A heating system for centralized lubrication pipeline and its application method

A heating system and centralized lubrication technology, applied in the direction of lubricating parts, engine lubrication, engine components, etc., can solve the problems of many branch pipelines, parts cannot be lubricated, blocked, etc., to achieve uniform heat distribution and uniform heating effect. , the effect of high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following description is only for explaining the present invention and not limiting its content.

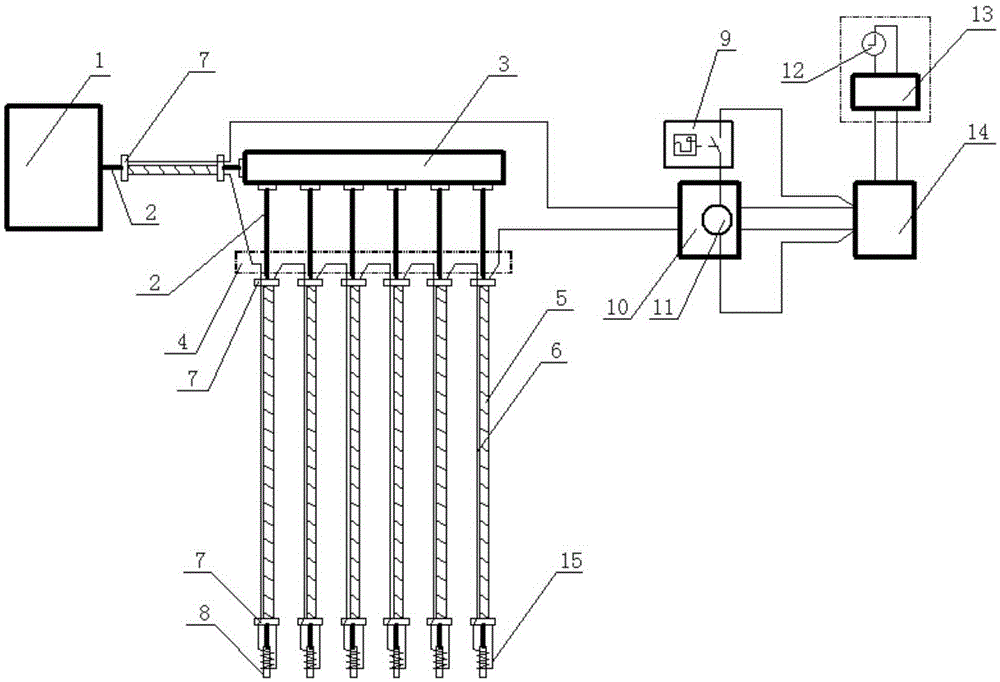

[0040] Such as figure 1 As shown, the present invention is a heating system for lubricating pipelines, which includes: electric heating oil pipe, return line 6, summary terminal block, connecting ring 7, power supply 13, temperature control switch 9, timer 12 , Contactor 10, circuit breaker 14, external resistance wire 15.

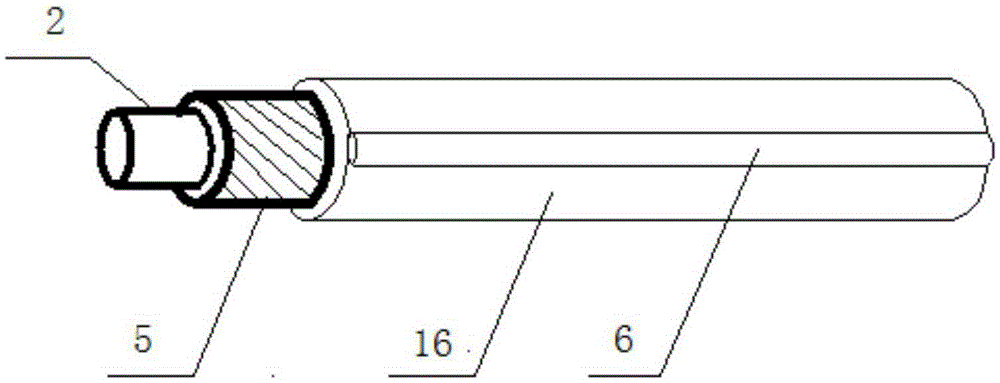

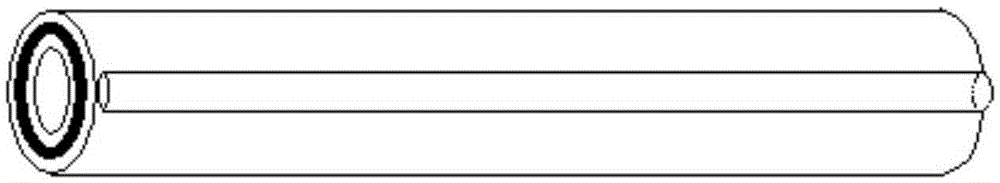

[0041] The structure of the electric heating oil pipe is similar to the shielded cable style, and the inner heating net is tightly wrapped on the outer wall of the inner oil pipe 2, and the internal lubricating pipeline is electrically heated by an external power supply, and the electric heating net 5 is wrapped with an insulating insulation layer.

[0042] The power source 13 is AC or DC.

[0043] The retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com