A decompression and explosion-proof dust removal device for aerodynamic reservoir transformation of coalbed methane wells

An aerodynamic and reservoir reconstruction technology, applied in the directions of dust prevention, safety device, fire prevention, etc., can solve the problems of damage to the surrounding facilities of the construction site, gas explosion, loud noise, etc., to eliminate unsafe factors, prevent gas explosion, The effect of noise cancellation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

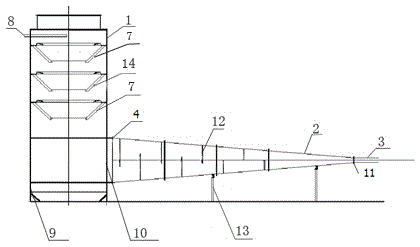

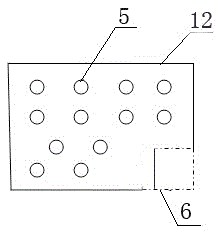

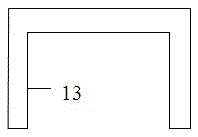

[0011] Below in conjunction with accompanying drawing, provide embodiment of the present invention as follows: figure 1 , figure 2 , image 3 , Figure 4 As shown, a kind of coalbed methane well aerodynamic reservoir transformation decompression and explosion-proof dust removal device according to the present invention is mainly composed of dust collector 1, diffuser pipe 2, and air intake pipe 3; Welded thick steel plate. The dust collector 1 has an overall height of 7000mm and a diameter of 2400mm. It is divided into upper, middle and lower sections, and each section is connected together with bolts. The height dimension of the lower section of the dust collector 1 is 2600mm, and one side of the lower section is provided with an air inlet 10, and the air inlet 10 and the diffuser pipe 2 are connected by bolts through the diffuser pipe connection port 4. The bottom of the lower section of the dust collector 1 is welded with a first-stage vane-type swirl plate tray 7 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com