Method for extracting lepidium meyenii polysaccharide through subcritical water

A technology of subcritical water and maca polysaccharide, which is applied in the field of natural product active ingredient extraction, can solve the problems of high equipment requirements, high pressure resistance requirements, and long extraction time, and achieve high efficiency, low equipment requirements, and short extraction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

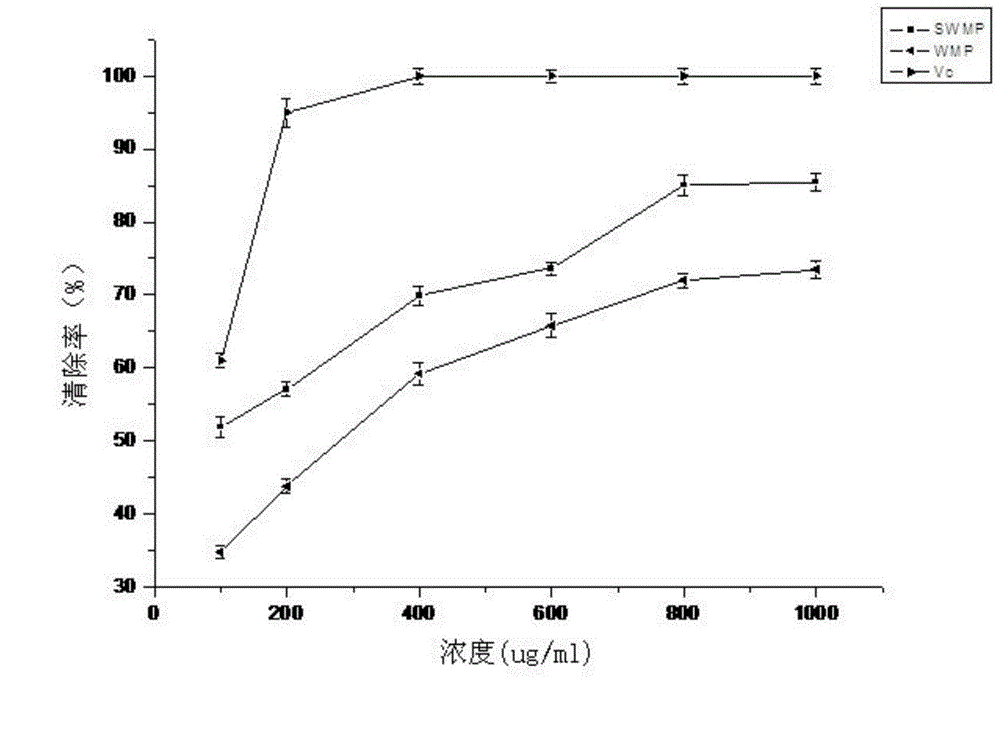

Examples

Embodiment 1

[0022] A method for extracting maca polysaccharides with subcritical water, wherein the steps of the production method are as follows: crush the dry roots of maca and pass through a 200-mesh sieve to obtain maca powder; put the prepared powder into a subcritical extraction kettle, and mix the powder with The material-liquid ratio of subcritical water is 1:10g / ml, the extraction pressure is 3MPa, the extraction temperature is 120°C, and the extraction time is 30min to obtain the extract; the extract is filtered, and the volume of the filtrate is the original 33% after concentrating under reduced pressure. %, use a 15% trichloroacetic acid solution to adjust the pH value to 1, and then refrigerate it. Refrigeration time: 4 hours, refrigerated temperature: 4°C, to obtain a refrigerated solution; centrifuge the refrigerated solution, separate the supernatant, and store it in Add ethanol to the supernatant to make the ethanol content in the solution reach 80%, refrigerate the soluti...

Embodiment 2

[0025] A method for extracting maca polysaccharides with subcritical water, wherein the steps of the production method are as follows: crush the dry roots of maca and pass through a 200-mesh sieve to obtain maca powder; put the prepared powder into a subcritical extraction kettle, and mix the powder with The material-liquid ratio of subcritical water is 1:20g / ml, the extraction pressure is 5MPa, the extraction temperature is 150°C, and the extraction time is 40min to obtain the extract; the extract is filtered, and the volume of the filtrate is 33% after being concentrated under reduced pressure. %, use a 15% trichloroacetic acid solution to adjust the pH value to 1, and then refrigerate it. Refrigeration time: 4 hours, refrigerated temperature: 4°C, to obtain a refrigerated solution; centrifuge the refrigerated solution, separate the supernatant, and store it in Add ethanol to the supernatant to make the ethanol content in the solution reach 80%, refrigerate the solution, refr...

Embodiment 3

[0028] A method for extracting maca polysaccharides with subcritical water, wherein the steps of the production method are as follows: crush the dry roots of maca and pass through a 200-mesh sieve to obtain maca powder; put the prepared powder into a subcritical extraction kettle, and mix the powder with The material-liquid ratio of subcritical water is 1:30g / ml, the extraction pressure is 10MPa, the extraction temperature is 200°C, and the extraction time is 60min to obtain the extract; the extract is filtered, and the volume of the filtrate is the original 33 %, use a 15% trichloroacetic acid solution to adjust the pH value to 1, and then refrigerate it. Refrigeration time: 4 hours, refrigerated temperature: 4°C, to obtain a refrigerated solution; centrifuge the refrigerated solution, separate the supernatant, and store it in Add ethanol to the supernatant to make the ethanol content in the solution reach 80%, refrigerate the solution, refrigerated time: 12 hours, refrigerate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com