Vacuum prepressing-overloading-dynamic compaction combined consolidometer

A preloading and vacuum technology, applied in the field of geotechnical engineering, can solve the problems that the vacuum degree is difficult to reach the deep soil, it is difficult to meet the practical application of engineering, and the loss of vacuum degree along the way is large, so as to achieve good consolidation drainage effect and shorten the solidification time. The effect of shortening time and increasing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

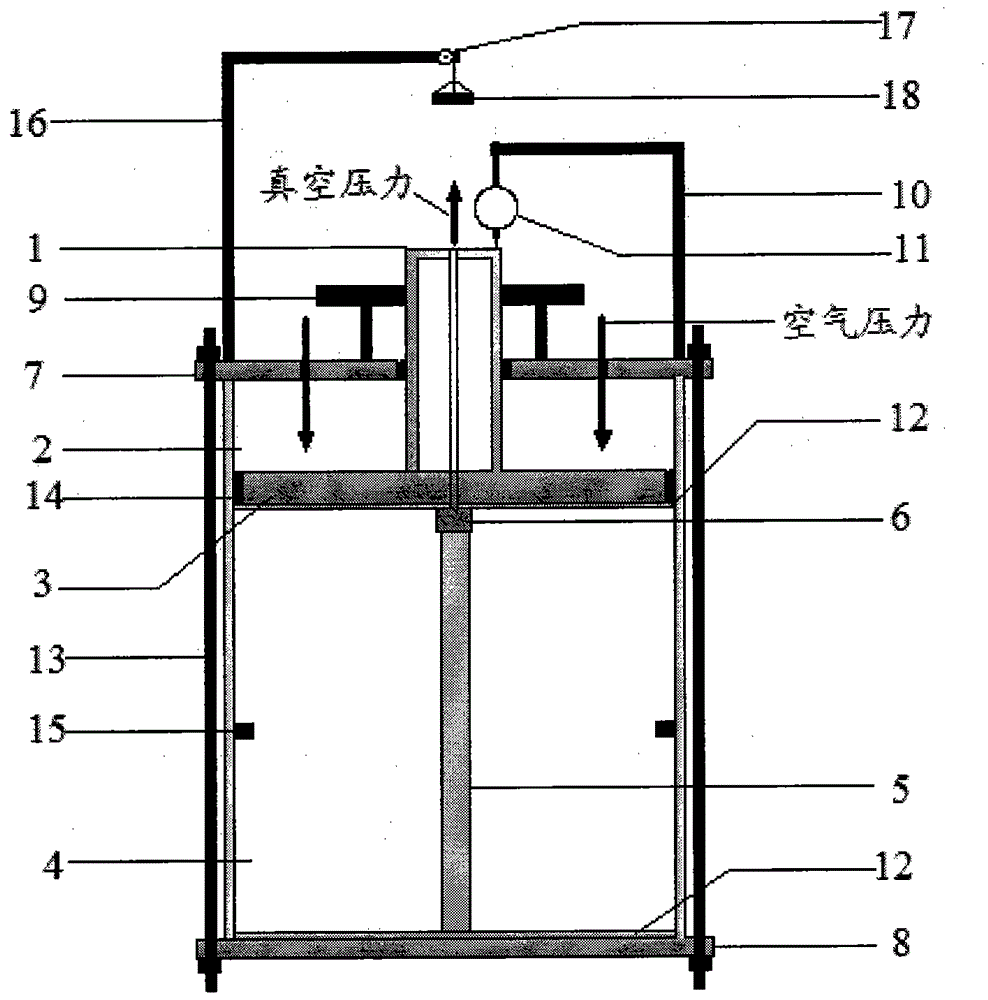

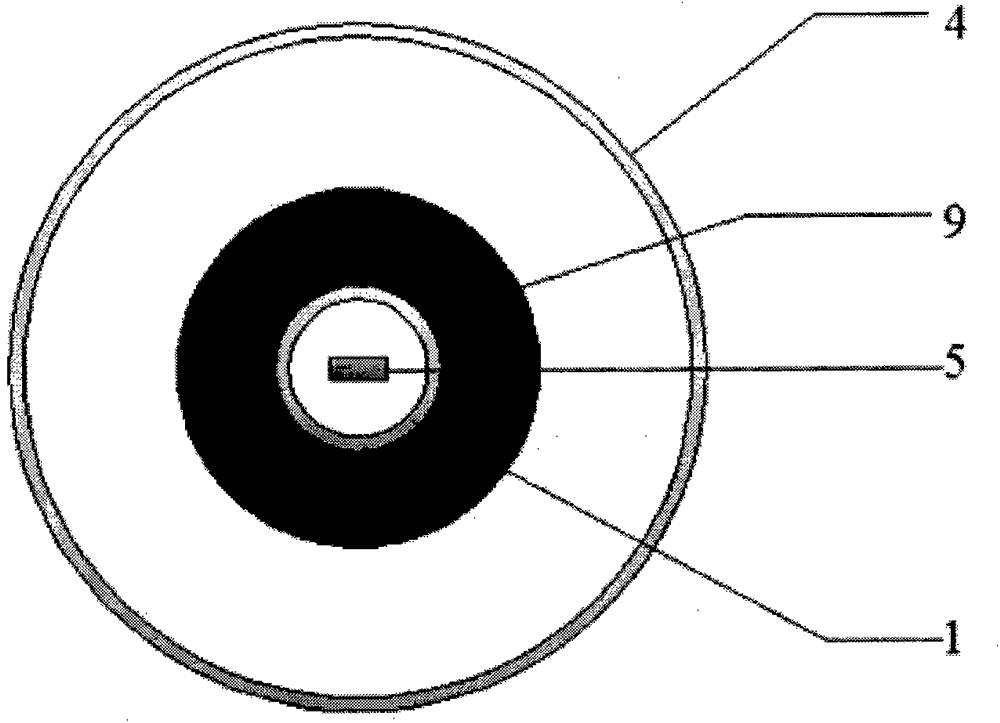

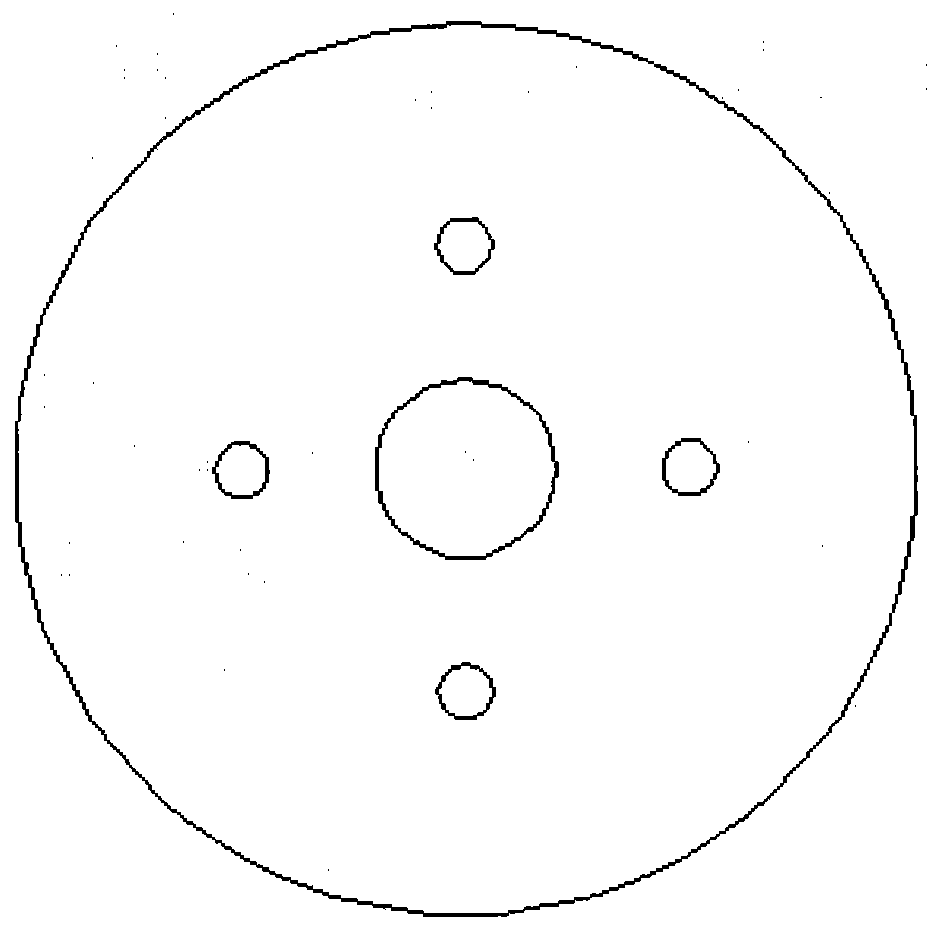

Embodiment 1

[0021] Embodiment 1, the outer wall of the soil sample chamber 4 and the air pressure chamber 2 is a cylindrical cavity made of polyvinyl chloride (PVC), the cavity height is 1000mm, the inner diameter is 500mm, and the wall thickness is 10mm; The piston 3 separating the air pressure chamber 2 and the soil sample chamber 4 is made of alloy material with a thickness of 35 mm, and a hole with a diameter of 5 mm is left in the middle for the passage of the drain hose between the drain plate cap 6 and the piston connection chamber 1; the air pressure chamber 2. The top cover 7 is made of steel, with a diameter of 600 mm and a thickness of 10 mm. A circular channel with a diameter of 100 mm is left at the center of the top cover 7 for hooping on the outer wall of the piston connecting chamber 1. The distance between the top cover 7 and the center of the circle is 150 mm. There are four holes with a diameter of 6mm in two orthogonal directions, and the four rubber hoses respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com