Stretch knitted fabric and clothes

A knitted fabric, stretchable technology, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems of limited moisture absorption and heating, no continuous heating, short heating time, etc., to prevent muscle temperature drop, heat preservation Superior, injury-preventing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

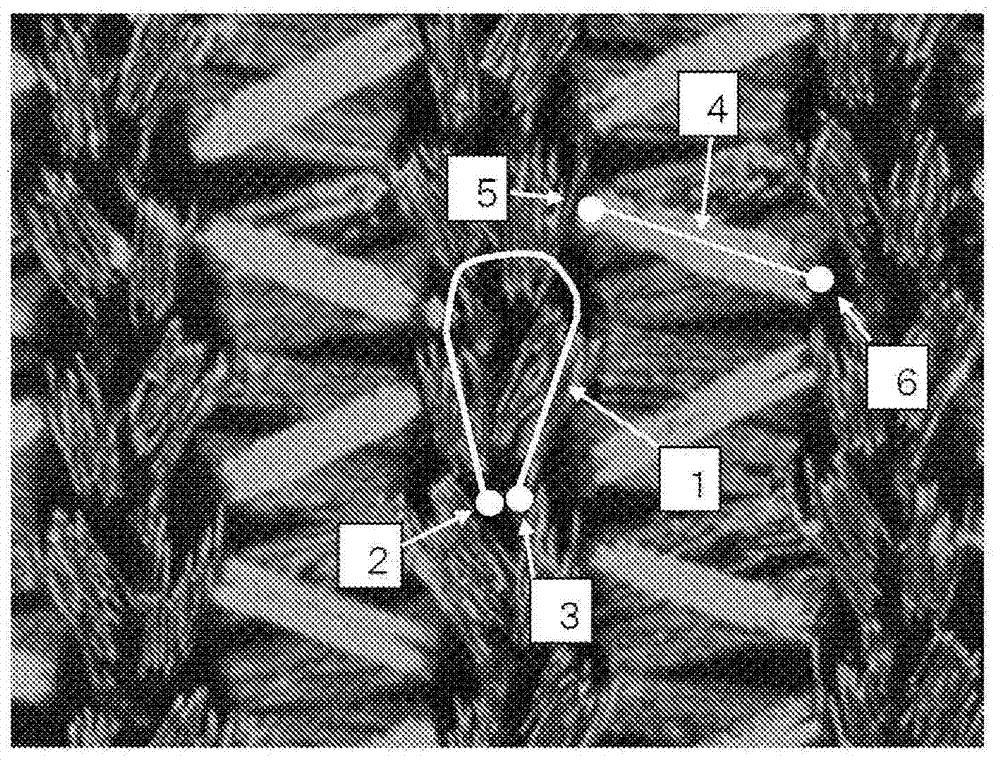

Image

Examples

Embodiment 1

[0150]Using a 32-gauge tricot machine, prepare elastic yarn 44dtex (trade name ROICACR: manufactured by Asahi Kasei Fiber Co., Ltd.) on the rear bar, and prepare nylon raw yarn 22dtex∕7f on the front bar, in the following weave , compiled under the conditions.

[0151] Front bar 10∕23

[0152] Rear comb 23∕10

[0153] The knitted fabric after knitting is relaxed and refined using a continuous refining machine (Japanese: 连続素油机), followed by presetting, that is, adjusting the width and length at 190°C for 1 minute so that the density is approximately the same as that of the gray fabric , and then, the nylon is dyed using a liquid flow dyeing machine. Fill in softening agent after dyeing, arrange and set at 170 ℃ for 1 minute with the same density as pre-setting, and make knitted fabric.

[0154] The obtained knitted fabric is a special organization, and the blending ratio of the elastic yarn is 44%, which is higher than that of the usual tricot warp knitted fabric. In additio...

