Physical and chemical treatment system of dangerous waste liquid

A treatment system and waste liquid technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the cumbersome and inconvenient operation process, unsatisfactory treatment effect, narrow application area, etc. problem, to achieve the effect of simple and convenient operation process, avoiding secondary pollution and personnel injury, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

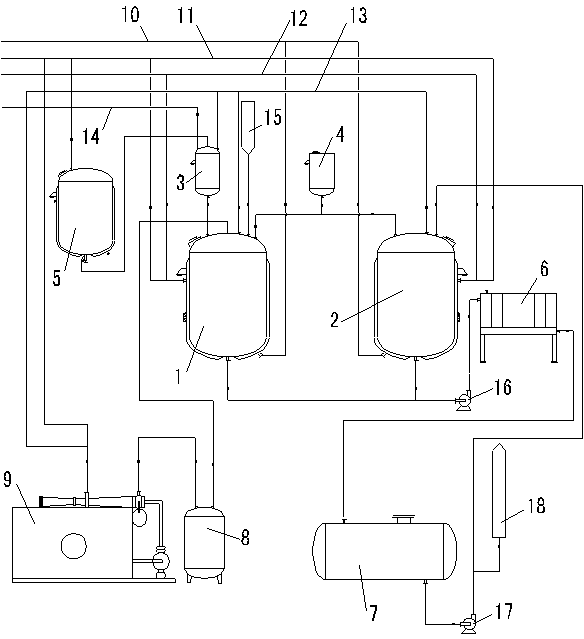

[0012] like figure 1 As shown, the physical and chemical treatment system of hazardous waste liquid of the present invention includes a primary reactor 1, a secondary reactor 2, a metering tank 3, a preparation tank 5, a dosing tank 4, a filter press 6, a filtrate tank 7, and a buffer tank 8 And vacuum pump 9 (using water ring vacuum pump). Both the primary reactor 1 and the secondary reactor 2 adopt a conventional reactor structure, which is equipped with a feed inlet, a tap water inlet, a vacuum tube interface, an observation port, a manhole, an instrument interface, and a liquid discharge port, with a jacket inside. , and is equipped with cooling circulating water pipeline and steam heating pipeline. The steam heating pipelines in the primary reactor 1 and the secondary reactor 2 are all connected with the steam main pipe 12 . The inlet and outlet of the cooling circulating water pipeline in the primary reactor 1 and the secondary reactor 2 are respectively connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com