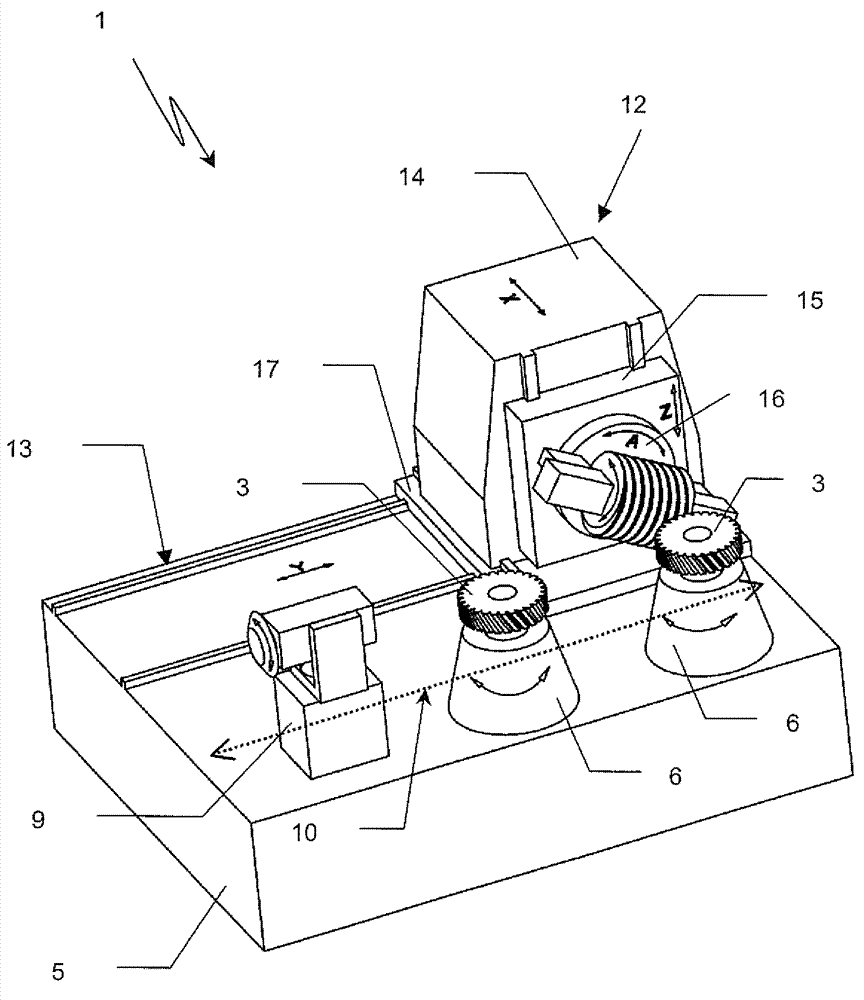

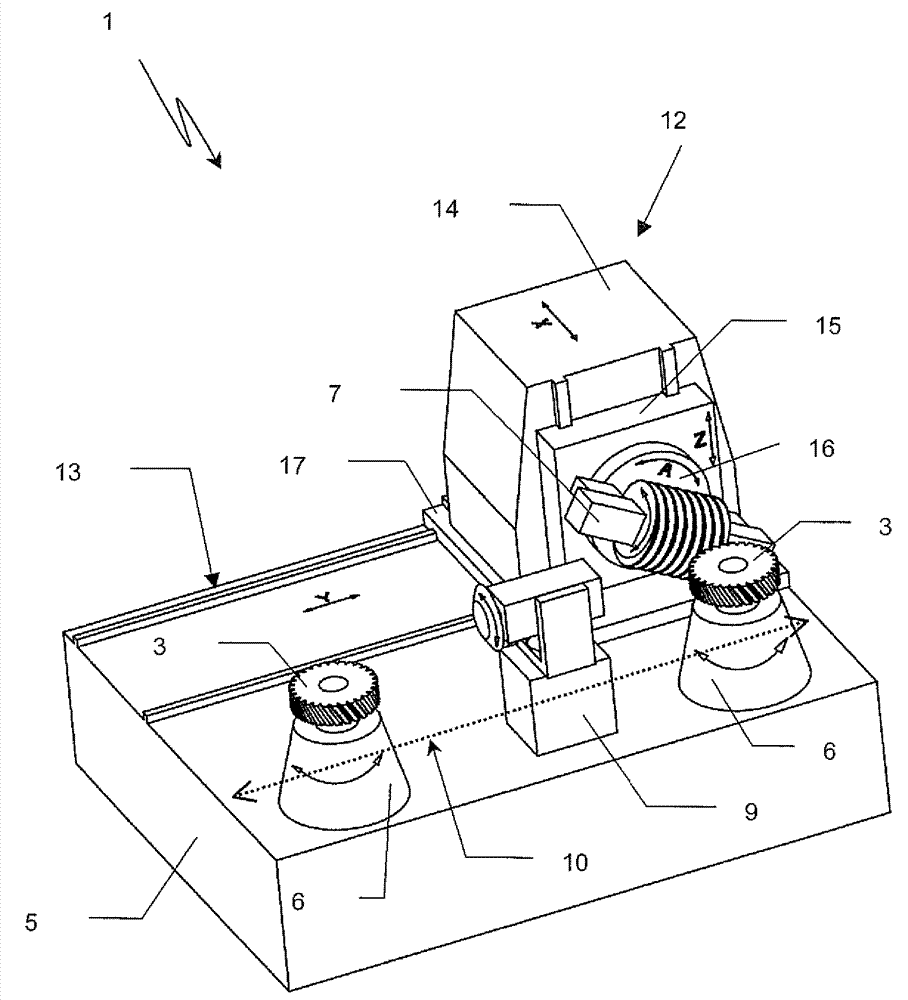

[0026] figure 1 In a perspective view is shown a first machine tool 1 according to the invention for producing a gear shaping system 2 on a workpiece 3 by means of a rotor-driven machining tool 4 by roll grinding, profile grinding or roll milling. Exemplary embodiment. The machine tool 1 has a machine bed 5 on which a workpiece receiving device 6 is arranged for tensioning and rotating a workpiece 3 , and a workpiece processing device 7 for processing the workpiece 3 received by the workpiece receiving device 6 . The workpiece processing device 7 carries and drives the processing tool 4 for the workpiece 3 . A machining tool profiling device 8 is arranged on the left next to the workpiece receiving device 6 with the workpiece 3 , said profiling device having a dressing tool 9 for regular dressing and profiling of the machining tool 4 . The workpiece receiving devices 6 and the machining tool shaping devices 8 form a row 10 .

[0027] The workpiece receiving device 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com