Novel solid-color multi-coating composition layer

A combination layer and coating layer technology, applied in coatings, polyester coatings, synthetic resin layered products, etc., can solve problems such as pollution, environmental pollution, and harm to human health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

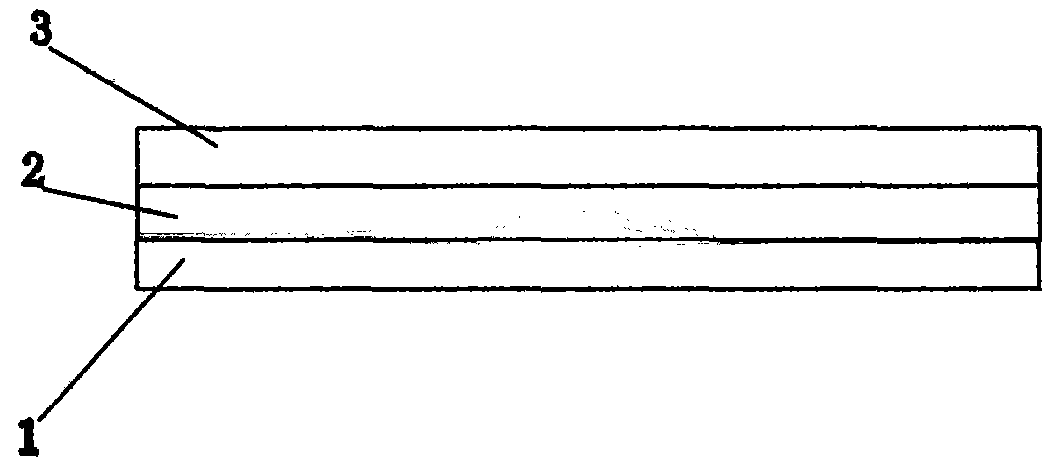

[0015] see figure 1 , a new type of multi-coating solid-color coating combination layer, the coating coating combination layer sequentially includes UV bottom layer 1, solid-color coating layer 2 and UV upper surface layer 3, the original slurry of UV bottom layer 1 is the addition of mineral powder in the UV coating original slurry It is formed by uniform stirring, and the solid-color paint layer 2 is the addition of alkyd resin with adhesion and penetration into the solid-color paint.

[0016] For further explanation of the present invention:

[0017] 1) The UV bottom layer 1 is to add mineral powder with a fineness of more than 200 meshes into the UV coating raw slurry, the volume percentage of the mineral powder is 3%-7%, the stirring temperature is required to be normal temperature, and the time is 30 minute;

[0018] 2) The mineral powder can be specifically mineral powder of silicon dioxide or calcium oxide;

[0019] 3) The solid-color paint layer 2 is specifically t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com