Ion source with evaporator

An ion source and evaporator technology, applied in the field of ion sources with evaporators, can solve the problems of reduced evaporation rate, uneven distribution of materials to be evaporated, uneven material evaporation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] A detailed description of the present invention will be discussed by means of the following examples, which are not intended to limit the scope of the present invention, but may be applicable in other applications. The drawings reveal some details, it must be understood that details of the design of the disclosed elements may differ from what has been disclosed, except in the case of explicit limitations on the characteristics of the elements.

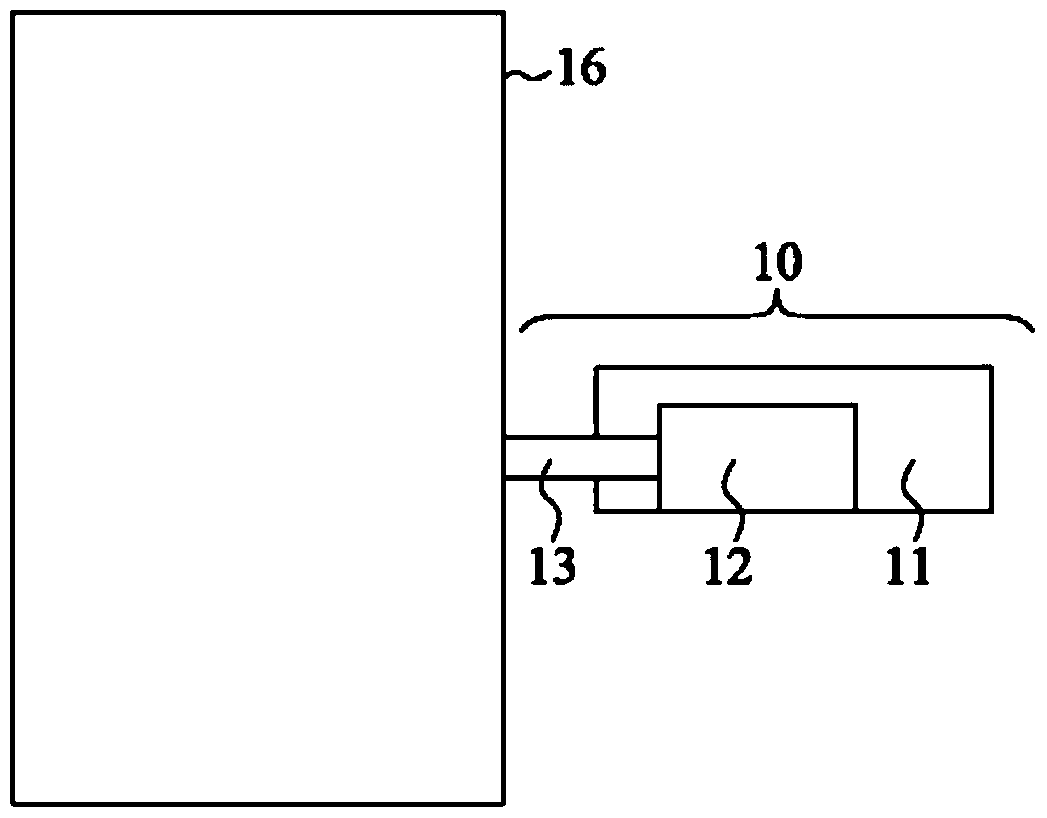

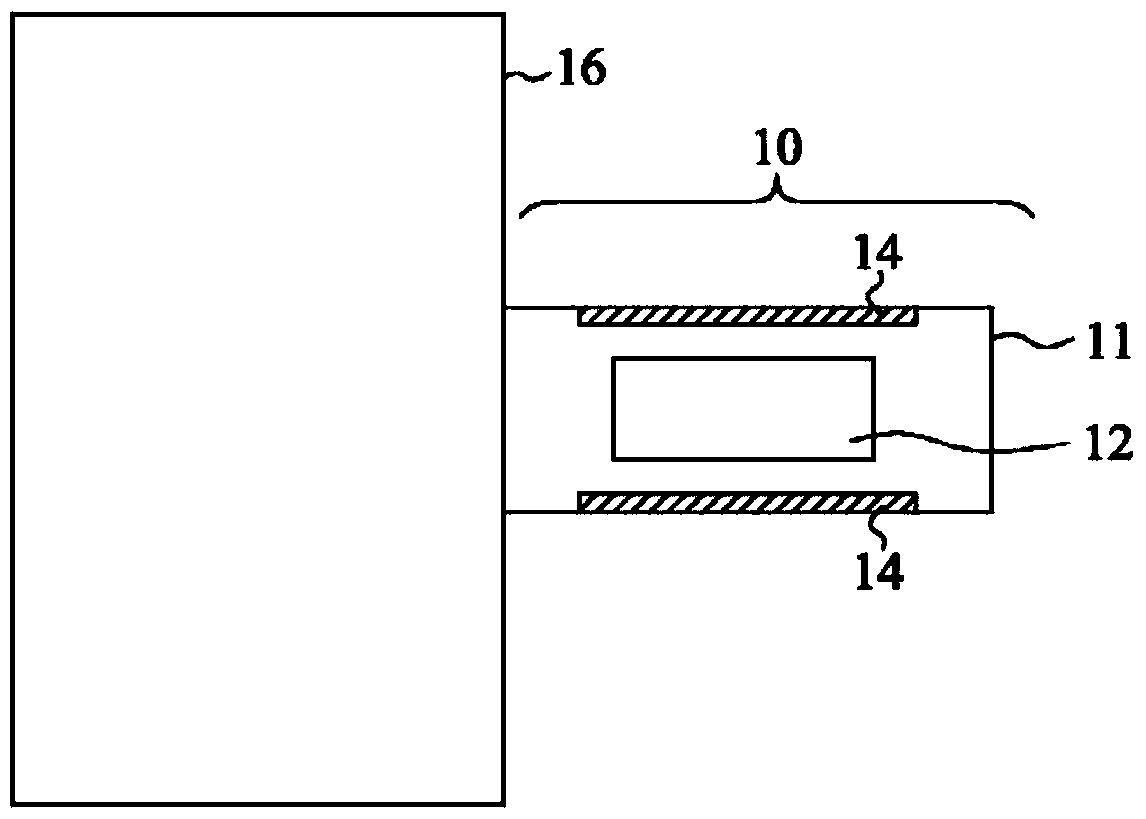

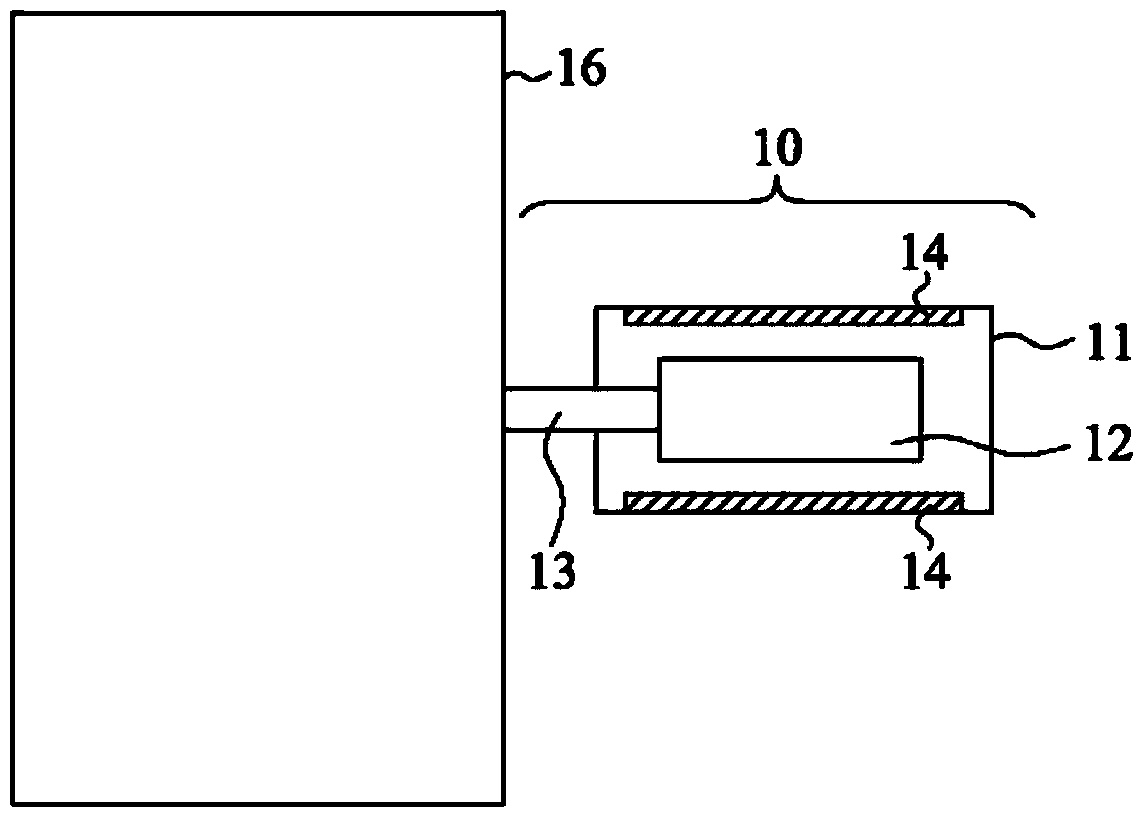

[0075] The ion source of an embodiment of the present invention is as Figure 2A and Figure 2B As shown, the evaporator 20 is disposed adjacent to the adjacent arc chamber 29 so that the material to be evaporated in the evaporator 20, whether solid or liquid, can be evaporated and then transferred into the arc chamber 29 so that the arc chamber 29 has a large amount of A plasma of ions of the desired species. In addition, the evaporator 20 has at least a housing 21 adjacent to the arc chamber 29, a container 22 arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com