Electric vehicle shift mechanism

A technology of shifting mechanism and electric vehicle, applied in mechanical equipment, transmission device, automatic clutch, etc., can solve the problems of high installation accuracy, difficult to achieve the best efficiency point, control system damage, etc., so as to eliminate control system damage. , The effect of convenient shifting and simple shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

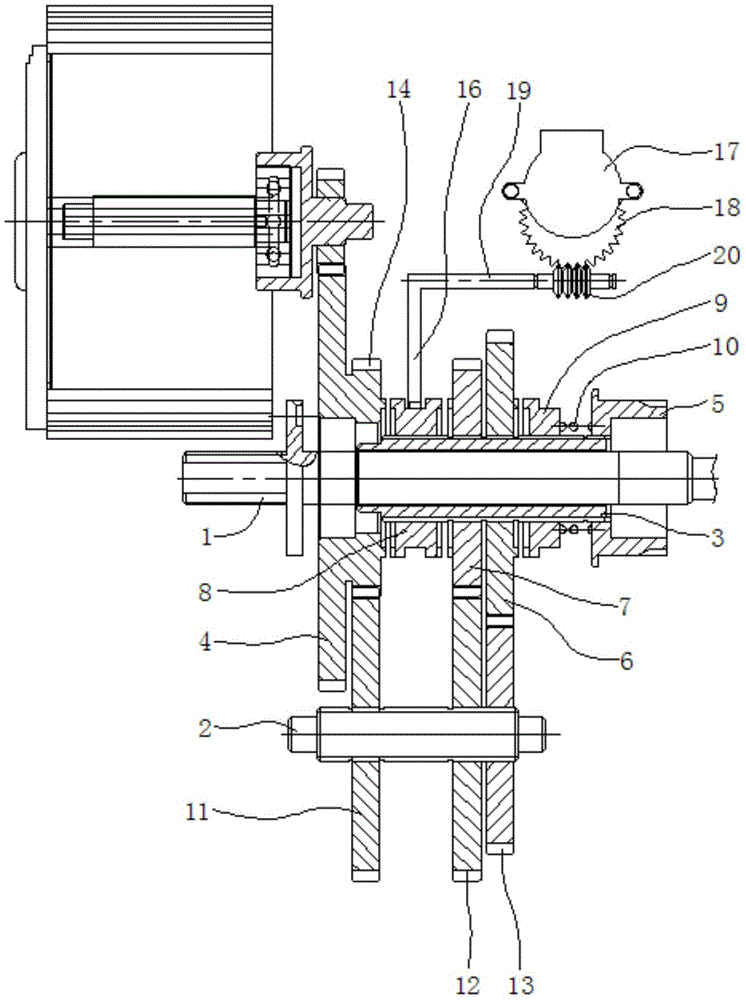

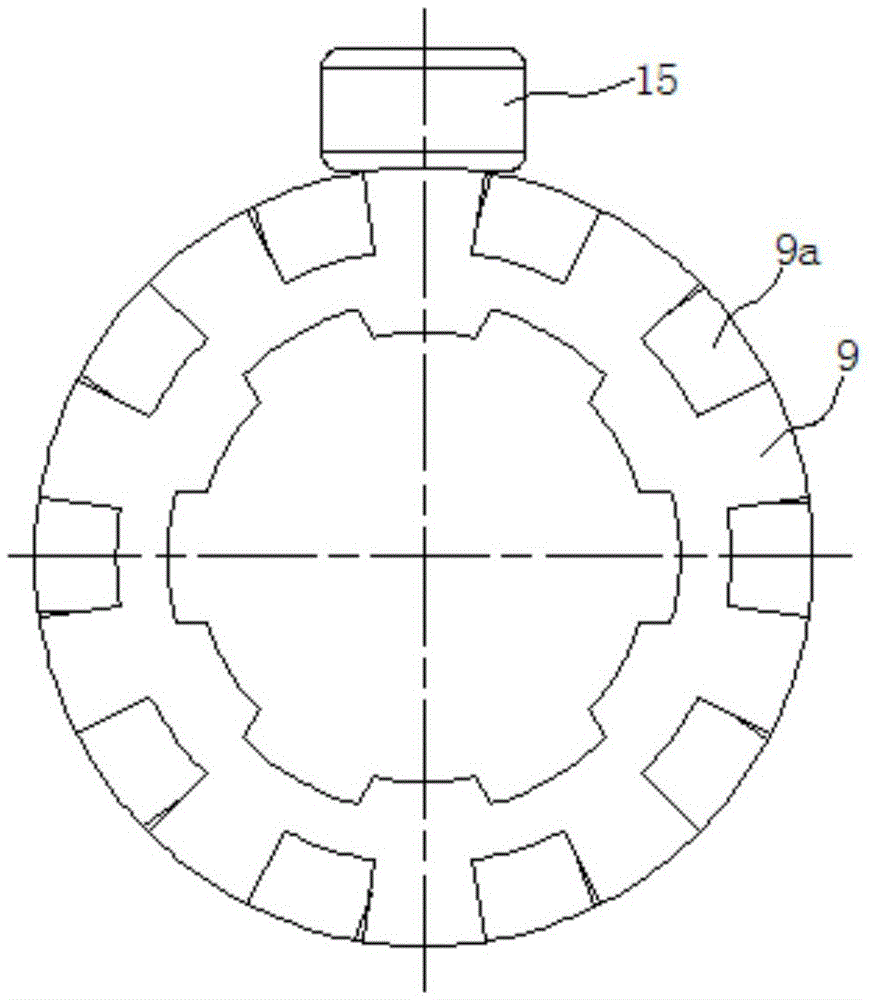

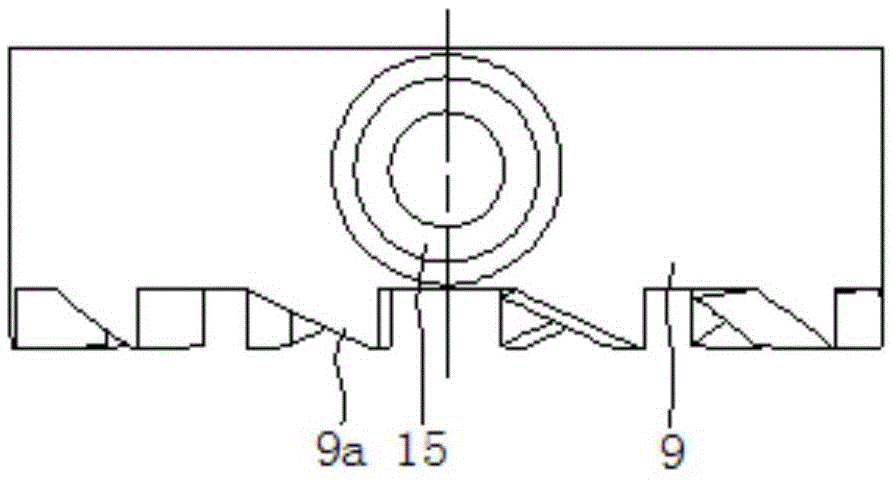

[0028] Such as figure 1 As shown, the main shaft 1 connected with the electric vehicle body is fixed, the main shaft 1 is parallel to the auxiliary shaft 2, and the auxiliary shaft 2 can rotate freely. A transmission sleeve 3 is sheathed on the main shaft 1 , and the transmission sleeve 3 can rotate relative to the main shaft 1 . Described transmission shaft sleeve 3 is as shown in the figure the left end of peripheral empty sleeve third gear 4, the right end of this third gear 4 is provided with secondary deceleration driving gear 14, secondary deceleration driving gear 14 and third gear 4 can be an integral structure, It can also be a split structure fixed together. The right end of the transmission shaft sleeve 3 is connected with the output spline sleeve 5, the output spline sleeve 5 is set on the transmission shaft sleeve 3 through the spline, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com