Method for extracting macadamia nut oil by adopting subcritical extraction technology

An extraction technology, nut oil technology, applied in the field of vegetable oil extraction, can solve the problems of high equipment cost, easy oxidation and deterioration of oil, limited application, etc., and achieve the effect of high extraction efficiency, rich aroma, and clear color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

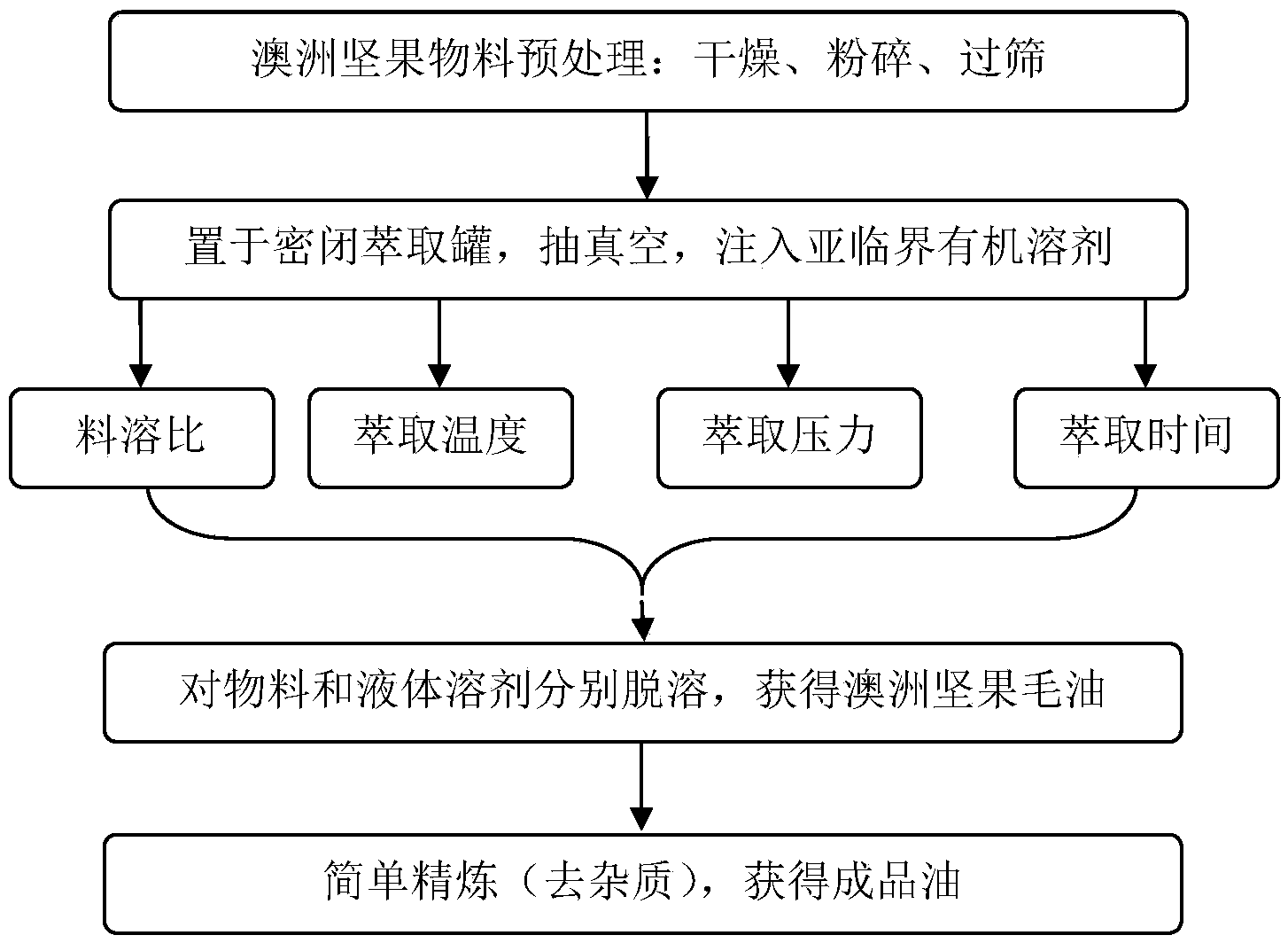

Method used

Image

Examples

Embodiment 1

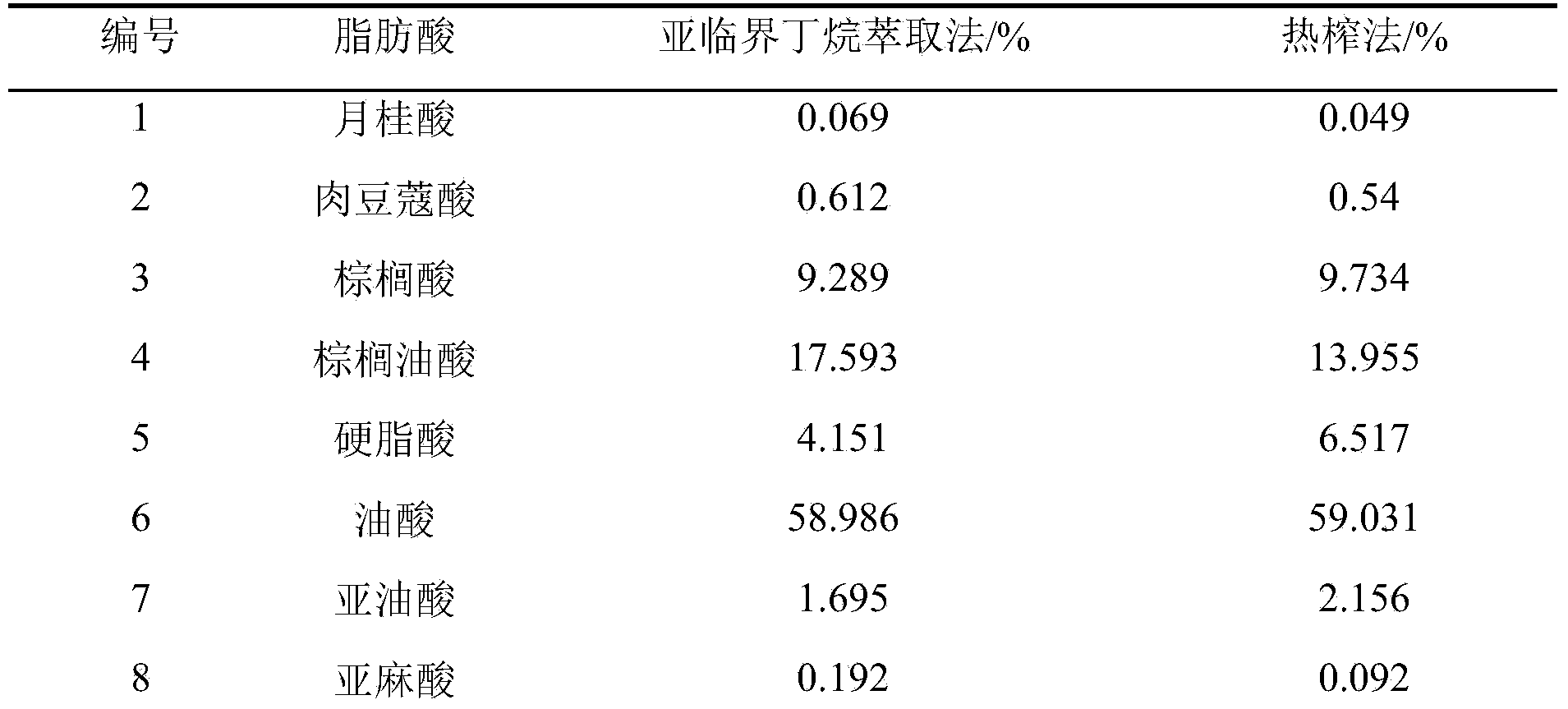

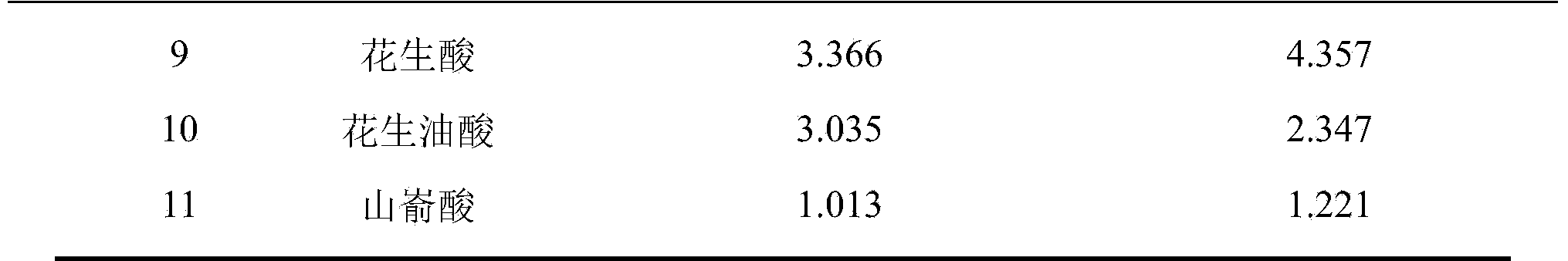

[0026] Embodiment 1 carries out according to the following steps:

[0027] After crushing the dried macadamia nut kernels to about 1mm, weigh 500g and put it in a 5L airtight extraction tank, vacuumize; inject 3L of butane solvent, completely immerse the sample, control the temperature at 45°C, the pressure at 0.45Mpa, and the time for 15min. After the extraction, put the liquid butane solvent containing macadamia nut oil into the evaporation tank, evaporate and desolventize under constant temperature and pressure at 