Input type ultrasonic washer-disinfector for kitchens

A cleaning-disinfector and ultrasonic technology, applied in kitchen utensils, applications, home utensils, etc., can solve the problems of low operating frequency of ultrasonic waves, limited degradation ability, increased use cost, etc., to reduce cavitation corrosion, low installation cost, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

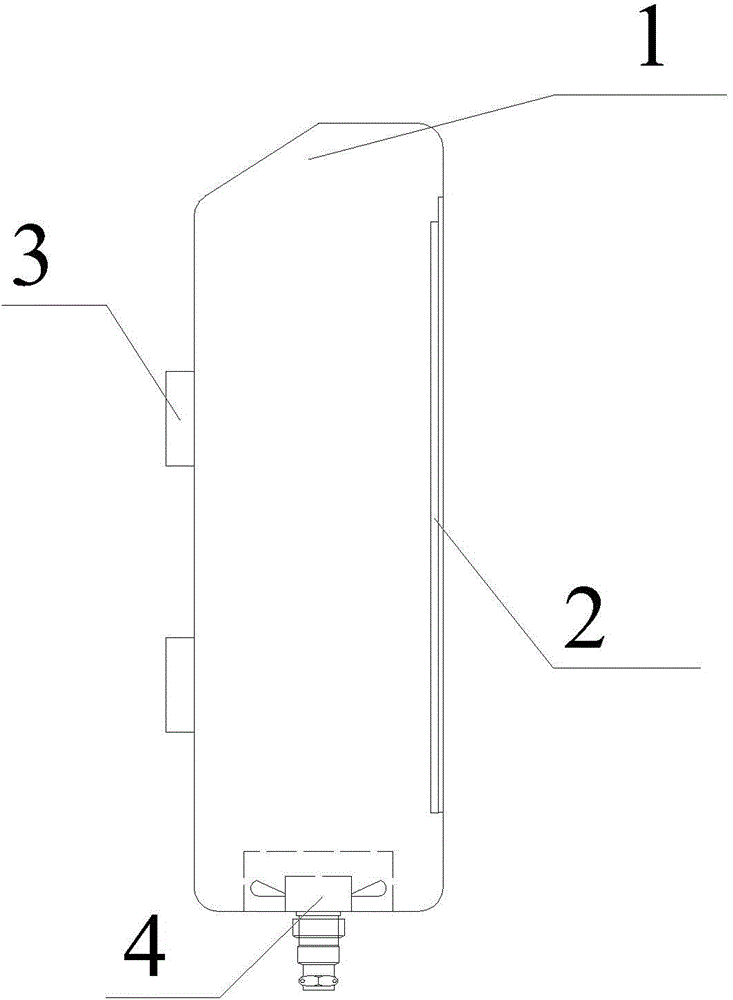

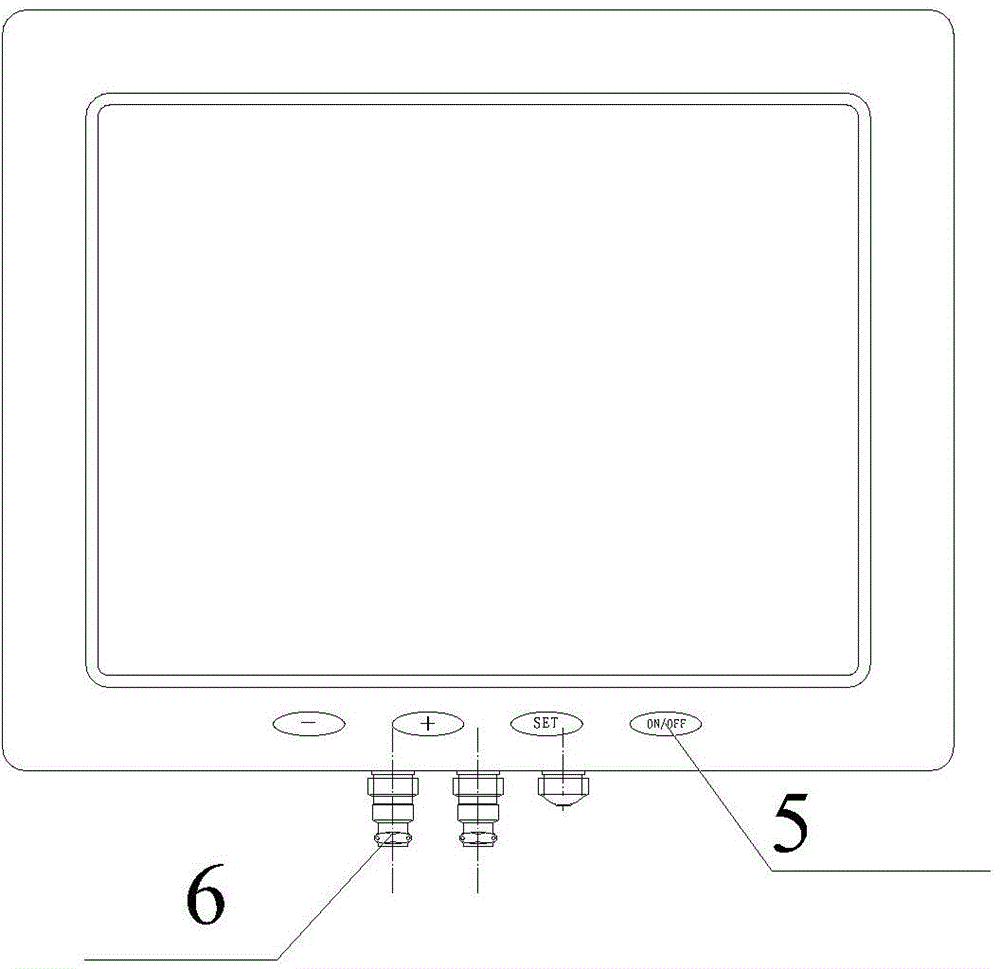

[0021] figure 1 with figure 2 Two views of the controller of the present invention are shown, wherein the front of the controller housing 1 is provided with a liquid crystal display 2, and the operation button 5 is arranged below the liquid crystal display 2; the back of the controller housing 