Automobile spare tire cover-plate

An automobile spare tire cover and cover technology, which is applied in vehicle parts, layered products, transportation and packaging, etc., can solve the problems of durability, safety and comfort, environmental protection and economy, spare tire cover Problems such as heavy weight and limited bearing capacity, to achieve the effect of improving sound insulation and heat insulation capacity, light weight and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further elaborated:

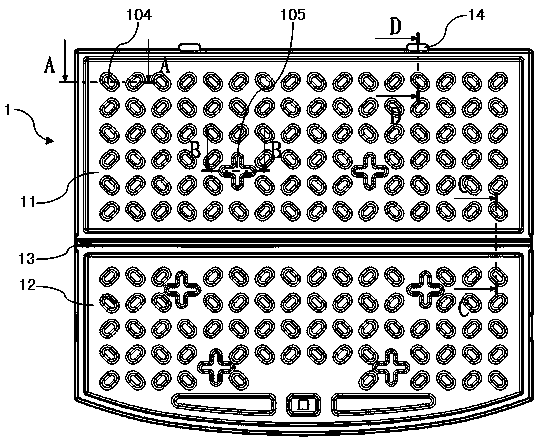

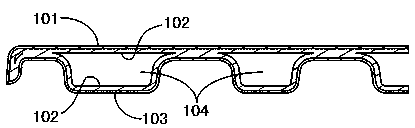

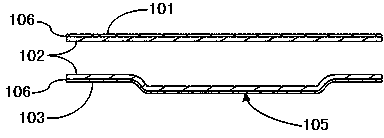

[0019] like Figure 1-5 The shown automobile spare tire cover includes a cover body 1 with a composite layer structure, and the cover body is sequentially composed of needle-punched fabric 101, two-layer PP wood powder board 102 and non-woven fabric 103 from outside to inside. The non-woven fabric is PET non-woven fabric, and the needle-punched fabric 101 and the non-woven fabric 103 are respectively bonded to the surface of the PP wood powder board through the PP film 106. The PP film is made of polypropylene material, which is environmentally friendly. Well, after thermoforming, the bond is very strong.

[0020] see figure 2 There are several cavities 104 in the hollow blow molding between the two layers of PP wood powder boards 102. The purpose of designing the cavities in the cover body is: 1. It can greatly reduce the weight of the spare tire cover; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com