Low-molecular-weight pectin composite flocculant and online extraction process thereof

A low-molecular-weight pectin and composite coagulation technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, can solve the problems of unfavorable solid-liquid separation, affecting the quality of pectin, and wasting energy, so as to reduce equipment investment and site occupancy, Reduce the cost of sewage treatment, good coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

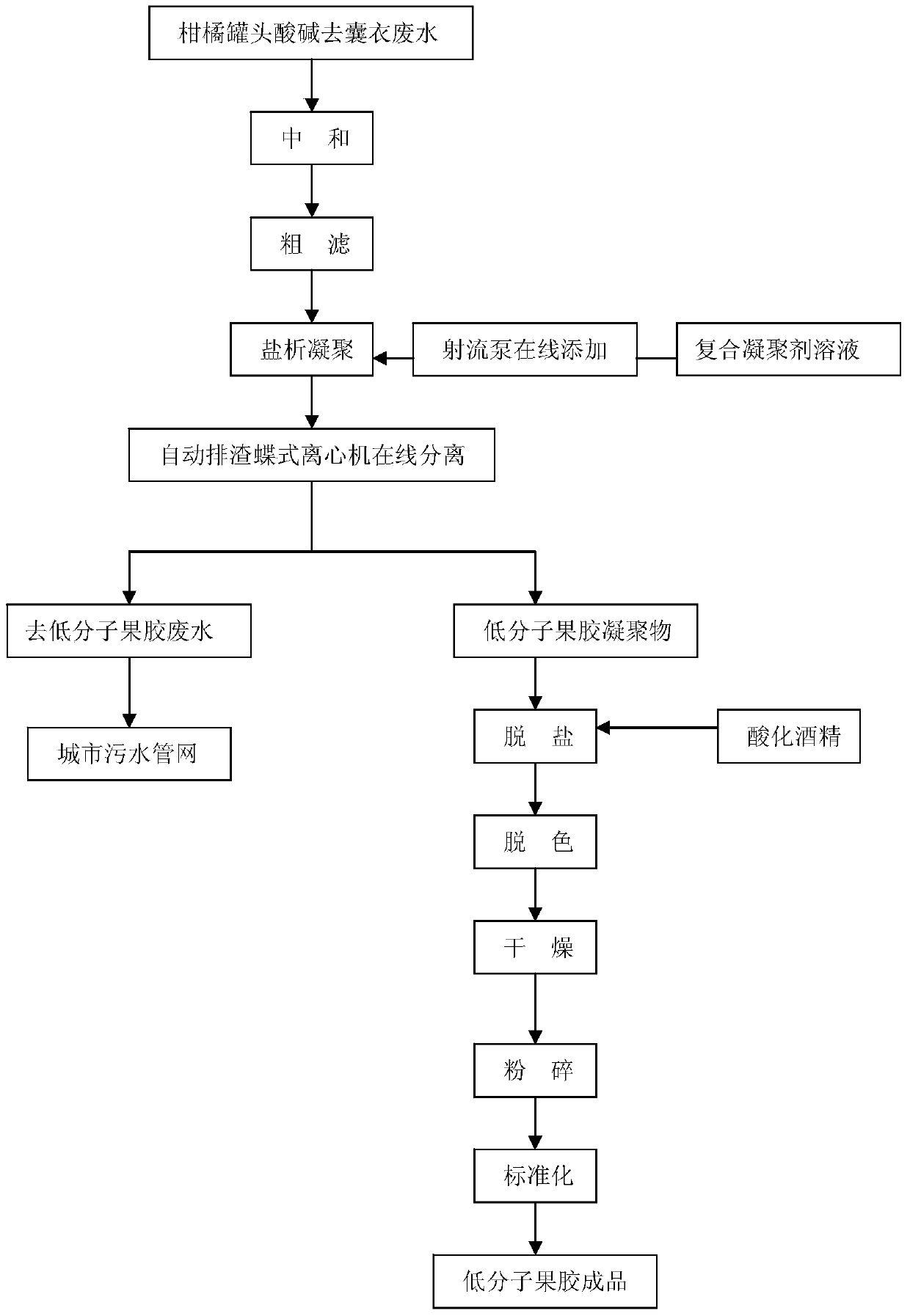

[0039] The online extraction process 1 of low-molecular-weight pectin in citrus canned processing waste liquid comprises the following steps in sequence:

[0040] a) Neutralization: mix the acid solution and lye solution of the citrus peeled coat in the neutralization tank, and adjust the pH value of the mixed solution to neutral;

[0041] b) Coarse filtration: filter the mixed solution with an 80-mesh filter to remove coarse impurities such as tangerine and capsule fragments;

[0042] c) Preparation of composite coagulant solution: by mass parts, 95 parts of calcium chloride and 5 parts of magnesium chloride are mixed to make composite coagulant; then by mass parts, 70 parts of water and 30 parts of composite coagulant are mixed with Made into an aqueous solution for use;

