Acetarious edible oil and preparation method thereof

A technology for edible oil and crude oil, applied in the field of edible oil, can solve the problems of unbalanced nutrition, poor taste, and short shelf life of salad oil, and achieve the effect of prolonging the shelf life and preventing deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

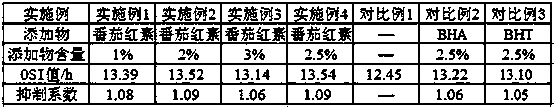

Examples

Embodiment 1

[0022] An edible oil for cold dressing, consisting of peony seed oil, wheat germ oil, sesame oil, lycopene and magnolia extract, the percentages of the quality of each raw material in the total mass of the edible oil are: peony seed oil 60%, wheat germ oil 13%, Sesame Oil 20%, Lycopene 1%, and Magnolia Extract 6%.

[0023] The preparation method of the above-mentioned edible oil for cold dressing is realized by the following steps: Step 1. Weigh a certain amount of peony seed crude oil produced by the mechanical pressing process within 1 hour, heat it to 50° C., and then add Isothermal water with 6% peony seed crude oil quality was stirred at a rate of 120 r / min for 30 minutes, then the stirring was stopped and the temperature was raised to 80° C., and then kept for 8 hours, and the water and impurities in the lower layer were separated and removed to obtain peony seed oil, which was set aside;

[0024] Step 2. Heat up the peony seed oil prepared in step 1 to 120°C, and keep s...

Embodiment 2

[0030] An edible oil for cold dressing, which is composed of peony seed oil, wheat germ oil, sesame oil, lycopene and magnolia extract. The percentages of the quality of each raw material in the total mass of edible oil are: peony seed oil 45%, wheat germ oil 14%, Sesame Oil 30%, Lycopene 2% and Magnolia Extract 9%.

[0031] The preparation method of the above-mentioned edible oil for cold dressing is realized by the following steps: Step 1. Weigh a certain amount of peony seed crude oil produced by the mechanical pressing process within 1 hour, heat it to 50° C., and then add The isothermal water with 5.5% peony seed crude oil quality is stirred at a rate of 115 r / min for 30 minutes, then the stirring is stopped and the temperature is raised to 80° C., then kept for 8 hours, and the water and impurities in the lower layer are separated and removed to obtain peony seed oil, which is set aside;

[0032] Step 2. Heat up the peony seed oil prepared in step 1 to 110°C, and keep st...

Embodiment 3

[0038] An edible oil for cold dressing, consisting of peony seed oil, wheat germ oil, sesame oil, lycopene and magnolia extract, the percentages of the quality of each raw material in the total mass of edible oil are: peony seed oil 30%, wheat germ oil 15%, Sesame Oil 40%, Lycopene 3% and Magnolia Extract 12%.

[0039] The preparation method of the above-mentioned edible oil for cold dressing is realized by the following steps: Step 1. Weigh a certain amount of peony seed crude oil produced by the mechanical pressing process within 1 hour, heat it to 50° C., and then add Isothermal water with 5% peony seed crude oil quality was stirred at a rate of 110 r / min for 30 minutes, then the stirring was stopped and the temperature was raised to 80° C., then kept for 8 hours, and the water and impurities in the lower layer were separated and removed to obtain peony seed oil, which was set aside;

[0040] Step 2. Heat up the peony seed oil prepared in step 1 to 100°C, and keep stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com