Particle drying machine

A particle drying and motor technology, which is applied in the direction of dryers, drying, lighting and heating equipment, etc., can solve the problems of large loss and achieve the effects of small loss, easy promotion and use, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

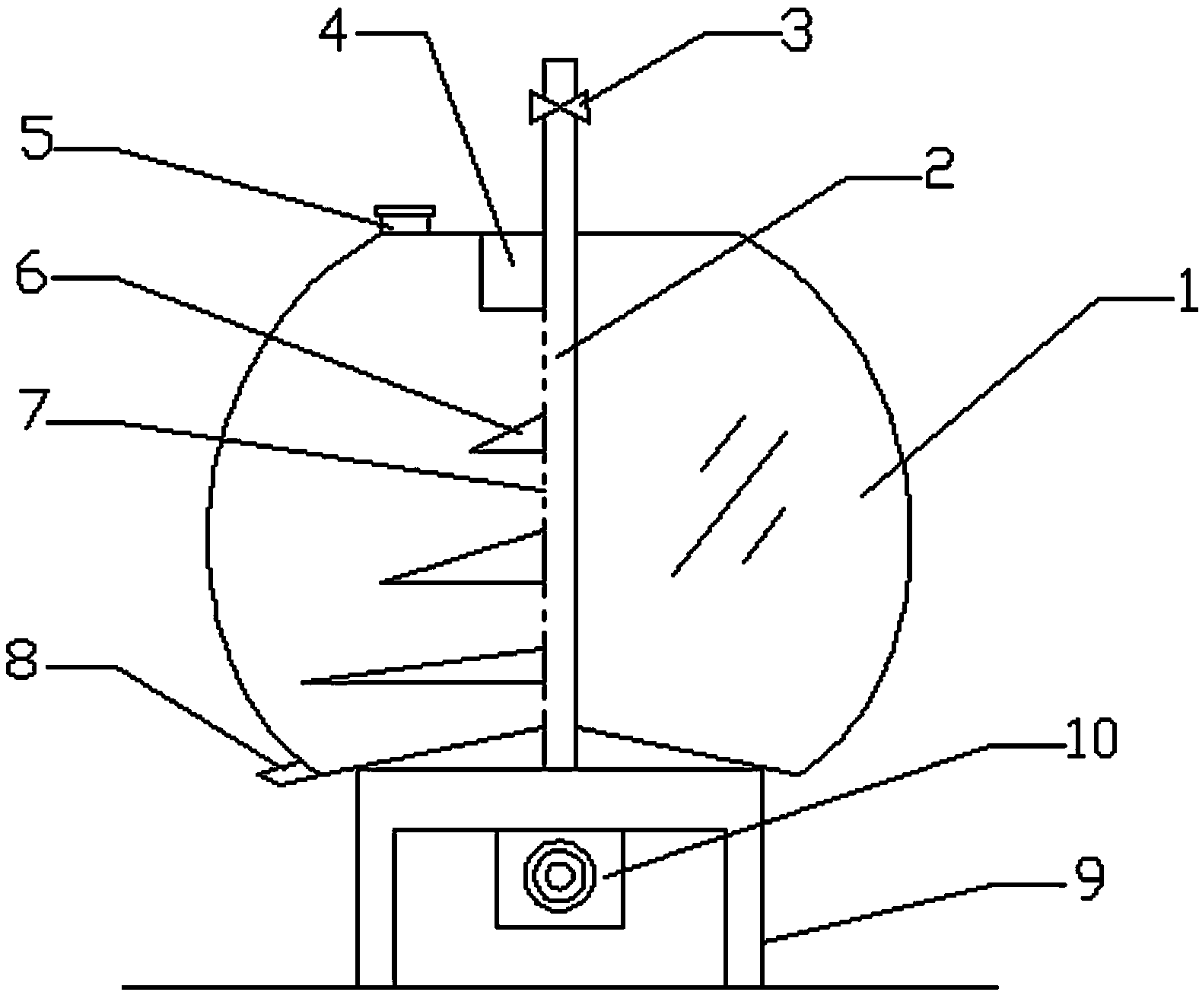

[0014] Such as figure 1 As shown, a particle dryer includes a box body 1 and a bracket 9, the box body 1 is supported on the bracket 9; it also includes a stirring shaft 2, a feed channel 4 and a discharge channel 8, the stirring shaft 2 passes through the box body 1 The interior is fixedly connected with the motor 10, the motor 10 is fixed on the bracket 9, and the stirring shaft 2 located in the upper part of the box 1 is provided with a valve 3 for controlling the flow rate of the air flow. The valve 3 is fixedly connected with the hot air blower; The stirring shaft 2 is provided with a plurality of stirring paddles 6 and pore groups 7 distributed at intervals. Each stirring paddle 6 is in the shape of a cone, and the bottom radius increases sequentially from top to bottom; the feed channel 4 is fixed on the top of the box 1 , The bottom of which is a screen; the discharge channel 8 is provided at the junction of the bottom and the side of the box body 1; the top of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com