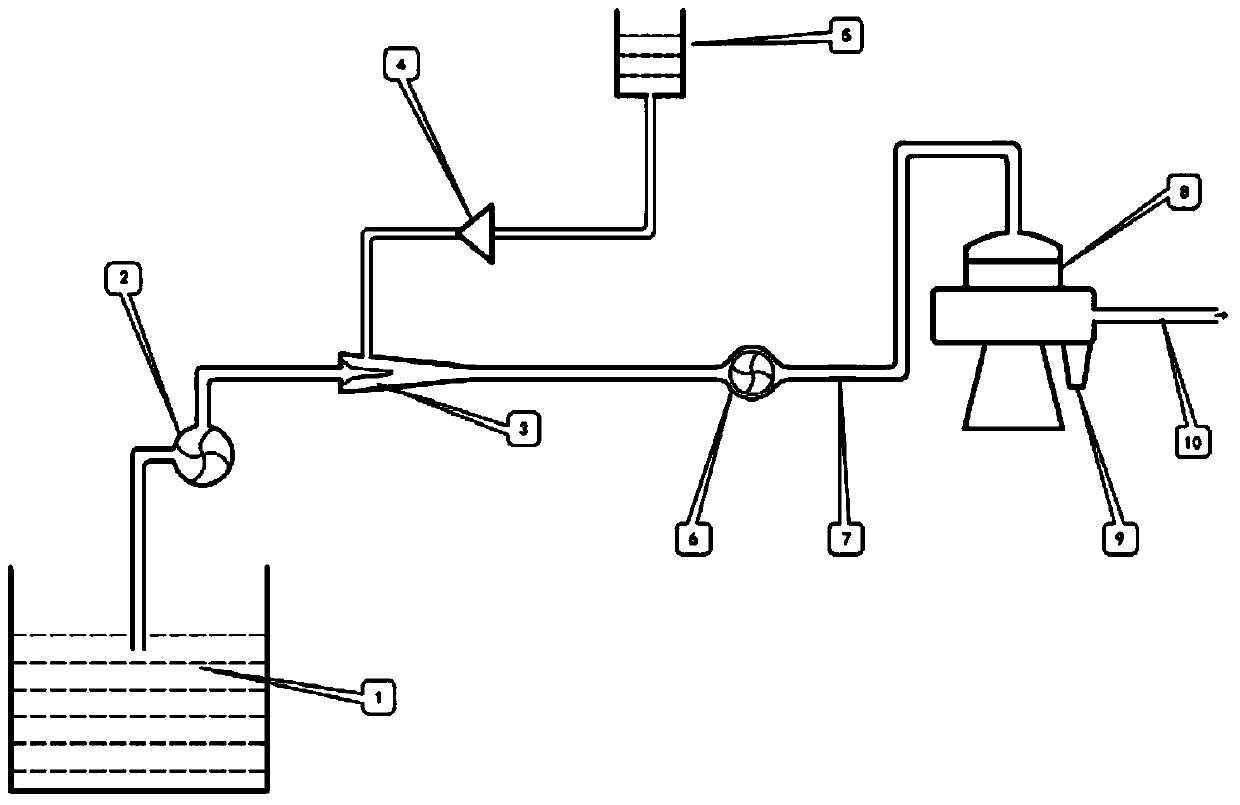

[0043] d) Online addition of composite coagulant solution: use a jet pump to add online according to the ratio of the solid mass of composite coagulant to 0.05% of the total mass of canned citrus waste li...

Embodiment 2

[0049] The online extraction process 2 of low-molecular-weight pectin in canned citrus processing waste liquid includes the following steps in sequence:

[0050] a) Neutralization: mix the acid solution and lye solution of the citrus peeled coat in the neutralization tank, and adjust the pH value of the mixed solution to neutral;

[0051] b) Coarse filtration: filter the mixed solution with a 100-mesh filter to remove coarse impurities such as tangerine and capsule fragments;

[0052]c) Preparation of composite coagulant solution: by mass parts, 80 parts of calcium chloride and 20 parts of magnesium chloride are mixed to make composite coagulant; then by mass parts, 70 parts of water and 30 parts of composite coagulant are mixed with Made into an aqueous solution for use;

[0053] d) Online addition of composite coagulant solution: use a jet pump to add online according to the ratio of the solid mass of composite coagulant to 0.03% of the total mass of canned citrus waste liq...

Embodiment 3

[0059] The online extraction process 3 of low-molecular-weight pectin in canned citrus processing waste liquid includes the following steps in sequence:

[0060] a) Neutralization: mix the acid solution and lye solution of the citrus peeled coat in the neutralization tank, and adjust the pH value of the mixed solution to neutral;

[0061] b) Coarse filtration: filter the mixed solution with a 120-mesh filter to remove coarse impurities such as tangerine and capsule fragments;

[0062] c) Preparation of composite coagulant solution: by mass parts, 90 parts of calcium chloride and 10 parts of magnesium chloride are mixed to make composite coagulant; then by mass parts, 80 parts of water and 20 parts of composite coagulant are mixed with Made into an aqueous solution for use;

[0063] d) Online addition of composite coagulant solution: use a jet pump to add online according to the ratio of the solid mass of composite coagulant to 0.08% of the total mass of canned citrus waste li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com