Combined box girder sea-crossing bridge and construction method thereof

A sea-crossing bridge and construction method technology, applied in bridges, bridge applications, bridge construction, etc., can solve problems such as poor durability, weight reduction, and volume expansion, and achieve excellent overall durability, improved durability indicators, and enhanced seismic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

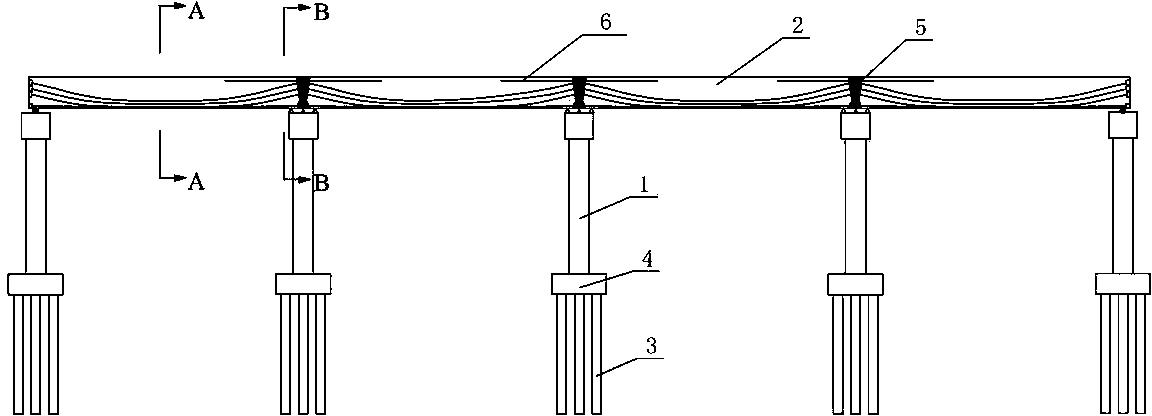

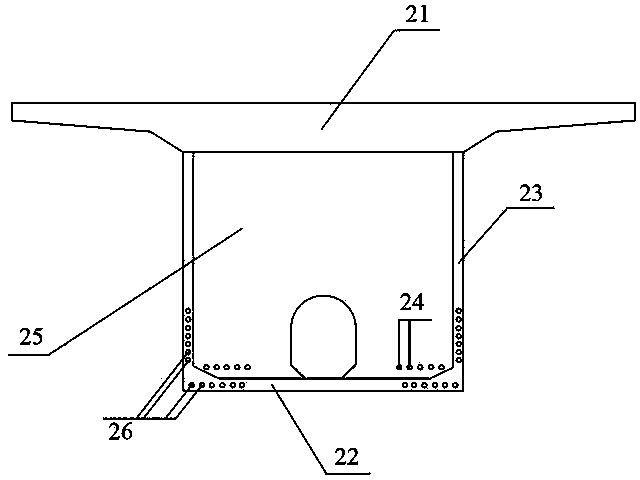

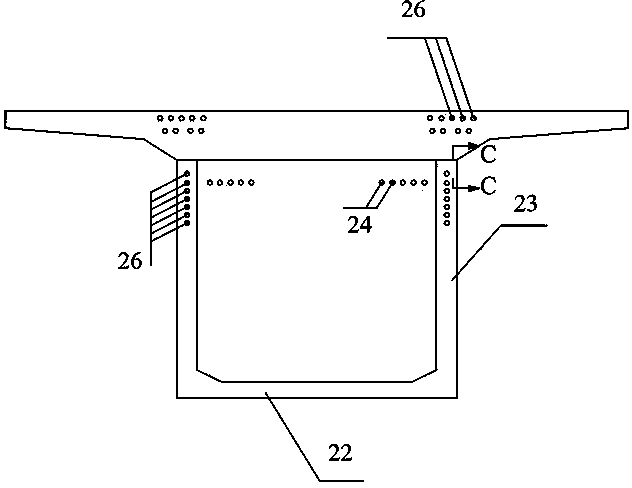

[0042] Figure 1 to Figure 4 It shows an embodiment of a combined box girder sea-crossing bridge of the present invention, which includes a bridge pier 1 and a combined box girder 2 supported by the bridge pier 1, the bottom of the bridge pier 1 is supported by a cap 4 and a pile foundation 3, and the combined box The beam 2 is surrounded by a high-strength concrete top slab 21, an ultra-high-performance concrete bottom slab 22 and a pair of ultra-high-performance concrete webs 23. Inside the composite box girder 2, there are external prestressed steel tendons 24 and internal prestressed steel tendons 26 arranged along the bridge longitudinal direction. . The combined box girder cross-sea bridge of the present invention adopts a combined box girder 2 surrounded by a high-strength concrete top plate 21, an ultra-high performance concrete bottom plate 22 and a pair of ultra-high performance concrete webs 23, an ultra-high performance concrete bottom plate 22 and a pair of The ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com