Method for driving high-temperature liquid metal to flow circularly to cool internal components of reactor

A technology of liquid metal and circulating flow, applied in cooling devices, reactors, reducing greenhouse gases, etc., can solve the problems of reducing system thermoelectric conversion efficiency, increasing system components and costs, etc., to achieve thermoelectric conversion efficiency, reduce electricity prices, and increase competition competitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

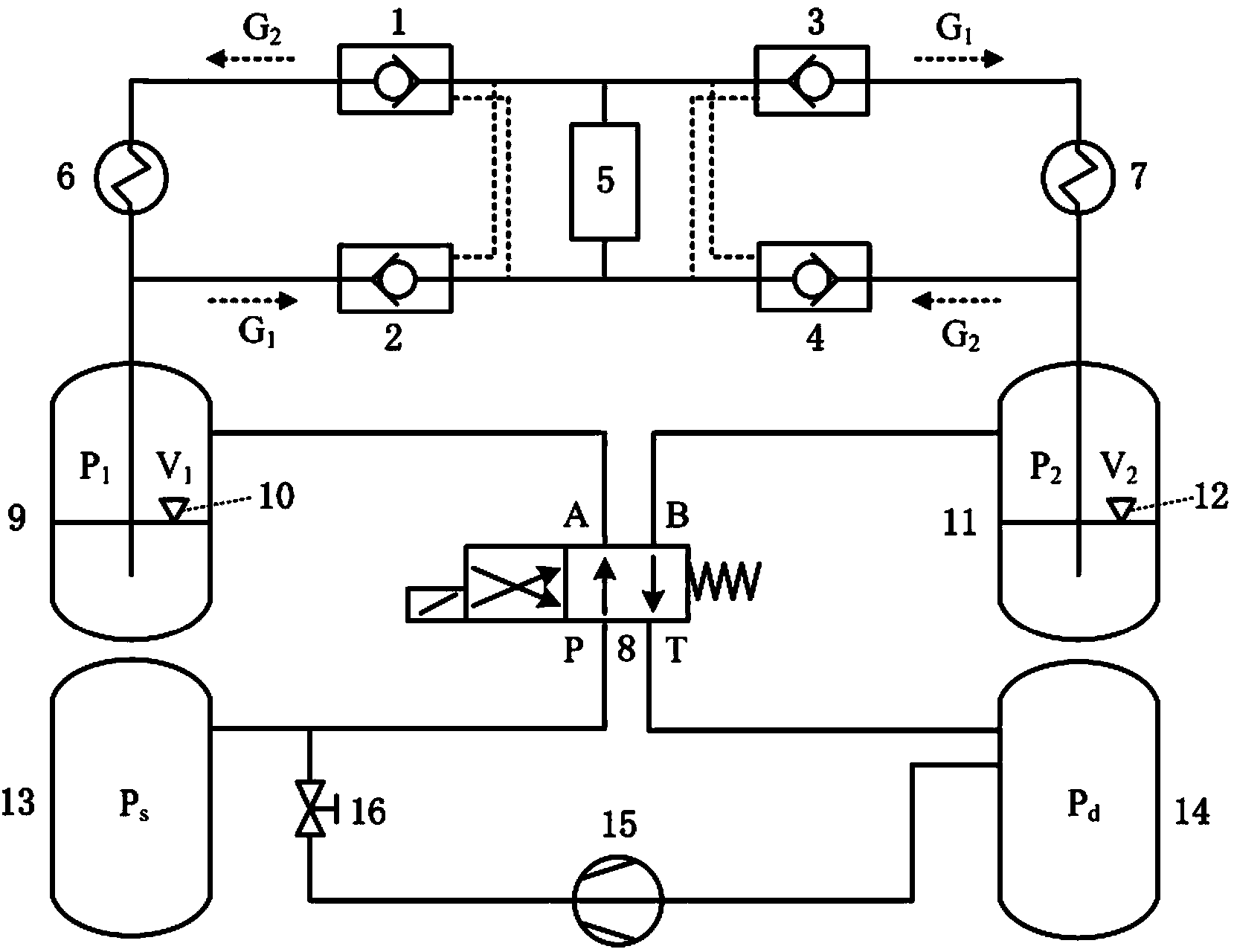

[0024] Specific embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0025] The specific embodiment of the present invention adopts the principle diagram of the liquid metal cooling reactor internal components system shown in the accompanying drawings.

[0026] Such as figure 1 As shown, in the present invention, the system using liquid metal to cool the internal components of the reactor includes a first hydraulic control check valve 1, a second hydraulic control check valve 2, a third hydraulic control check valve 3, and a fourth hydraulic control check valve 4. Internal components 5, first heat exchanger 6, second heat exchanger 7, electromagnetic reversing valve 8, first liquid metal tank 9, first liquid level gauge 10, second liquid metal tank 11, second Liquid level gauge 12, air supply tank 13, buffer tank 14, compressor 15 and valve 16. Among them, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com