Embodiment 2~ Embodiment 5

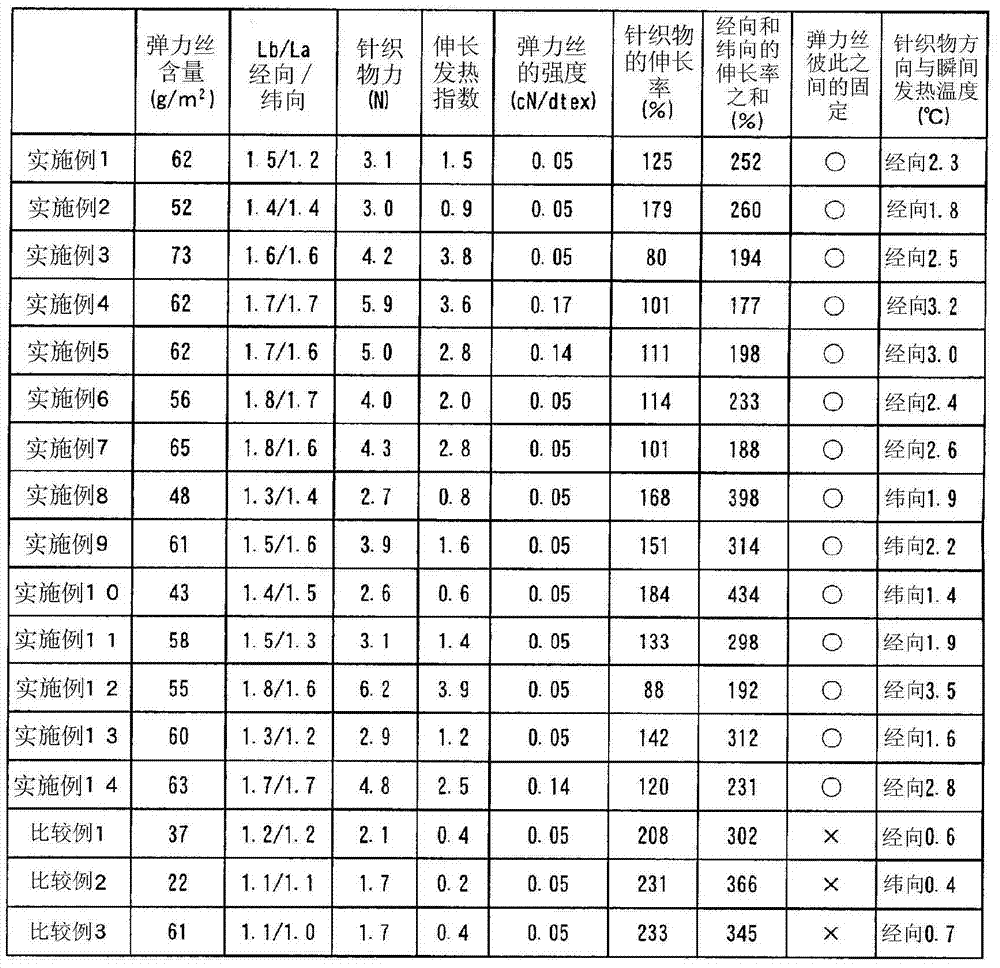

[0155] Example 2 to Example 5, Comparative Example 1

[0156] Change the fineness of the elastic yarn to 33dtex (trade name ROICA SF: manufactured by Asahi Kasei Fiber Co., Ltd.) (Example 2), change the fineness of the elastic yarn to 33dtex, and change the structure of the rear bar to 20 / 13 (implementation Example 3) In addition, the fineness of the elastic yarn was changed to 22dtex (trade name ROICA SF: manufactured by Asahi Kasei Fiber Co., Ltd.), and the structure of the rear bar was changed to 12 / 10 (comparative example 1), in addition , A knitted fabric was produced in the same manner as in Example 1, and evaluated. The results are shown in Table 1.

[0157] In addition, the polyurethane polymer (A agent) used in Example 4 of JP 7-316922 A and the polyurethane urea compound (B agent) used in Example 1 of JP 2001-140127 A were prepared, Add 7wt% A agent and 3wt% B agent (Example 4) to the spinning bath when manufacturing elastic yarn 44dtex (trade name ROICA CR: Asah...

Embodiment 6

[0160] Using a 32-gauge tricot machine, prepare stretch yarn 33dtex (trade name ROICA SF: manufactured by Asahi Kasei Fiber Co., Ltd.) on the rear bar and prepare stretch yarn 33dtex (trade name ROICA SF: Asahi Kasei Co., Ltd.) on the middle bar. Fiber (manufactured by Co., Ltd.), prepare nylon raw yarn 33dtex / 34f in the front bar, and weave it with the following weave.

[0161] Front bar 10∕23

[0162] Middle comb 10∕01

[0163] Rear comb 10∕23

[0164] The knitted fabric after knitting is relaxed and refined by a continuous refining machine, and then pre-set, that is, the width and length are adjusted at 190°C for 1 minute to make the density approximately the same as that of the gray fabric, and then dyed by liquid flow machine for dyeing nylon. Fill in softening agent after dyeing, arrange and set the shape for 1 minute under the condition of 170 ℃, and make knitted fabric.

[0165] The performance of the obtained knitted fabric was evaluated, and the results are shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com