50°C, the vaporized butane is compressed by the compressor, liquefied in the condenser and returned to the solvent tank; Open the extraction tank, take out the macadamia nut kernels, crush them to 80 mesh, put them into a closed extraction tank and repeat the above steps; after the second extraction and desolventization, do not take out the macadamia nut kernels, and proceed directly to the third extraction. After extraction and desolvation, macadamia nut crude oi...

Embodiment 2

[0042] Embodiment 2 carries out according to the following steps:

[0043] After crushing the dried macadamia nut kernels to about 1mm, weigh 300g and place it in a 5L airtight extraction tank, vacuumize; inject 2.8L of propane solvent, completely immerse the sample, control the temperature at 15°C, the pressure at 0.74Mpa, and the time for 25min. After the extraction, put the liquid propane solvent containing macadamia nut oil into the evaporation tank, evaporate and desolventize under constant temperature and pressure at 40°C, the vaporized propane is compressed by the compressor, liquefied in the condenser and returned to the solvent tank; open the extraction tank, take out the macadamia nut kernels, crush them to 80 mesh, put them into a closed extraction tank and repeat the above steps; after the second extraction and desolventization, do not take out the macadamia nut kernels, and proceed directly to the third extraction. After extraction and desolvation, macadamia nut c...

Embodiment 3

[0044] Embodiment 3 carries out according to the following steps:

[0045] After crushing the dried macadamia nut kernels to about 60 mesh, weigh 10kg, put it in a 100L closed extraction tank with stirring blades, and vacuumize it; put 60L of dimethyl ether solvent into it, completely immerse the sample, control the temperature at 25°C, The pressure is 0.61Mpa, the stirring speed is 40r / min, the time is 30min, and the frequency is 2 times. After the extraction was completed, the solvent was removed according to the method in Example 1 to obtain macadamia nut crude oil. The water was removed by vacuum evaporation and filtered to obtain 8.3 kg of macadamia nut product oil, with an extraction rate of nearly 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com