Reamed carrier and stiffness core multi-component composite pile and soft soil foundation strengthening construction method

A multi-component composite, soft soil foundation technology, applied in the direction of foundation structure engineering, sheet pile wall, soil protection, etc., can solve the problems of different bearing capacity requirements, complex stratum distribution, high efficiency, reduce land occupation, protect Ecological environment, the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

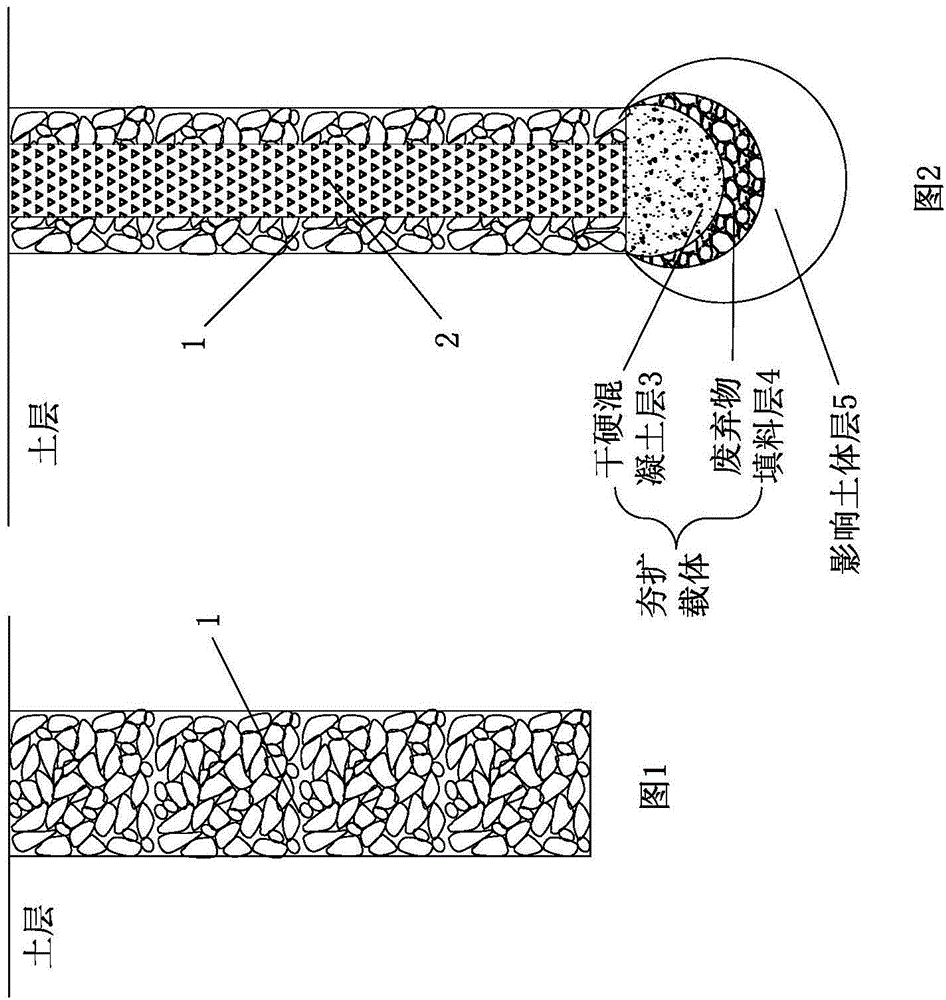

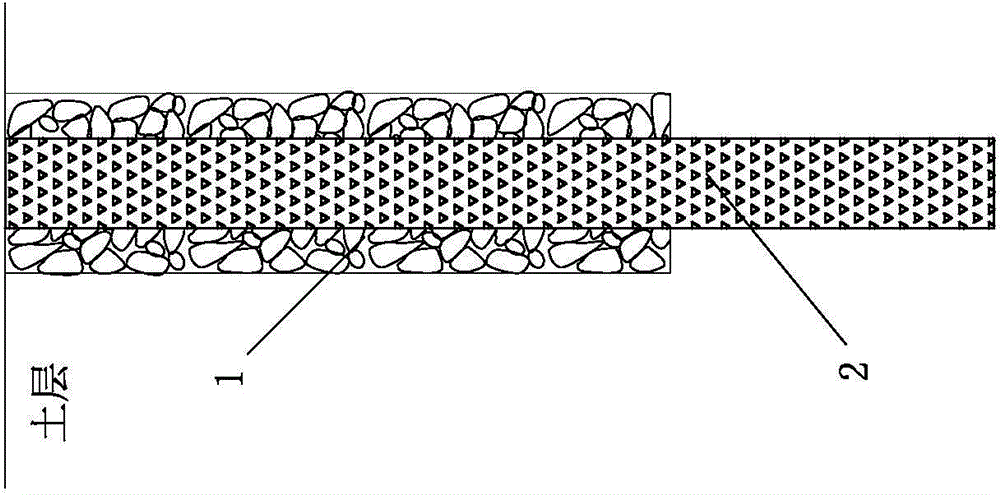

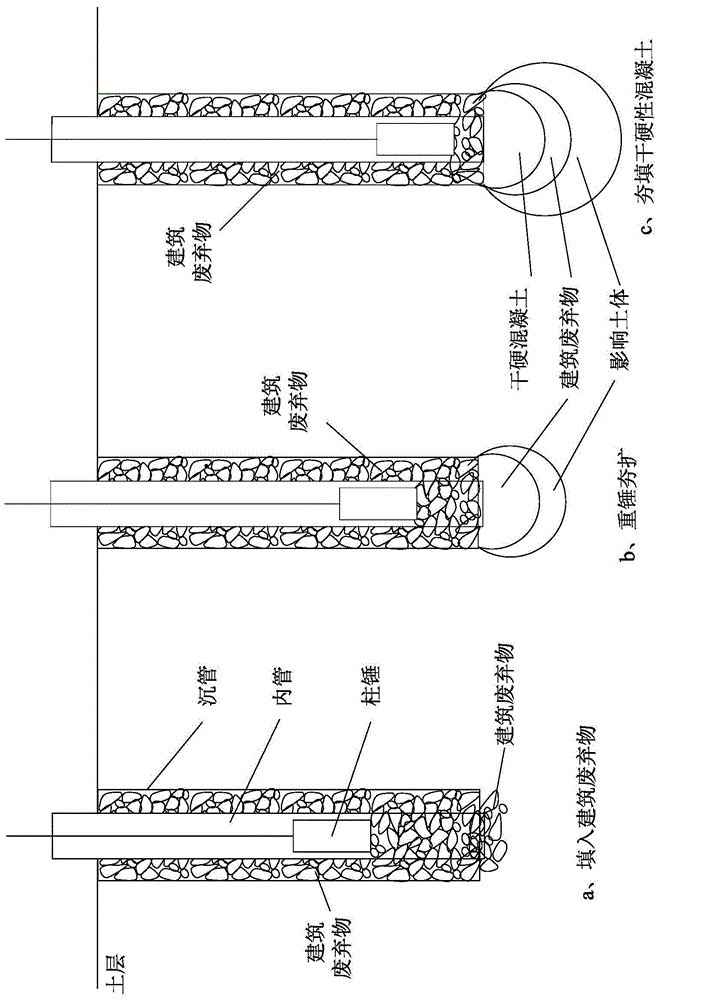

[0043] The carrier-core multi-component composite pile shown in the figure includes a bulk pile 1 that uses construction waste as a material source.

[0044] In the present invention, a rigid core pile 2 (that is, a core, usually made of reinforced concrete) is set in the above-mentioned loose pile, and the rigid core pile is vertically interspersed in the aforementioned loose pile (the core pile and the loose pile). The axis coincides), the core pile is flush with the bottom of the bulk pile; the core pile and the bottom of the bulk pile form a spherical carrier expansion head. The expansion head of the carrier is composed of the construction waste packing layer 4 covered by the outer compacted soil layer 5 and the dry hard concrete layer inside the construction waste packing layer 3 .

[0045] A construction method for reinforcing soft soil foundations with carrier-core multi-component composite piles. According to different geological conditions, several loose piles, rammed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com