Tubular energy-saving closed low-voltage branch bus duct system

A busway and branch technology, which is applied in the field of low-voltage closed busbars, can solve the problems of poor natural conditions for shock resistance, loosening of screws, and decrease in current cutoff, etc., and achieves strong vibration resistance, improved electrical conductivity, and small power loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

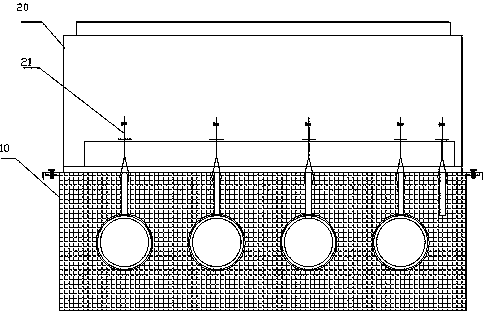

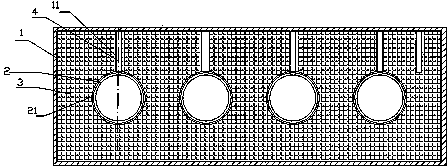

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] As shown in the figure, in order to solve the above technical problems, a tubular energy-saving closed low-voltage branch busway system of the present invention includes a housing 1, and a plurality of current-carrying conductors 2 are arranged in the housing 1, and the current-carrying conductors 2 are horizontally arranged in the housing 1 parallel to each other, the insulating resin 3 is filled between the current-carrying conductors 2, the housing 1 is provided with a socket 11, and the current-carrying conductor 1 is a round copper The outer peripheral surface of the current-carrying conductor 1 is provided with a corresponding connecting conductor 4, the connecting conductor 4 is perpendicular to the outer peripheral surface of the current-carrying conductor 1, the connecting conductor 4 is located in the corresponding socket 11, and connected The center line o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com