Preparation method of metal film/zinc oxide (ZnO) nanorod array fluorescence enhancement material

A technology of zinc oxide nanorods and nanorod arrays, which is applied in metal material coating technology, nano optics, nanotechnology, etc., and can solve problems such as poor fluorescence enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific implementation manner 1: The preparation method of the metal thin film / zinc oxide nanorod array fluorescence enhancement material of this embodiment is carried out according to the following steps:

[0023] 1. Substrate cleaning: use 99.5wt% acetone, 99.7wt% ethanol, deionized water with a conductivity of 18MΩ and 99.5wt% methanol to ultrasonically clean the planar substrate for 5-60 minutes;

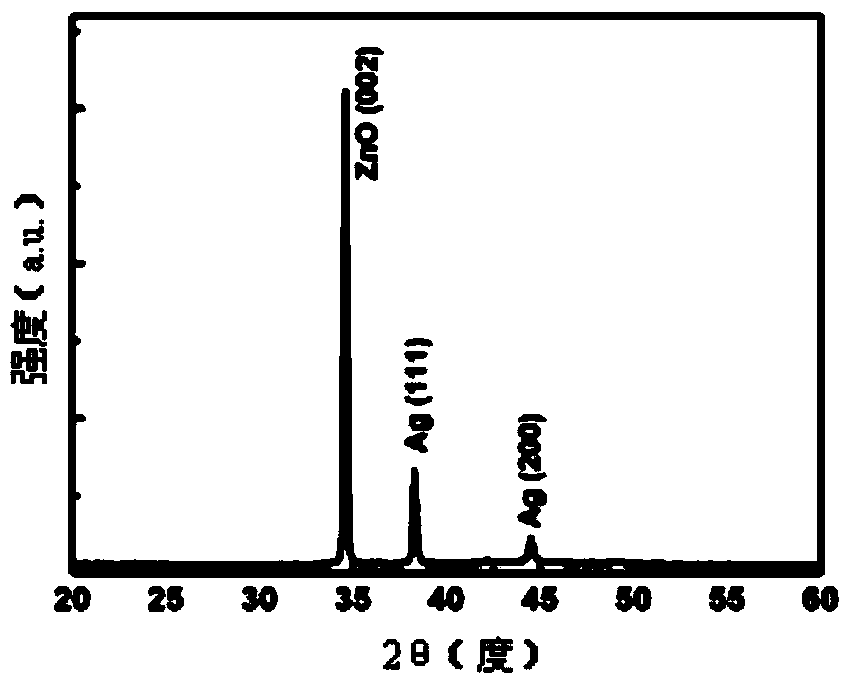

[0024] 2. Preparation of metal thin films; using magnetron sputtering, ion deposition, thermal evaporation, pulsed laser deposition, or electrochemical methods to prepare uniform metal thin films on the surface of a flat substrate;

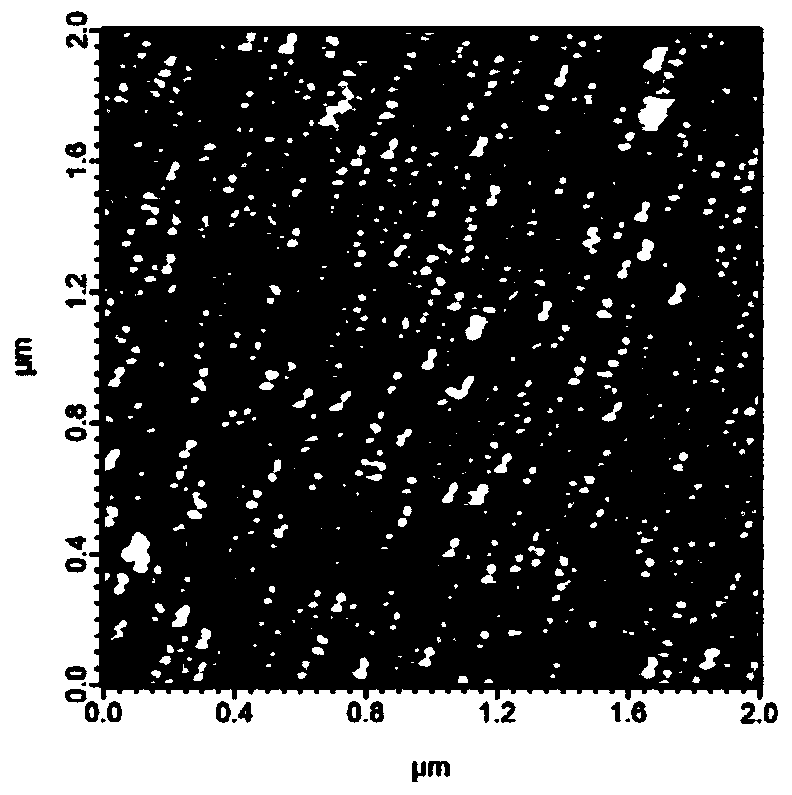

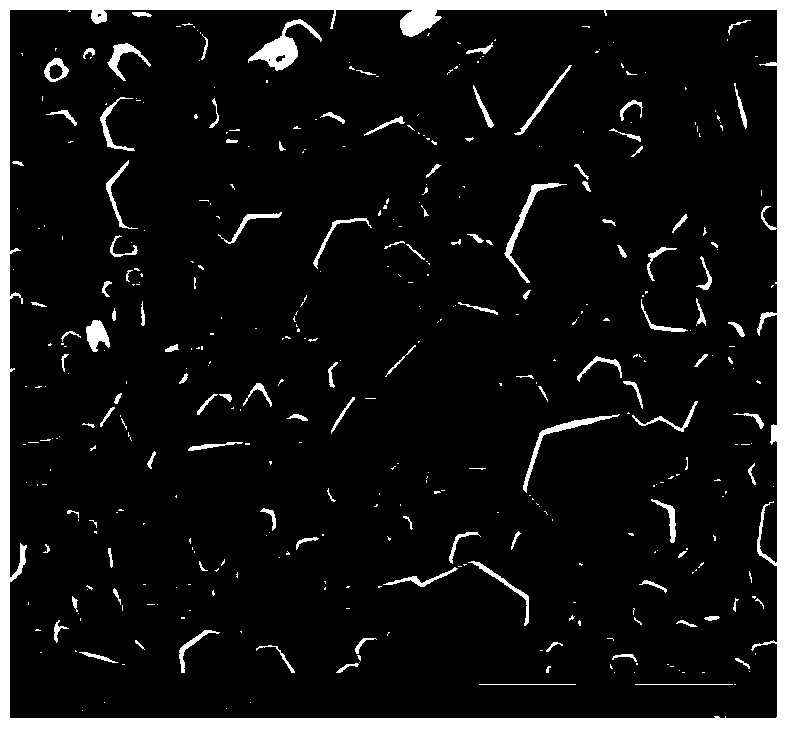

[0025] 3. Preparation of ZnO nanorod array: use hydrothermal method, pulsed laser substrate method, chemical vapor deposition method or heat transfer method to obtain ZnO nanorod array on the plane substrate processed in step 2, namely, metal film / oxidation Zinc nanorod array fluorescence enhancement material.

[0026] The detection method of the me...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and the first embodiment is that the planar substrate in step 1 is a silicon wafer, a quartz wafer, a glass wafer, PMMA, PTFE, or a sapphire wafer. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: This embodiment is different from one of specific embodiments one or two in that the metal film in step two is a silver film, a gold film, a platinum film, a palladium gold film, an aluminum film or a copper film. Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com