1 is provided with a mounting part 3; the control The bottom of the controller housing 1 is provided with a cooling fan 4, an ozone / ultrasonic signal output port 6 and a power input port;

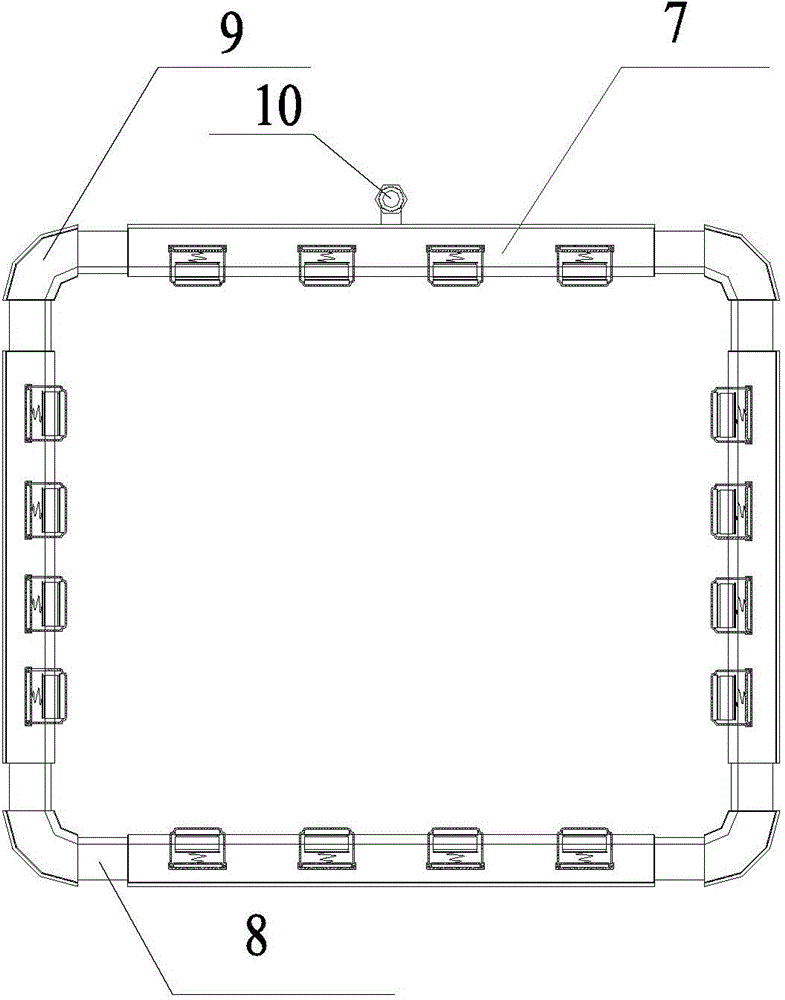

[0022] image 3 with Figure 4 Two views of the actuator of the present invention are shown, including sixteen groups of ultrasonic cleaning heads 11, a frame and a power supply. The thin extension part 8, the extension part 8 matches the elbow 9, and the size of the frame can be adjusted by adjusting the depth of the extension part 8 inserted into the elbow 9; the ultrasonic cleaning head 11 is fixed on one end of the column 14 perpendicular to the frame plane, The other end of the column 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com