Mussel soy sauce and production method thereof

A production method and technology of mussels, applied in the field of mussel soy sauce and its production, can solve the problems of low price, taste, nutritional limitations, and low economic added value, and achieve high nutritional value, rich varieties, and high-value utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

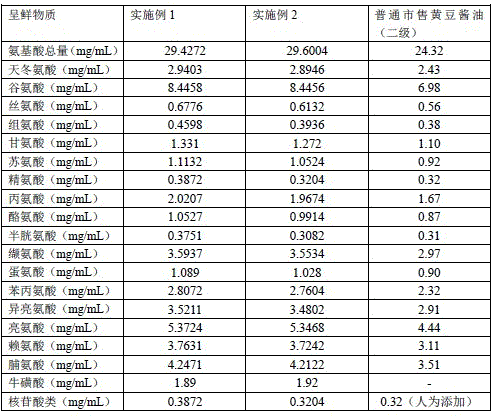

Examples

Embodiment 1

[0023] 1) Cooking mussel broth: After 1 ton of tap water is heated to boil, add 0.65 tons of mussels, keep for 0.5 minutes after boiling, then remove the mussels; then add 0.5 tons of mussels, keep for 0.5 minutes after boiling, Remove the mussels, then add 0.5 tons of mussels, keep boiling for 0.5 minutes, remove the mussels, and then go back and forth for 5 times to get the mussels boiling soup, about 0.6 tons.

[0024] 2) Soup concentration: the mussel soup is cooled, then slightly boiled or steamed under reduced pressure, concentrated to 0.4 tons, and then transferred to the fermentation tank. The fermentation tank can be a large plastic tank or a metal tank, and the metal tank is preferred.

[0025] 3) Preparation of mussel fermented liquid: mixed strains are used for the fermentation of mussel boiled broth, wherein the mixed strains are composed of Aspergillus oryzae, Aspergillus sojae, Aspergillus usami and Pediococcus sojae according to 50%, 30%, 15% and 5% % ratio com...

Embodiment 2

[0030] 1) Cooking mussel broth: After 1 ton of tap water is heated to boil, add 0.65 tons of mussels, keep for 0.5 minutes after boiling, and then remove the mussels; then add 0.5 tons of mussels, keep for 0.5 minutes after boiling, remove the mussels ; Then add 0.5 tons of mussels, keep for 0.5min after boiling, and remove. After going back and forth like this for 5 times, the broth made from mussels is about 0.7 tons.

[0031] 2) Soup concentration: the mussel soup is cooled, then slightly boiled or steamed under reduced pressure, concentrated to 0.4 tons, and then transferred to the fermentation tank. The fermentation tank can be a large plastic tank or a metal tank, and the metal tank is preferred.

[0032] 3) Preparation of mussel fermented liquid: mixed strains are used for the fermentation of mussel boiled broth, wherein the mixed strains consist of Aspergillus oryzae, Aspergillus sojae, Aspergillus usami and Pediococcus sojae according to 55%, 25%, 15% and 5% % ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com