Method for synthesizing 4-amino-2-chlorine-3-nitro pyridine

A technology for the synthesis of nitropyridine and its synthesis method, which is applied in the field of synthesis of 4-amino-2-chloro-3-nitropyridine, and can solve the problems of low product yield, inability to separate by column chromatography and easy volatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

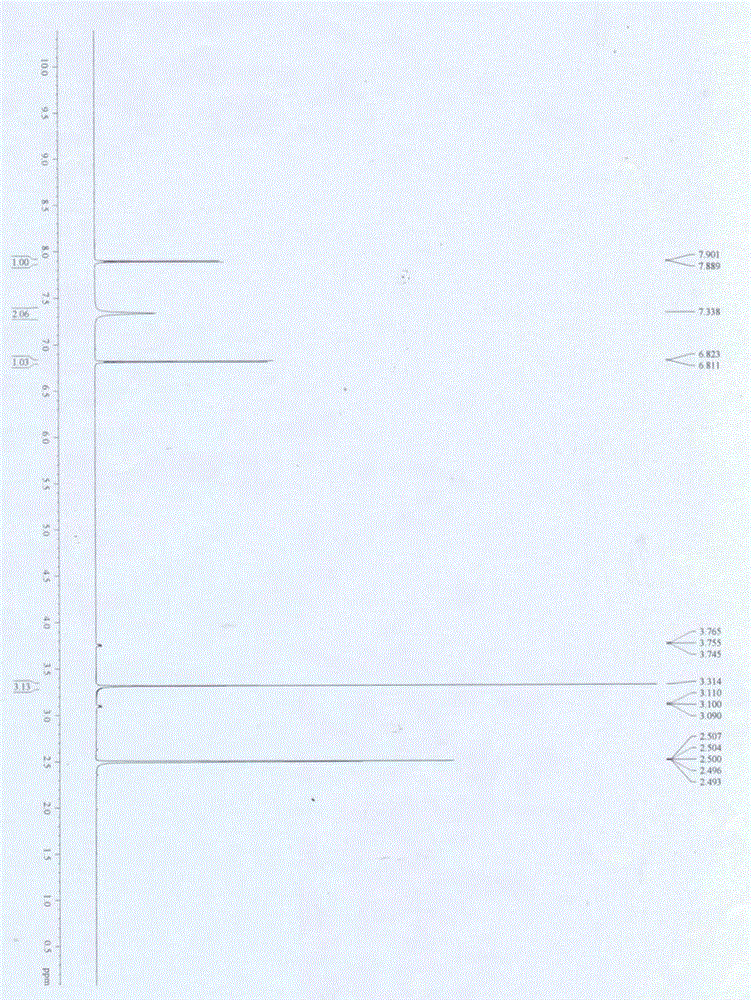

Image

Examples

Embodiment 1

[0030] Embodiment 1 A kind of synthetic method of 4-amino-2-chloro-3-nitropyridine

[0031] A kind of synthetic method of 4-amino-2-chloro-3-nitropyridine adopts 2-chloro-4-aminopyridine as raw material, and 65% nitric acid and concentrated sulfuric acid are used as mixed acid to carry out nitration reaction to prepare 4-amino-2- Chloro-3-nitropyridine generates 4-amino-2-chloro-5-nitropyridine at the same time, and the corresponding pure product is obtained after recrystallization and purification. The process is as follows:

[0032] .

[0033] Its synthetic method is carried out according to the following sequence of steps:

[0034] 1) Dissolve 200g of 2-chloro-4-aminopyridine in 1200mL of concentrated sulfuric acid at 0°C, add dropwise 1000mL of 65% nitric acid, after the addition, react at 15°C for 2h, then pour into ice In water, stir at 0°C, add NH 3 Regulate the pH to be 3, separate out white powdery solid I, filter;

[0035] 2) Dissolve the white powdery so...

Embodiment 2

[0039] Embodiment 2 A kind of synthetic method of 4-amino-2-chloro-3-nitropyridine

[0040] A kind of synthetic method of 4-amino-2-chloro-3-nitropyridine adopts 2-chloro-4-aminopyridine as raw material, and 65% nitric acid and concentrated sulfuric acid are used as mixed acid to carry out nitration reaction to prepare 4-amino-2- Chloro-3-nitropyridine generates 4-amino-2-chloro-5-nitropyridine at the same time, and the corresponding pure product is obtained after recrystallization and purification. The process is as follows:

[0041] .

[0042] Its synthetic method is carried out according to the following sequence of steps:

[0043] 1) At 0°C, dissolve 200g of 2-chloro-4-aminopyridine in 1800mL of concentrated sulfuric acid, add dropwise 1000mL of 65% concentrated nitric acid, after the dropwise addition, react at 20°C for 2h, then pour into Stir in ice water at 0°C, add NH 3 Regulate pH to be 3, separate out white powdery solid I, filter; Then,

[0044] 2) Disso...

Embodiment 3-12

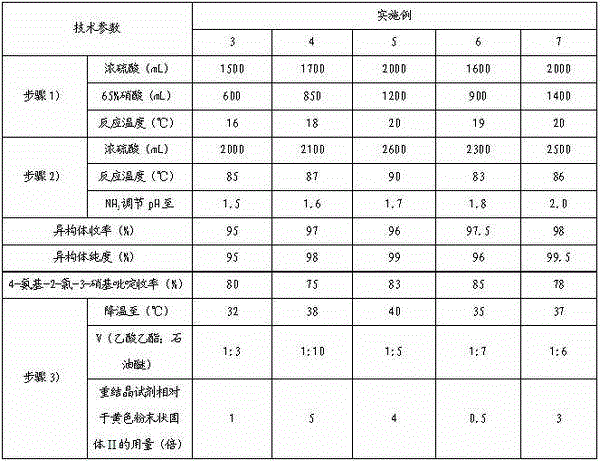

[0048] The synthetic method of embodiment 3-12 4-amino-2-chloro-3-nitropyridine

[0049] Embodiment 3-7 is respectively a kind of synthetic method of 4-amino-2-chloro-3-nitropyridine, and the difference between them and Example 1 is that the technical parameters involved in the synthetic method are different, specifically as follows Show:

[0050]

[0051]

[0052] Note: Isomer purity and yield refer to the total purity and yield of 4-amino-2-chloro-3-nitropyridine and 4-amino-2-chloro-5-nitropyridine.

[0053] Embodiments 8-12 are respectively a kind of synthetic method of 4-amino-2-chloro-3-nitropyridine, and they differ from Example 2 only in that the technical parameters involved in the synthetic method are different, specifically as follows Show:

[0054]

[0055]

[0056] Note: Isomer purity and yield refer to the total purity and yield of 4-amino-2-chloro-3-nitropyridine and 4-amino-2-chloro-5-nitropyridine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com