A kind of preparation method of magnetically loaded tio2 composite photocatalyst material

A catalyst and composite light technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Low light source utilization rate and other problems, to achieve the effect of preventing photomelting, easy operation, and high light source utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

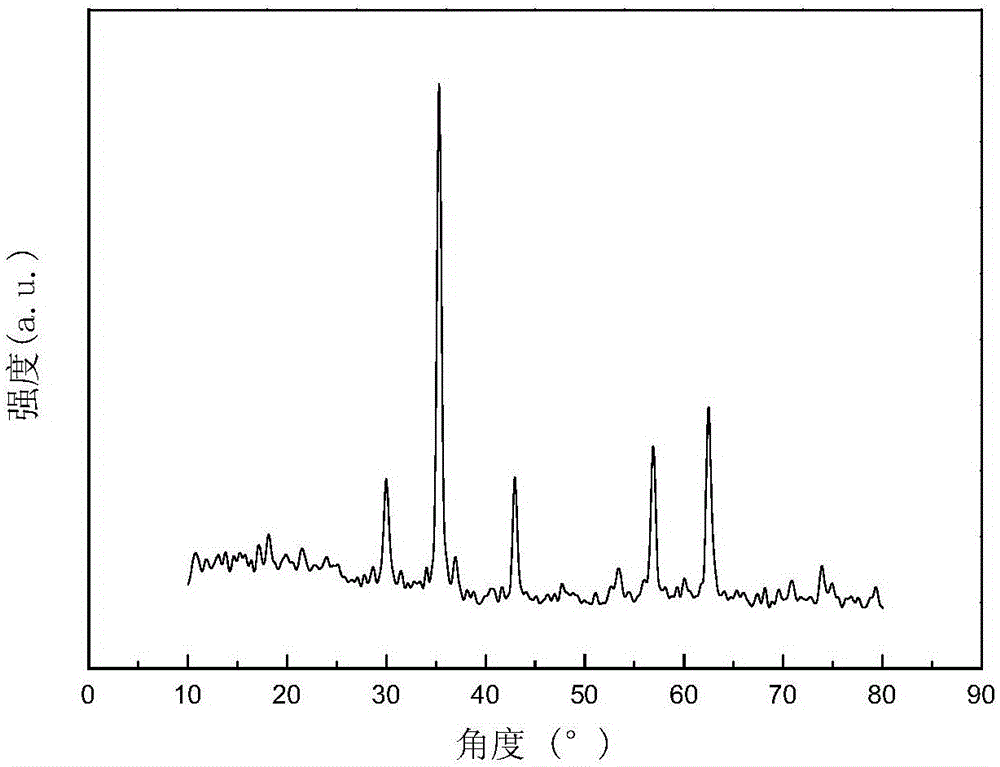

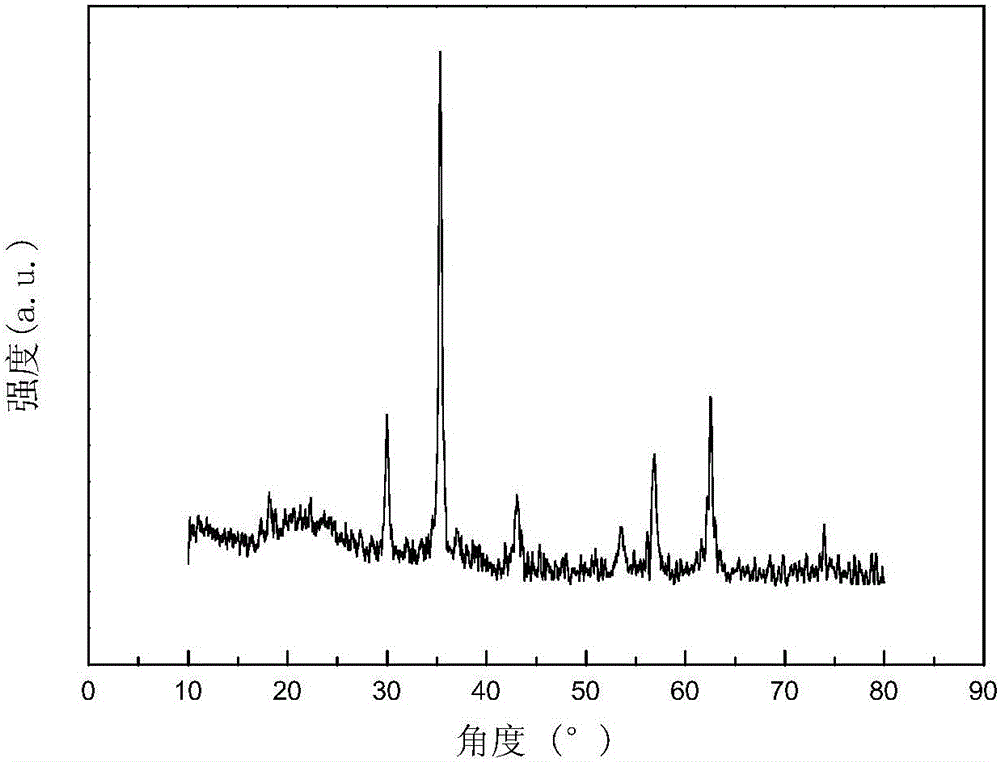

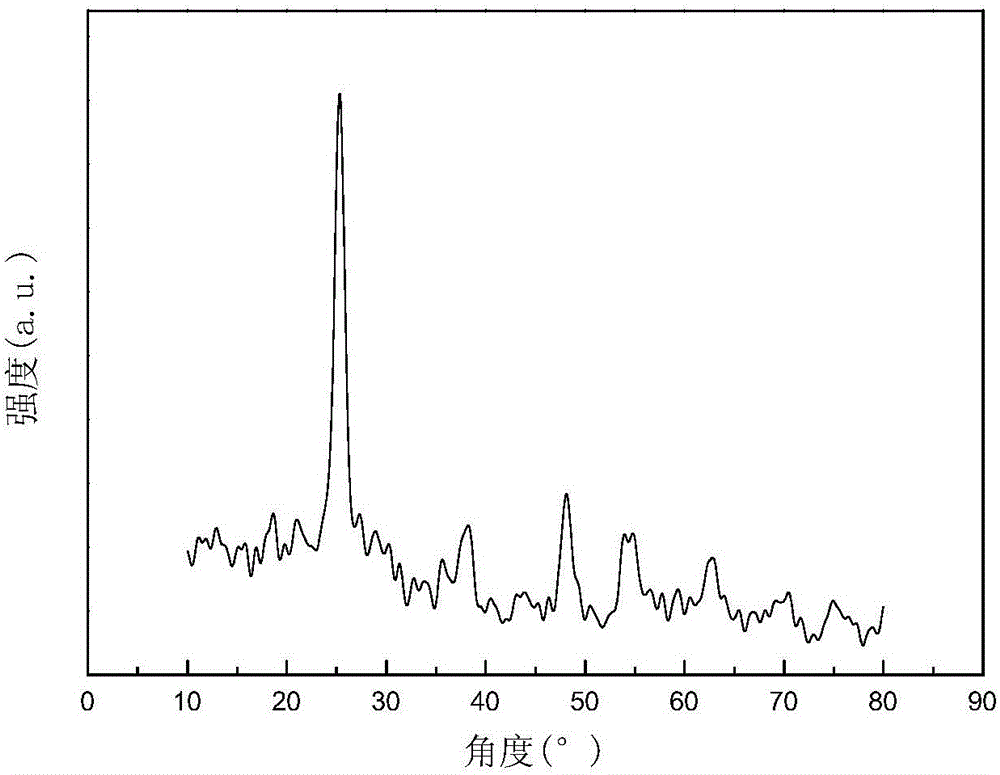

[0030] Specific embodiment one: a kind of magnetically loaded TiO described in this embodiment 2 The preparation method of composite photocatalyst material is specifically carried out according to the following steps:

[0031] 1. Preparation of Fe 3 o 4 particle

[0032] FeCl 3 ·6H 2 O. Dissolve polyvinylpyrrolidone and sodium acetate in ethylene glycol, stir at a stirring speed of 180r / min to 360r / min for 1h to 2h to obtain a mixed solution, put the mixed solution in a polytetrafluoroethylene reactor, and React at a temperature of 180°C to 200°C for 6h to 10h, then cool down to room temperature, wash with deionized water for 3 to 5 times, then wash with absolute ethanol for 3 to 5 times, and finally at a temperature of 45°C to 60°C Drying for 6h ~ 10h under the hood to obtain Fe 3 o 4 particle;

[0033] The FeCl 3 ·6H 2 The mass ratio of O to polyvinylpyrrolidone is 1:(1~3); the FeCl 3 ·6H 2 The mass ratio of O and sodium acetate is 1:(0.5~1.5); The FeCl 3 ·6H 2...

specific Embodiment approach 2

[0045] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the FeCl described in step one 3 ·6H 2 The mass ratio of O to polyvinylpyrrolidone is 1:(1-2). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0046] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the FeCl described in step one 3 ·6H 2 The mass ratio of O to sodium acetate is 1: (0.5-1). Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com